Written by: Raul Rogerio Pimentel Ribeiro

Concept of the Control Principle

Decentralised hydrogen production system

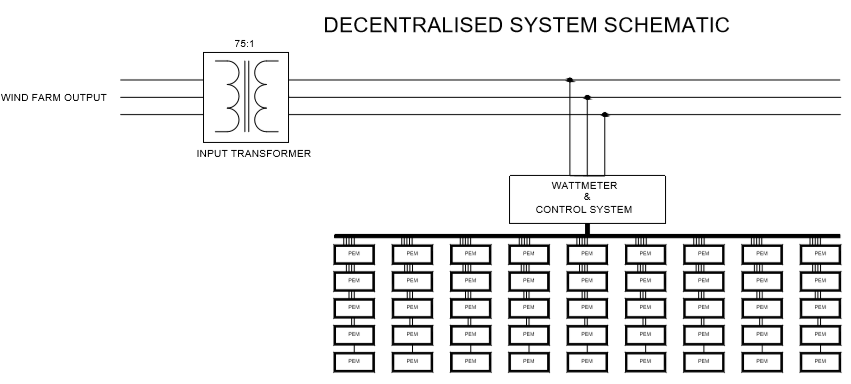

The hydrogen production is composed of 45 electrolyser stacks with the nominal power equal to 17.3 MW approximately. The principle of the decentralised system for hydrogen production consists in dividing the hydrogen production system and activate the number of electrolysers according to the amount of energy produced by the wind farm. Figure 1 illustrates a simplified approach to the proposed system.

Figure 1: Decentralised energy supply to Electrolyser system

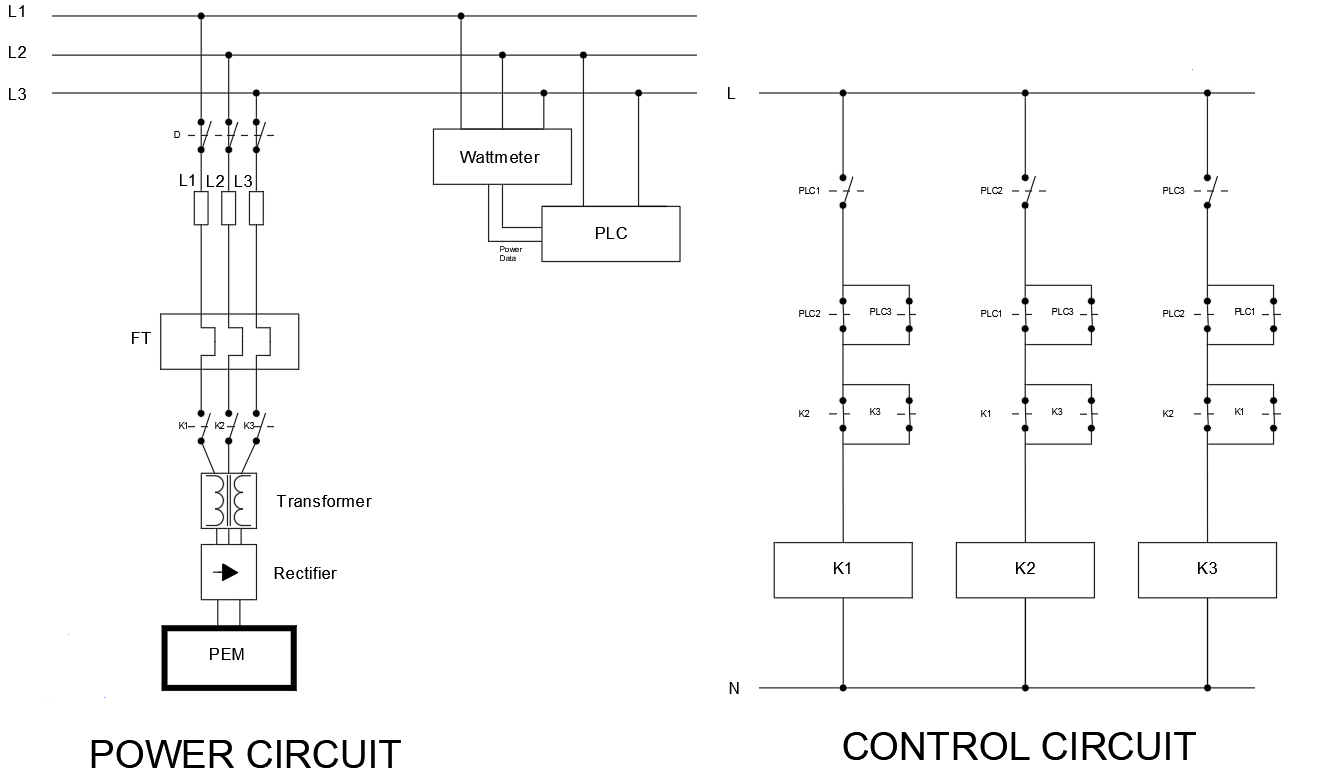

The system is controlled by a programmable logic controller (PLC) that turns the electrolysers on and off based on the reading of the wattmeter. The PLC receives the information from the wattmeter, from there, it acts by activating the compatible amount of electrolysers. In order to activate the electrolysers, the PLC closes the circuit by using power contactors. After, the energy crosses a transform and rectifier in order to match the electrolyser power requirements. Figure 2 shows the power and control circuit plant that was developed to perform the described concept.

Figure 2: Control and power circuits of the electrolyser

The idea of decentralising the production of hydrogen results in advantages regarded as system dimensioning, maintenance optimisation, production efficiency, and safety. Once the power system is split into several smaller systems, the component sizes become smaller and, in some cases, the size achieves the commercialized standard. This status collaborates to decrease the commissioning price of the system and facilitates the installation as well. The maintenance of the decentralised system is less complex and minimises the production losses. The hydrogen production is not constant at the same level, thus, the flexibility to schedule maintenance and isolate damaged systems collaborates to minimally interfere in production. Hence, the efficiency of the system tends to be maintained once the interference of interventions (such as maintenance) is mitigated. This increase of efficiency reflects in the final cost of energy and, consequently, helping the IPP to be more profitable.

Besides the technical and economic reasons, the decentralised hydrogen production system plays an important role in safety standards. According to Meier (2014), PEM electrolysers performing electrolysis within less than 50% of its nominal capacity are susceptible to generate leakages of hydrogen and oxygen. This fault generates a flammable atmosphere that can potentially conduct a hazard. The proposed system mitigates the potential of leakage due to low power capacity and maps the part of the system that can be more suitable for failure. Thus, the system supports both mitigations of hazard magnitude and identification of failure.