Written by: Luca Grispiani

Cost of Hydrogen Production

Following the definition of the Integrated Processing Platform (IPP) and the Hydrogen Production Process, it is possible to provide a general assessment of the cost of Hydrogen Production considering the whole Project.

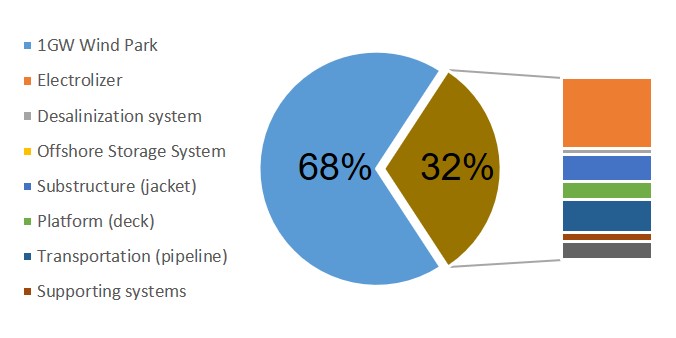

The following table lists the cost breakdown of the main macro components included this feasibility study, which is also represnted in the pie chart. It can been seen that the expenses for the whole Integrated Production Platform, that count for 32% of the overall project cost, while the remaing 2 thirds is dedicated to the Wind Farm.

Table: Project Cost Breakdown

| Item | Remarks | Cost |

| 1 GW Offshore Wind Park | LCOE Wind Park | £ 4'359'930'000.00 |

| Electrolizer System | PEM 1000£/kW | £ 780'000'000.00 |

| Desalinization System | £61,200 for a 2000L/h capacity unit | £ 63'648'000.00 |

| Offshore Hydrogen Storage System | 1,6 £ per kg H2 (pressure vessel 70MPa) 24 hours storage, incuding compression" | £ 599.040,00 |

| Platform (Deck) | (estimated) | £ 200'000'000.00 |

| Substructure (Jacket) | (estimated) | £ 300'000'000.00 |

| Transportation (Pipeline) | 0,2£/kg H2 for a 50 km Offshore pipeline | £ 346'526'200.98 |

| Supporting systems | (estimated) | £ 100'000'000.00 |

| Offloading | (estimated) | £ 200'000'000.00 |

| Total | £ 6'350'703'240.98 |

|

Figure: Pie Chart representing the Project Cost Breakdown.

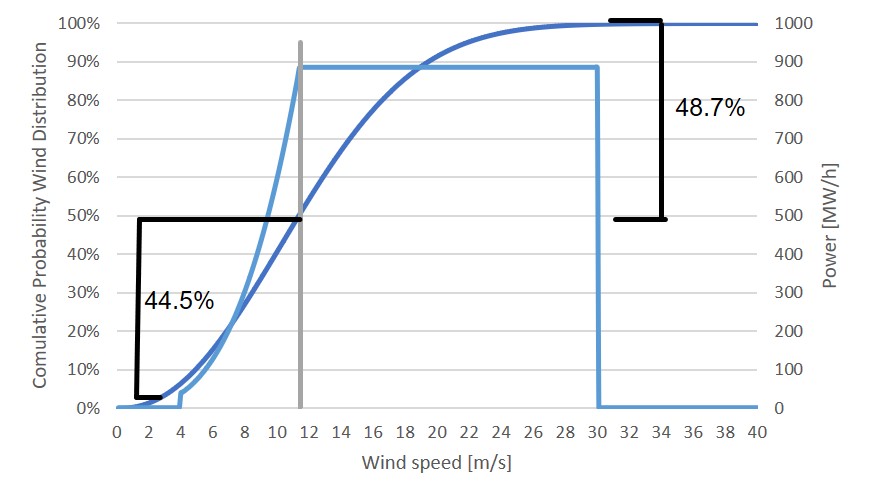

Then, the amount of hydrogen produced in a lifecycle perspective has been evaluated comparing the wind energy distribution available on site with the power output from the wind farm for a typical year. As shown in the graph below, for 48,7% of the time, Hydrogen Production Mechanism is estimated to work at the nominal power, during which it will produce 15600 H2 kg/h, while for 44,5% of the time, the production will vary according to the variation the wind speed distribution.

Anyway, based on a simplified approach, the total Hydrogen Production related to the Wind Speed included between Cut.in and rated speed values has been estimated as 30% of the production at nominal power.

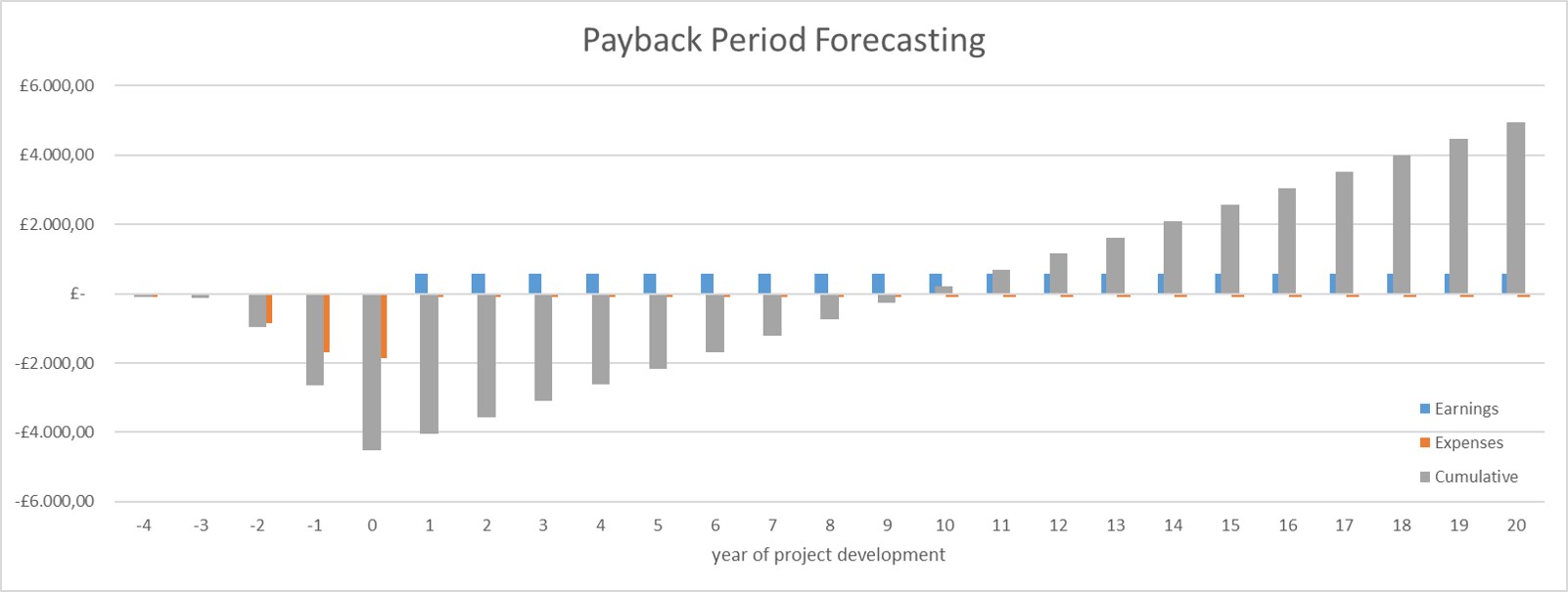

Additionally, a Payback period of 10 operation years has been considered in order to repay the capital expenditure in a time framework equal to half of operation life.

Under these design considerations, the cost of Hydrogen Production has been fixed to 6,5 £/kg of hydrogen.

Comparing this value with other energy carriers, such as Gasoline in the Automotive Industry or Natural Gas for House Heating purposes, the Offshore Hydrogen Production shows a slightly higher cost per kWh of energy.

Table: H2 Offshore Cost compared to other energy carriers.

| Unit Measure | H2 Offshore | Gasoline (Automotive) | Natural Gas (House Heating) |

| kWh/kg | 33.30 | 12,00 | 14,70 |

| £/kg | 6,50 | 1,49 | 0,26 |

| £/kWh | 0,18 | 0,124 | 0,018 |

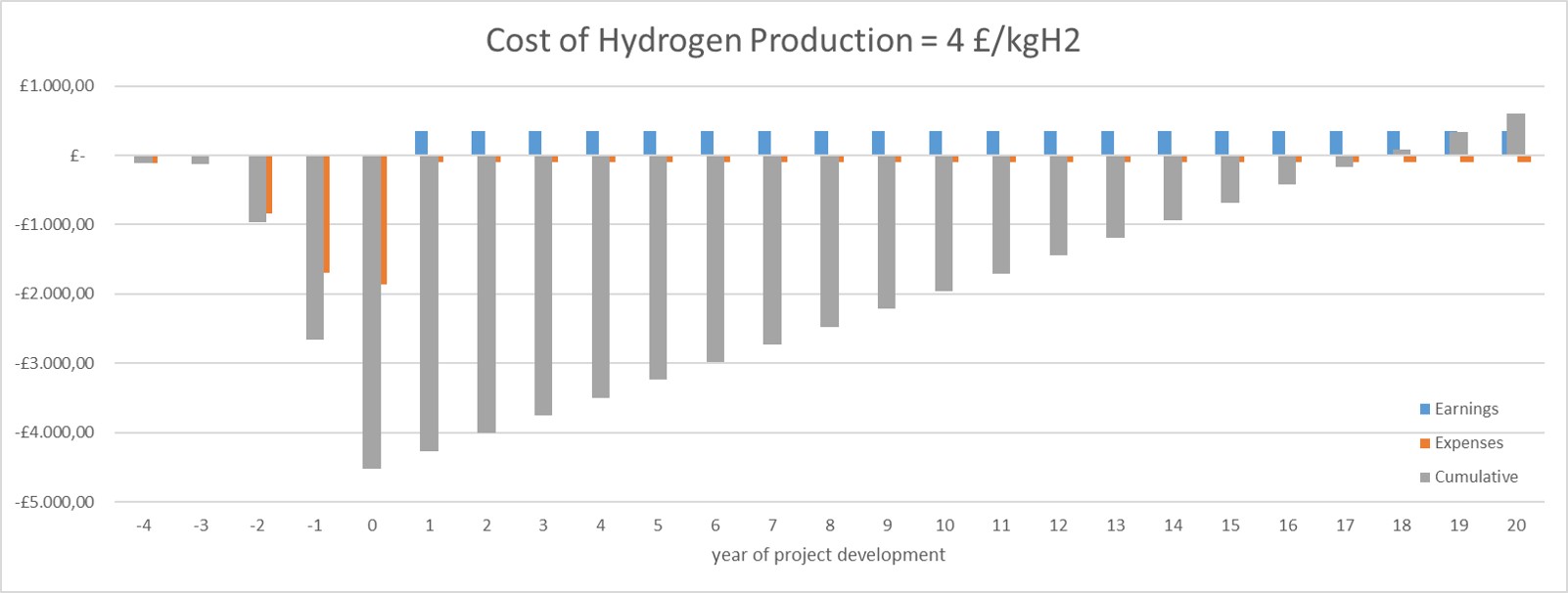

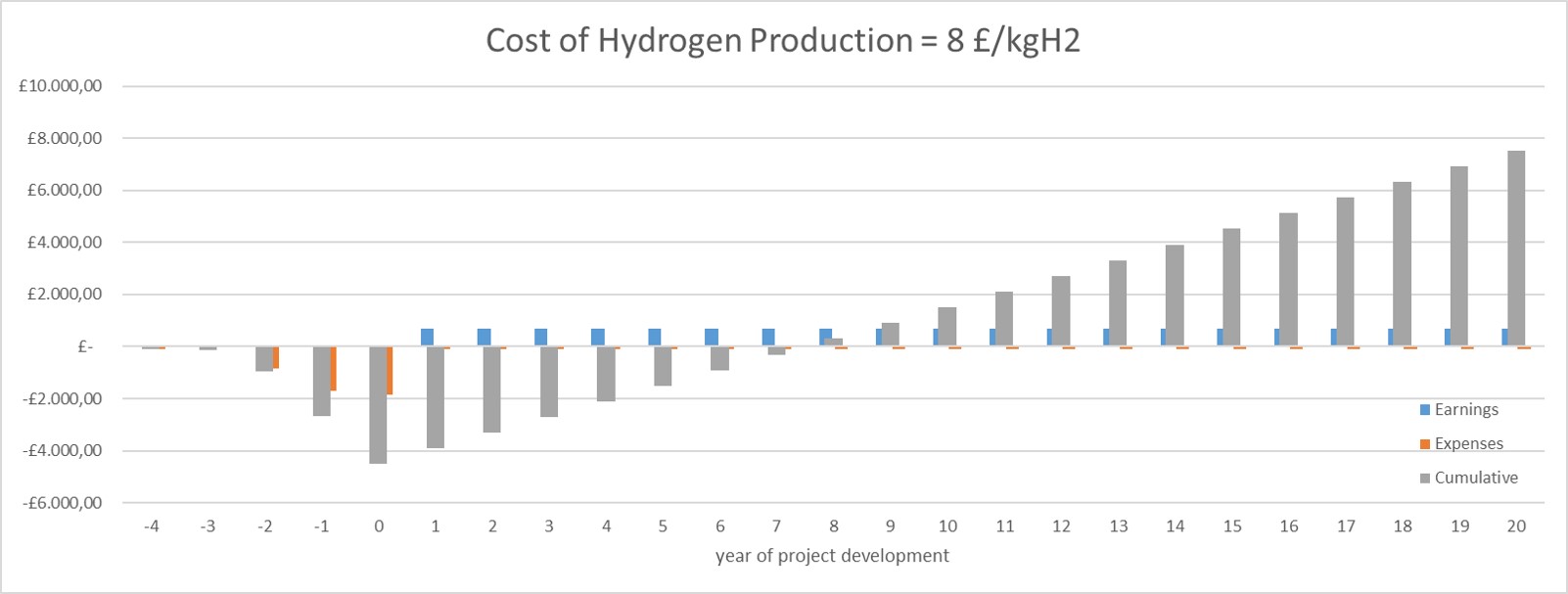

Finally, a Sensitivity Analysis has been carried out varying the hydrogen value. Hence, the next two charts show as the Payback Period tends to the Project lifecycle for a Hydrogen value of 4 £/kg, which could be considered the lowest selling price threshold.

References

Hydrogen in the Electricity Value Chain, DNV.GL, Group Technology & Research, Position Paper 2019. https://www.dnvgl.com/publications/hydrogen-in-the-electricity-value-chain-141099

North Sea Energy D3.6, Offshore System Integration – ./wp-content/uploads/2020/05/North-Sea-Energy-I-D3.1.2-3.1.4-D3.1.6-Towards-sustainable-energy-production-on-the-North-Sea_final-public.pdf

On the economics of offshore energy conversion: smart combinations. Energy Delta Institute – ./wp-content/uploads/2020/05/On-the-economics-of-offshore-energy-conversion-smart-combinations.pdf

Optimizing investments in coupled offshore wind -electrolytic

hydrogen storage systems in Denmark, P. Hou & others, Journal of Power Sources 359 (2017) 186e197, http://dx.doi.org/10.1016/j.jpowsour.2017.05.048