Written by: Choon Kiat William Chia

Concepts for Integrated Processing Platforms (IPP)

Extensive literature research was conducted to pre-screen the available concepts to accommodate the integrated production mechanism. The following are the concepts considered in this project:

- Concept 1: Re-purposing of existing oil and gas (O&G) platforms

- Concept 2: Hydrogen wind turbines

- Concept 3: New-build offshore platforms

To assess the viability of each concept, a decision matrix was created based on the factors listed in Table 1. For every factor considered, a relative score from a range of one (worst) to three (best) was assigned to each concept. Considering the relative weighting, the concept with the highest sum of score would be selected. Operational flexibility refers to the ability of the concept to synergise with other potential developments in offshore energy such as storage and transportation of the energy produced or even carbon capture and storage (CCS). On the other hand, technical complexity refers to how easy it is to construct or to modify the required structures to produce hydrogen.

Table 1: Factors considered while choosing the concept for IPP and their relative weightings.

Concept 1: Re-purposing of existing oil and gas (O&G) platforms

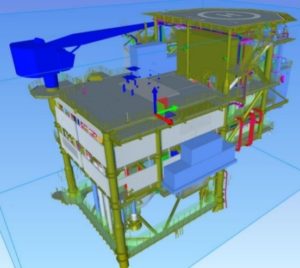

This concept involves the retrofitting of existing O&G platforms to host the equipment required to produce hydrogen. It is worth noting that this concept is the only one currently undergoing pilot project, the Q13A-A Production Platform in the Dutch North Sea (Offshore, 2019). As shown in Figure 1 (A) and Figure 1 (B), the platform was modified to host a containerised 1 MW electrolyser.

Figure 1 (A): Q13A-A production platform before the modification. (B): Proposed location for the containerised electrolyser on the platform (Energy, 2019).

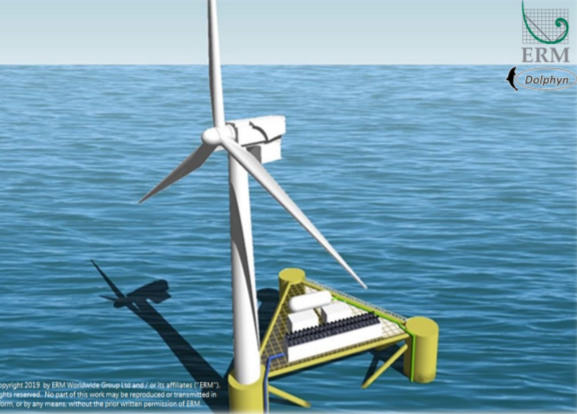

Concept 2: Hydrogen wind turbine

This concept involves the installation of electrolysers and associated equipment such as desalination unit within the wind turbine support structures (BEIS, 2019b). An example of this concept is the Dolphyn Hydrogen Project, a Front-End Engineering Design (FEED) conducted by Environmental Resource Management (ERM). The project investigated the feasibility of integrating a commercially operating semi-submersible type offshore wind turbine, Windfloat with the hydrogen production facilities. As shown in Figure 2, this was achieved by modification of the topside to accommodate the equipment required.

Figure 2: Artist impression of Dolphyn Hydrogen Platform (BEIS, 2019a).

Concept 3: New-build offshore platforms

This option involves the construction of purpose-built platform to accommodate electrolysers and other associated facilities to produce hydrogen (BEIS, 2019b). An example of this concept is the fixed jacket structure currently under development by Tractebel Engineering GmBH. As shown in Figure 3, the aforementioned platform would be equipped with a 400 MW electrolysis capacity.

Figure 3: Proposed hydrogen producing platform by Tractebel (Durakovic, 2019).

Chosen Concept for IPP

Based on the factors established previously, Table 2 shows that New-build offshore platform (Concept 3) had the highest score and hence was the selected concept for this project. The detailed reasons for each of the score assigned was explained below.

Table 2: Weighted decision matrix for selection of concept for IPP.

For the first factor, Concept 3 scores the highest as it allows hydrogen to be produced at industrial scale as newly built platforms would not be constrained by lack of space. On the other hand, Concepts 1 & 2 suffer from lack of scale due to insufficient space on such non-dedicated platforms to host the hydrogen production facilities that have large footprints (Bulder et al., 2019).

For operational flexibility, Concept 3 is able to host all related equipment such as transformers, desalination and etc in one platform (Cholteeva, 2019). Both Concepts 1 & 3 can serve as offshore energy hubs that integrate OWF with existing O&G infrastructures or even future technologies such as CCS facilities. On the other hand, Concept 2 would require other supporting structures as standalone hydrogen WTs would not be able to take on such a similar multirole (BEIS, 2019b).

For technical complexity, Concept 3 is the least complex as it is newly built while Concept 1 is the most complicated as existing platform needs to be overhauled. For Concept 2, it suffers from complications related to the addition of weight due to hydrogen production mechanism that will affect its seakeeping characteristics (Bulder et al., 2019).

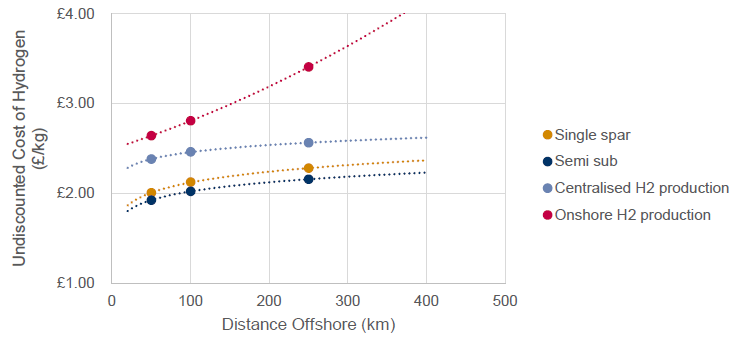

For cost, as seen from Figure 4, the cost of production for hydrogen WTs (Concept 2) in semi-submersible form is the lowest, followed by centralised production such as Concepts 1 & 3 while onshore production ranks last. Furthermore, Concept 1 is cheaper than Concept 3 as it modifies existing O&G platform as compared to the latter which is newly built (BEIS, 2019b). Once the concept for offshore hydrogen production had been chosen, the next stage would be to benchmark and select the appropriate offshore platform.

Figure 4: Estimated cost of hydrogen production for each production concept (BEIS, 2019a).

References

BEIS. (2019a). Dolphyn Hydrogen: Phase 1 – Final Report. Retrieved from https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/866375/Phase_1_-_ERM_-_Dolphyn.pdf

BEIS. (2019b). UKCS Energy Integration: Interim Findings. Retrieved from https://www.ogauthority.co.uk/news-publications/publications/2019/ukcs-energy-integration-interim-findings/

Bulder, B., Swamy, S. K., Warnaar, P., van Delft, Y., Bolman, R. B., NEC, F. B., . . . Naber–van der Aa, C. (2019). Innovations for Port of Den Helder Infrastructure following offshore wind developments.

Cholteeva, Y. (2019). Tractebek unveil new offshore hydrogen platform. Retrieved from https://www.power-technology.com/news/company-news/tractebel-hydrogen-wind-offshore/

Durakovic, A. (2019). Tractebel unveils hydrogen-producing offshore platform. Retrieved from https://www.offshorewind.biz/2019/10/02/tractebel-unveils-hydrogen-producing-offshore-platform/

Energy, N. (2019). PosHYdon Pilot. Retrieved from https://www.ogauthority.co.uk/media/6220/ogauthoritysharepointcom-ssl-davwwwroot-sites-ecm-tbw3-documents-files-exchange-malcolm-workshop-slides-301019-neptune.pdf

Offshore. (2019). Dutch platform chosen for hydrogen power plant. Offshore. Retrieved from https://www.offshore-mag.com/production/article/14036065/dutch-platform-chosen-for-hydrogen-power-plant