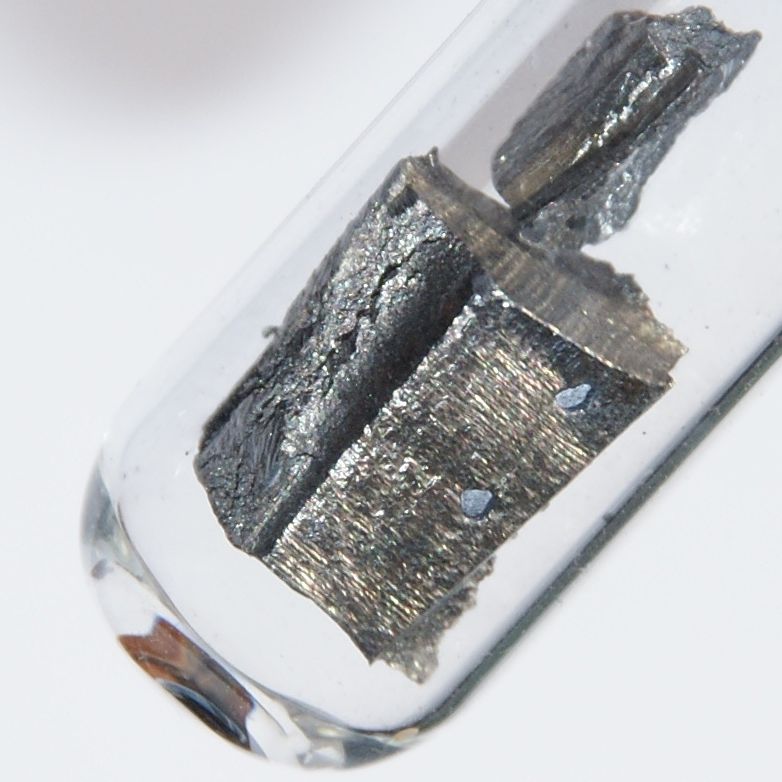

Determining the quantity of rare earth elements (REE) used in an electric vehicle battery is crucial for quantifying the amount of REE that will be needed for a transition phase from petrol/diesel cars to electric vehicles for Great Britain. REE are formerly known as a group of 17 elements, of which, each have their own individual physical and chemical characteristics, therefore can be used in wide variation of applications. REE are best known for their application in clean energy technologies such as wind turbines, electric motors, catalysts and solar panels due to strong permanent magnetic properties.

Rare Earth Elements get their name from being present only in few countries across the globe, and the countries that they are found in are in very scarce quantities. Rare earth deposits take longer to find because they as concentrated in areas as other elements. Understanding that large-scale extraction and use of REE are fundamental for an EV transition to take place, as well as increasing the installed capacity of renewable technologies highlights the importance of REE.

Rare Earth Elements get their name from being present only in few countries across the globe, and the countries that they are found in are in very scarce quantities. Rare earth deposits take longer to find because they as concentrated in areas as other elements. Understanding that large-scale extraction and use of REE are fundamental for an EV transition to take place, as well as increasing the installed capacity of renewable technologies highlights the importance of REE.

Application and Methodology

Mainly two REE's are used in electric vehicles; Neodymium (Nd) and Dysprosium (Dy). Neodymium is used in permanent magnet motors, often termed as neodymium iron boron magnets. Dysprosium is also used in motors but in minimal amount relative to neodymium.The average quantity of Nd is 200 grams whereas for Dy is 30grams(1). These values are average values taken from a study and subjective to change in coming future depending upon the availability of rare earth elements. The values were first converted into kg The respective values were multiplied by the vehicel sales rate for each year and from 2016 to 2050 to get the final amount of REE in tons required for Electric Vehicles sold in the UK within this time. The final value was converted from kg into tonnes to get the final amount of REE.

Mainly two REE's are used in electric vehicles; Neodymium (Nd) and Dysprosium (Dy). Neodymium is used in permanent magnet motors, often termed as neodymium iron boron magnets. Dysprosium is also used in motors but in minimal amount relative to neodymium.The average quantity of Nd is 200 grams whereas for Dy is 30grams(1). These values are average values taken from a study and subjective to change in coming future depending upon the availability of rare earth elements. The values were first converted into kg The respective values were multiplied by the vehicel sales rate for each year and from 2016 to 2050 to get the final amount of REE in tons required for Electric Vehicles sold in the UK within this time. The final value was converted from kg into tonnes to get the final amount of REE.

For Neodymium (kg) = 0.2 * Vehicle Sales Rate for each year.

The values were calculated from 2001 till 2050 and then the total amount was added to get the final value.

For Dysprosium (kg) = 0.03 * Vehicle Sales Rate for each year.

The values were calculated from 2001 till 2050 and then the total amount was added to get the final value.

The values were calculated from 2001 till 2050 and then the total amount was added to get the final value.

For Dysprosium (kg) = 0.03 * Vehicle Sales Rate for each year.

The values were calculated from 2001 till 2050 and then the total amount was added to get the final value.

Results

Through this modelling technique the final results for REE consumption up to and including 2050 for each scenario is calculated. Below the results for the Business as Usual scenario, the Conservative scenario and the Aggressive scenario. For the results for the other 6 scenarios, please see our results page

Neodymium

Dysprosium

Through this modelling technique the final results for REE consumption up to and including 2050 for each scenario is calculated. Below the results for the Business as Usual scenario, the Conservative scenario and the Aggressive scenario. For the results for the other 6 scenarios, please see our results page

Neodymium

- Business as Usual = 260 tonnes

- Intermediate = 1,178 tonnes

- Aggressive = 11,347 tonnes

Dysprosium

- Business as Usual = 39 tonnes

- Intermediate = 176 tonnes

- Aggressive = 1,782 tonnes

Conclusion

It is certain that the demand for neodymium and dysprosium is going to increase in future due to not only clean energy technologies but also Electric Vehicles. Great Britain and Europe little to virtually no natural deposits of rare earth elements, therefore it will become essential to have strategy in place for them to be recycled, or to continue development and research of electric batteries that do no contain rare earth elements. By 2018, only 1% of the REE are recycled. However, the European Commission have planned to recycle critical raw materials including REE to 70% in 2030(2). In recent years some of the automobile companies have replaced permanent magnet motors with induction motors(3). The question still remains in place; is it sustainable to have an electric vehicle transition at a global scale if environmental-friendly extraction and recycling processes are not implemented?

It is certain that the demand for neodymium and dysprosium is going to increase in future due to not only clean energy technologies but also Electric Vehicles. Great Britain and Europe little to virtually no natural deposits of rare earth elements, therefore it will become essential to have strategy in place for them to be recycled, or to continue development and research of electric batteries that do no contain rare earth elements. By 2018, only 1% of the REE are recycled. However, the European Commission have planned to recycle critical raw materials including REE to 70% in 2030(2). In recent years some of the automobile companies have replaced permanent magnet motors with induction motors(3). The question still remains in place; is it sustainable to have an electric vehicle transition at a global scale if environmental-friendly extraction and recycling processes are not implemented?

REFERENCES