Attenuator (Pelamis - Pelamis Wave Power)

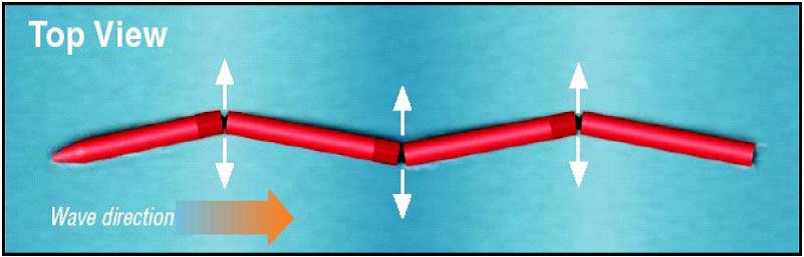

Ocean Power Delivery is developing a freely

floating hinged contour device. The device looks like a snake, floating on the

ocean surface. The device consists of 4 tubular sections, connected by 3 hinges.

The 4 sections move relative to each other and the hinges convert this motion

by means of a digitally controlled hydraulic power conversion system. The total

device length is 150m, with a tube diameter of 4.63m. A full-scale

pre-production prototype has been built and is currently

undergoing sea-trials off the coast of Scotland.

Structural Elements

The structure is a steel structure that can be built locally using standard construction techniques available at most shipyards. The device structure has been designed using standard offshore construction principles, and a leading offshore technology consulting firm independently verified the design.

Power Take Off

Each hinge of the device contains its own hydraulic power take off. Each power take off has a total of 3 hydraulic rams, which convert the motions into hydraulic pressure. Using accumulators and two 125kW generator sets, the hydraulic power is generating electricity. The hinges and power conversion mechanism have undergone full scale testing on a test-rig and have been integrated into the full-scale device. The hydraulic systems use biodegradable hydraulic fluids, which complies with the German ‘Blue Angel’ Environmental standard.

Structural Elements

The structure is a steel structure that can be built locally using standard construction techniques available at most shipyards. The device structure has been designed using standard offshore construction principles, and a leading offshore technology consulting firm independently verified the design.

Power Take Off

Each hinge of the device contains its own hydraulic power take off. Each power take off has a total of 3 hydraulic rams, which convert the motions into hydraulic pressure. Using accumulators and two 125kW generator sets, the hydraulic power is generating electricity. The hinges and power conversion mechanism have undergone full scale testing on a test-rig and have been integrated into the full-scale device. The hydraulic systems use biodegradable hydraulic fluids, which complies with the German ‘Blue Angel’ Environmental standard.

|

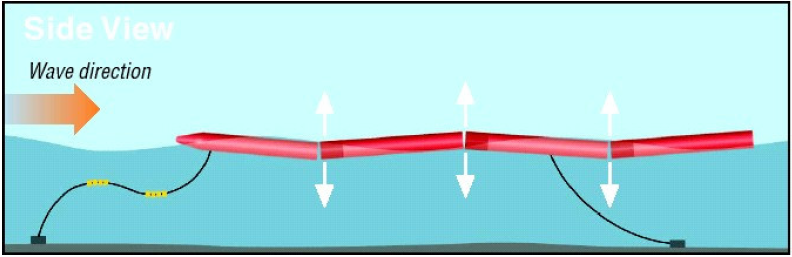

Mooring

The mooring consists of a 3-point slack-mooring configuration. The mooring allows the device to turn into wave direction within its mooring constraints. The mooring and survivability of the system has been simulated theoretically and tested in wave tanks. While the mooring is probably the least mature element in the overall system and will need to be looked at closely and adapted to the specific site requirements, it does not raise any concerns. The mooring and survivability has been independently analysed and verified by one of the leading offshore technology consultancy firms and is designed to withstand the 100-year storm wave. |

Grid Connection

The device features a frequency converter and an on-board step-up transformer. As such, it is able to completely synchronize with the wave farm transmission voltage. A flexible riser cable connects the surface device to a junction box sitting on the ocean floor.

Installation

The device is designed with quick deployment and recovery in mind. The power and three mooring connections can be quickly disconnected from a tug, the devices nose attached to a special harness and towing can begin. This approach requires a minimal amount of time spent offshore and will reduce the weather windows required to deploy or recover the device. The slender and long steel structure, will allow for a simple towing-operation using a single handler tug.

Performance

The device is able to rapidly tune to the incident wave climate using a digitally controlled hydraulic system and detune to over-sized waves. A large amount of effort has gone into optimizing the devices tuning and associated efficiency. The hydraulic power conversion train has an average efficiency of 80% and future versions will likely show improvements in conversion efficiencies and the capacity factor is of 40%.

Survivability

The Pelamis has excellent survivability characteristics. Being a relatively narrow device, which will point into the wave and is able to completely de-adjust to large waves, it will always minimize loads on its mooring system. The power take off and control subsystems have been designed with many redundancies in place to minimize reactive maintenance such as the required intervention after a storm. The estimated life duration of this device is 15 years.

Operation & Maintenance

The device is designed to be quickly disconnected from its mooring and towed into a nearby port for maintenance overhauls. Many subsystems, such as power modules, are designed in such a way that they can be lifted out with a crane and replaced with a tested subsystem. Remote diagnostic capability, extensive instrumentation and a high level of redundancy will minimize the physical intervention requirements and will allow O&M activities to be carried out during suitable weather windows.

Company Viability

Ocean Power Delivery has attracted a total of $2.5million pounds (US$ 5 Million) from UK government sources and has received over $6.0 million pounds (US$ 12 Million) in private equity investments from a number of large European venture capital firms. The company has demonstrated technical capability by taking this device from concept to full-scale using a rigorous approach of eliminating and testing at the appropriate scale.

Local Manufacturing

Most of the structural elements for a prototype can be manufactured in a local construction yard. Depending on the volume, most of the electrical and hydraulic machine elements can also be sourced from US sources.

The device features a frequency converter and an on-board step-up transformer. As such, it is able to completely synchronize with the wave farm transmission voltage. A flexible riser cable connects the surface device to a junction box sitting on the ocean floor.

Installation

The device is designed with quick deployment and recovery in mind. The power and three mooring connections can be quickly disconnected from a tug, the devices nose attached to a special harness and towing can begin. This approach requires a minimal amount of time spent offshore and will reduce the weather windows required to deploy or recover the device. The slender and long steel structure, will allow for a simple towing-operation using a single handler tug.

Performance

The device is able to rapidly tune to the incident wave climate using a digitally controlled hydraulic system and detune to over-sized waves. A large amount of effort has gone into optimizing the devices tuning and associated efficiency. The hydraulic power conversion train has an average efficiency of 80% and future versions will likely show improvements in conversion efficiencies and the capacity factor is of 40%.

Survivability

The Pelamis has excellent survivability characteristics. Being a relatively narrow device, which will point into the wave and is able to completely de-adjust to large waves, it will always minimize loads on its mooring system. The power take off and control subsystems have been designed with many redundancies in place to minimize reactive maintenance such as the required intervention after a storm. The estimated life duration of this device is 15 years.

Operation & Maintenance

The device is designed to be quickly disconnected from its mooring and towed into a nearby port for maintenance overhauls. Many subsystems, such as power modules, are designed in such a way that they can be lifted out with a crane and replaced with a tested subsystem. Remote diagnostic capability, extensive instrumentation and a high level of redundancy will minimize the physical intervention requirements and will allow O&M activities to be carried out during suitable weather windows.

Company Viability

Ocean Power Delivery has attracted a total of $2.5million pounds (US$ 5 Million) from UK government sources and has received over $6.0 million pounds (US$ 12 Million) in private equity investments from a number of large European venture capital firms. The company has demonstrated technical capability by taking this device from concept to full-scale using a rigorous approach of eliminating and testing at the appropriate scale.

Local Manufacturing

Most of the structural elements for a prototype can be manufactured in a local construction yard. Depending on the volume, most of the electrical and hydraulic machine elements can also be sourced from US sources.