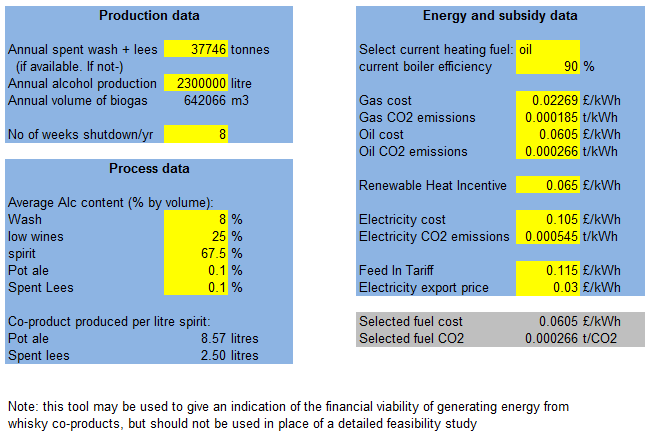

Primary Inputs

Information which is vital to the calculations the tool performs can be entered by the user on the Primary Inputs page. Once this page is completed, preliminary results are available on the Results page. The remaining five pages can be used to refine the preliminary results. A description of the sections which appear on the Primary Inputs page, and the key inputs they require, are given below.

Production Data

- Annual Pot Ale & Lees: If the number of tonnes of pot ale and spent lees available annually is known, it can be entered in the first input cell in this section. The section Process Data can then be ignored. If the number of tonnes is not known, the formula contained in this cell when the tool is opened should be left in place.

- Annual Alcohol Production: If the amount of pot ale and lees is not known, the volume of alcohol produced per year can be entered in the second input cell in this section instead. The tool then calculates the amount of liquid co-product available based on the process information (users will see the figure in the Annual Pot Ale and Lees cell change).

- Number of Weeks Shut-down/Year: Co-products may not be produced at an even rate throughout the year. The tool is able to take account of the number of weeks when the distillery is not operating, for example during holiday periods or maintenance. However it does not take account of smaller variations in production rate. The tool assumes that biogas is not produced (and no energy generated) when the distillery is not operating, and that production is evenly spread across the remaining weeks of the year.

Process Data

This section is only relevant if the amount of liquid co-products is not known. In this case, the amount of co-product is calculated from the volume of alcohol produced. This calculation is based on a mass balance equation which requires the percentage alcohol content by volume for each stage of the production process to be input. Typical values are included in each of the five input cells in this section. These can be checked and amended as necessary by the user. The section outputs the tonnes of liquid co-products produced per litre alcohol.

- Wash: Average percentage alcohol content of the wash after fermentation.

- Low Wines: Average percentage alcohol content of the distillate from the wash still (this value does not affect the total amount of liquid co-products or the results given by the tool. It only needs to be given accurately if the ratio of pot ale to spent lees is of interest to the user.)

- Spirit: Average percentage alcohol content of the distillate from the spirit still.

- Pot Ale: Average percentage alcohol content of pot ale remaining in the wash still after a distillation run is stopped.

- Spent Lees: average percentage alcohol content of spent lees remaining in the spirit still after a distillation run is stopped.

Energy and Subsidy Data

In this section the user should select the heating fuel currently used by their distillery, and input the efficiency of the distillery’s current boiler. The section also contains default values for fuel costs (in units of £ per kWh), subsidy rates and carbon dioxide emissions (in units of tonnes per kWh). These can be adjusted by the user if required.