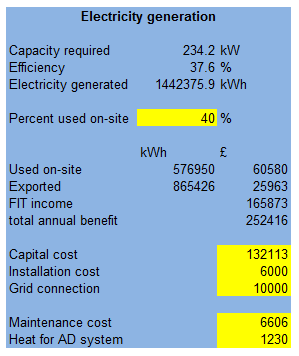

Electricity Generation

The tool’s Electricity Generation page calculates the electricity that could be produced from the biogas available.

- Capacity Required: It is assumed that a generator unit would be run at constant load throughout the year, with the exception of weeks where the distillery is shut down for holidays or maintenance. The capacity of the unit required is calculated from the volume of biogas available on this basis.

- Percent Used On-sire: It is assumed that electricity generated surplus to the distillery’s demand can be exported to the grid. If this is not the case, electricity generation is unlikely to be an economically attractive option for using the biogas produced. Assuming electricity can be exported, an important factor affecting the economic results is the percentage of the electricity generated which is used on-site to meet the distillery’s demand. The user may wish to use a software tool such as Merit (as was used in this project for the case study distillery) to obtain this data.

The tool provides an estimate of the capital cost of a generator unit based on information collected from suppliers and the capacity required. Information obtained on grid connection costs varied greatly, and it has been separated out from the estimate for other installation costs. These costs can be changed by the user if specific estimates have been obtained from equipment suppliers or contractors.

Maintenance costs are again assumed to be 5% of capital costs. As no heat is produced in this generation option, it is assumed that the AD system heat demand calculated on the Biogas production page must be met by the distillery’s current boiler. The cost of the additional fuel required is therefore included in the Electricity Generation Annual Cost displayed on the results page.