BREAL

|

Scenario 4 represented if the island was to aim to be net energy positive – where all electricity consumed on the island is also generated there. The constant population demand profile for scenario 1 was used. The grid connection now blocks any imports from the mainland, but still allows for exports to be sold. After several different methods and technologies were tried, it was found that the most cost-effective way to meet the carbon reduction targets and provide enough energy to meet demands was to implement anaerobic digestion and biogas. This has been supplemented with 1.5MW of PV and 2.9MWh of Tesla Lithium-Ion batteries, as used in the other scenarios. The three second-hand Vestas turbines, have also been replaced by a single, larger 800kW turbine.

|

This scenario was originally modelled with only additional solar and wind generation with storage. However, it was found that this was not feasible due to the stochastic nature of the renewable sources. There just needed to be a few days in a row without much wind or sun, and the battery bank would drain rapidly leading to unmet load. It was also modelled using the electrolysis process and fuel cells, but this was found to be less economically viable, results from this simulation can be found here. Implementing anaerobic digestion with a biogas turbine was thus found to be the most cost-effective way to ensure security of supply in an energy system where the demand is met from solely renewable sources. In this case the produced biogas from the digester would have to be stored until required, then fed through the turbine to produce electricity when the battery bank was starting to drain in times of low renewables output.

|

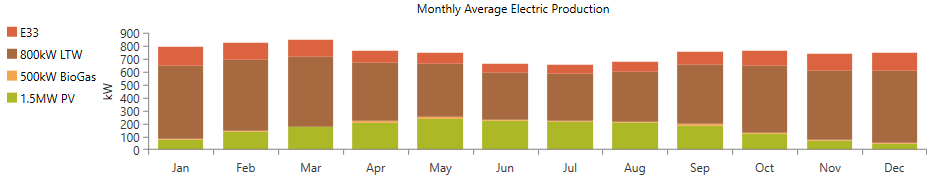

Replacing the three older wind turbines, with one single turbine of a similar total rated capacity, greatly increased the power output from wind on the island. This is maybe partially due to the higher hub height of the larger turbine. The significance of the power output from the 800kW turbine is shown in the monthly electrical production chart, where the consistently high output throughout the year is made clear. The large wind turbine meets 63% of the islands energy requirements across the year, compared to the three Vestas turbines meeting 45% in scenario 1. The large 1.5MW PV installation helps make up the demand in summer months when wind output drops, contributing to 21.4% of the islands total energy produced. As the biogas is used for back-up in this scenario it only makes up 1.1%.

|

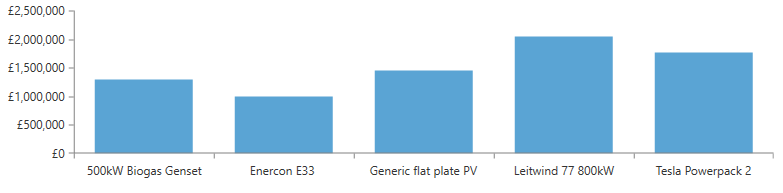

The new wind turbine makes up the largest cost for this scenario, at over £2million when taking all costs into account. However, this would likely be worth the investment, as shown from the potential energy output. The capital cost of the 800kW turbine was estimated to be £1.2 million, based on information from ‘renewables first’ of a similar sized turbine costing £1.4 million [17]. This figure was reduced due to it including infrastructure costs such as access roads, that are already in place for the Vestas turbines (this is assuming that the new turbine would be installed at the same site). The cost of implementing anaeorobic digestion with a biogas turbine was assumed to be around £2,500 per installed kW of the biogas turbine - taking all infrastructure investment into account. This figure was estimated from using the 'BioGC' tool [18]. The costing for the PV and storage intallations was the same as previously described in the results for Scenario 1.

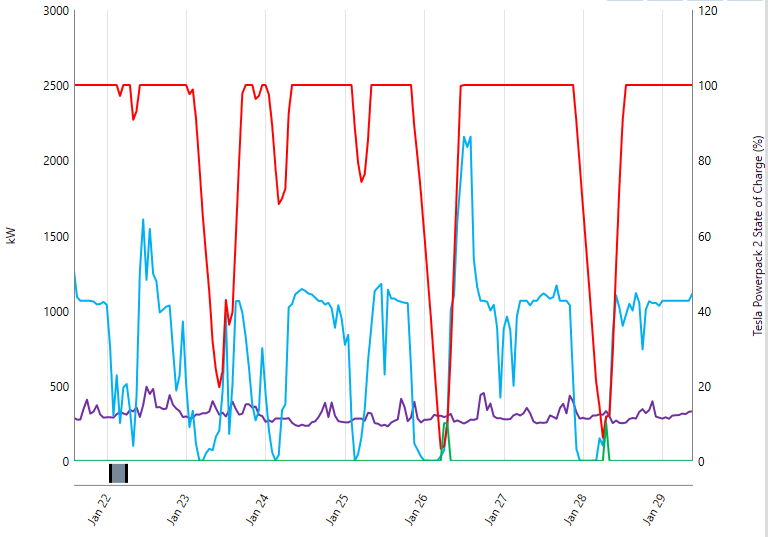

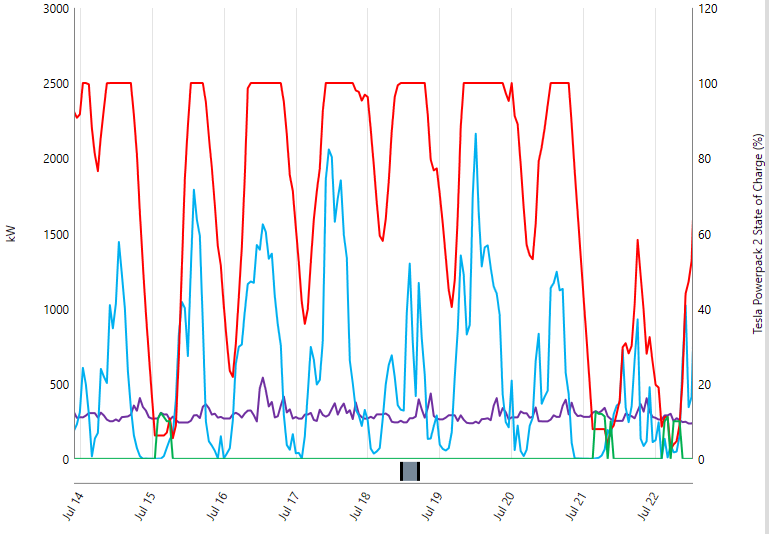

The operation of the system for a summer and winter week is shown above. The system functions similarly to the other scenarios, with excess renewables charging the batteries. Except in this scenario the biogas turbine is used for back-up generation when the load cannot be met from the renewables output or batteries, instead of grid purchases. This would require an effective control system to be implemented in order to function correctly. When the stored charge in the battery bank went below a certain value, the biogas turbine would be switched on, burning stored gas previously produced in the digester to create electricity. Heat from the biogas turbine could also be used to in a CHP scheme to heat nearby houses.

One issue with this potential scenario arises from the high amount of excess electricity created from the substantial amount of installed renewables generation – this is shown in the graph below. Here, the excess energy would all be exported to the grid to generate income. As can be see in the graph, the exported electricity is consistently above the 1MW export limit. This scenario would require a cable with an export limit of slightly over 2MW to be functional. This is feasible, as the island of Cumbrae has a gird connection with a 5MW export limit. However, the island may struggle to get a new cable installed if they were to no longer be buying energy from the mainland. Thus, this represents a potential large hurdle for if the island was to be net energy positive.

Another potential issue with this scenario is that the island has previously done a feasibility study into anaerobic digestion and found it would not be economically feasible, due to a lack of available cow manure. However, it is believed this study did not consider other potential feedstocks for the digester, such as food waste, human sewage and seaweed. As the biogas would primarily be stored and used for back-up generation, a consistently high power output would not be required, which may have been assumed for the previous investigation.

Create a free web site with Weebly