BREAL

Following UK`s strategy for 2050 of decarbonising the heating, all of the scenarios for 2030 will be modelled assuming that all suitable domestic properties on the island will be heated with heat pumps.

Why heat pumps:

Why heat pumps:

|

1. Decarbonisation of heat

Depending on the unit and outdoor temperature, 50-80% of the energy delivered by heat pump, comes from renewable sources (solar). As most of the leading manufacturer units for domestic properties achieve SCOP of 3.5 or higher, carbon emissions comparing to direct electric heating will be reduced at least 3.5 times, down to 0.10 CO2/kWh. |

CO2 emissions for heating sources used on the island:

|

2. Running costs reduction

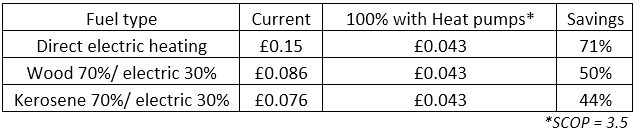

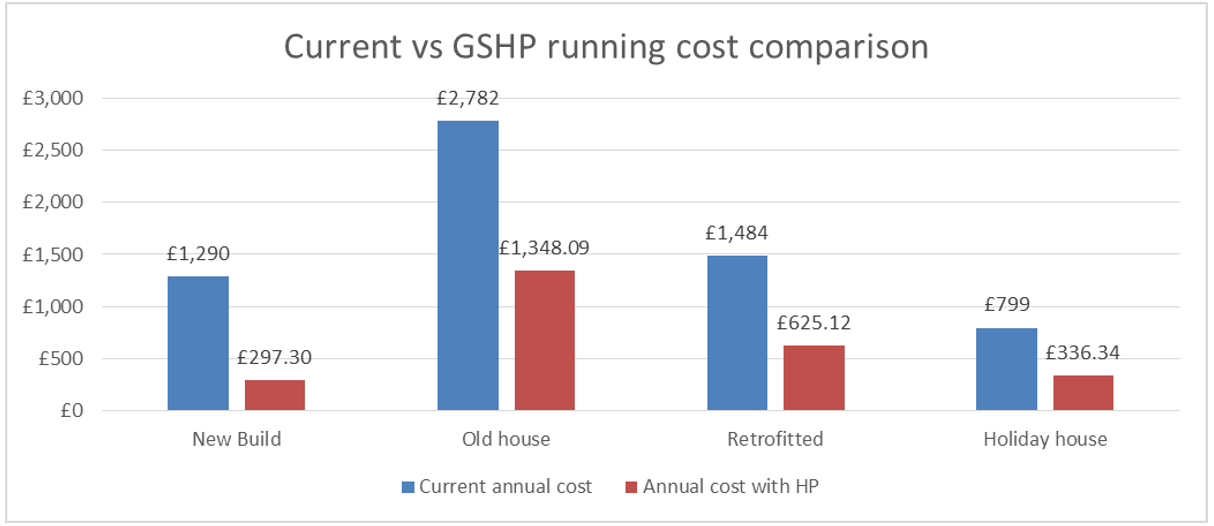

Heat pumps will significantly reduce the running costs for all new builds which are heated directly with electricity and for the properties using biomass/electricity or kerosene/electricity to supply heat. A high level cost comparison of heating types currently used on the island with heat pumps is shown below. Full details of the calculation and results - showing tables and graphs for each house and heat pump type- follow underneath.

Heat pumps will significantly reduce the running costs for all new builds which are heated directly with electricity and for the properties using biomass/electricity or kerosene/electricity to supply heat. A high level cost comparison of heating types currently used on the island with heat pumps is shown below. Full details of the calculation and results - showing tables and graphs for each house and heat pump type- follow underneath.

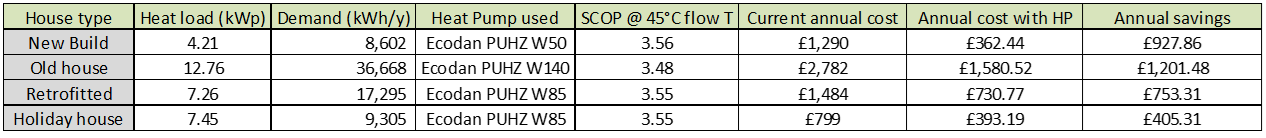

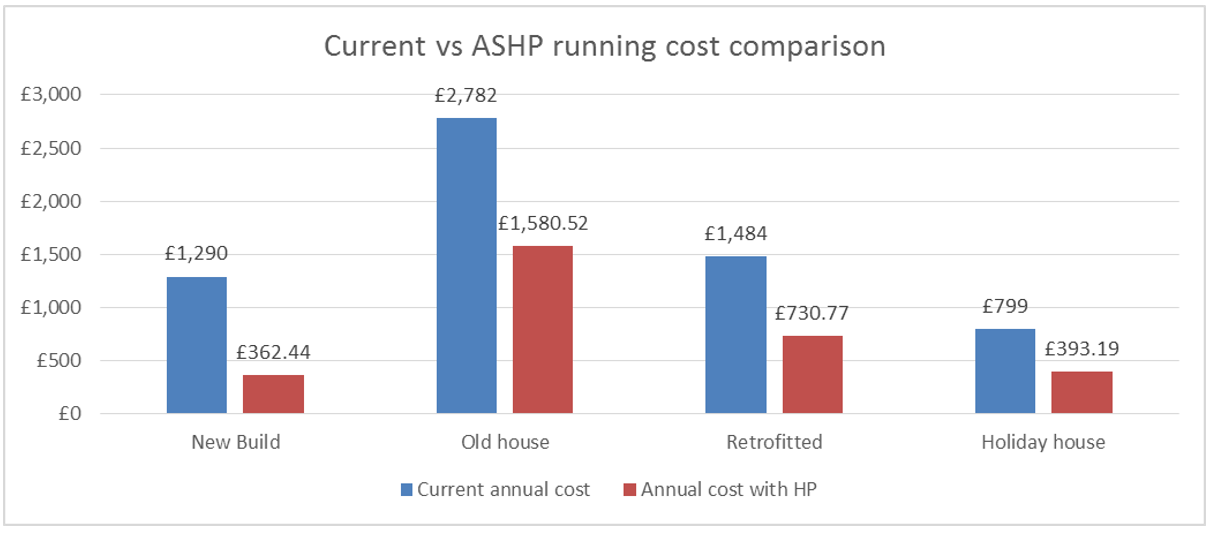

Air Source Heat pumps:

Annual savings for each house type due to the lower running cost from Air Source Heat pumps.

“Old house” peak and annual heating load is reduced due to external wall insulation and window replacement. Fuel prices as given in the table above. Annual savings does not incorporate mandatory annual servicing which would cost around £300. “Holiday house” significantly lower kWh is due to these properties not being occupied for the whole year.

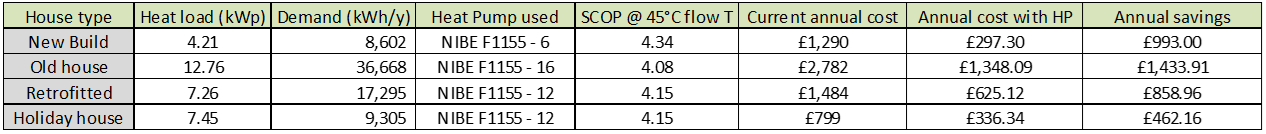

Ground Heat Source:

Annual savings for each house type due to the lower running cost from Ground Source Heat pumps.

“Old house” peak and annual heating load is reduced due to external wall insulation and window replacement. Fuel prices as given in the table above. Annual savings does not incorporate mandatory annual servicing which would cost around £300. “Holiday house” significantly lower kWh is due to these properties not being occupied for the whole year.

As can be seen in the graphs above, the implementation of heat pumps (either ground or air source) to meet heating demand will substantially reduce running costs for each house type present on the island. A reduction of at least 50% in heating costs is present for each house type

3. Income generation

Further financial benefits will result from the implementation of heat pumps on the island through the available income through the Renewable Heat Incentive (RHI) scheme. Calculations of the potential income for each house type, for both ground and air source heat pumps, are shown below.

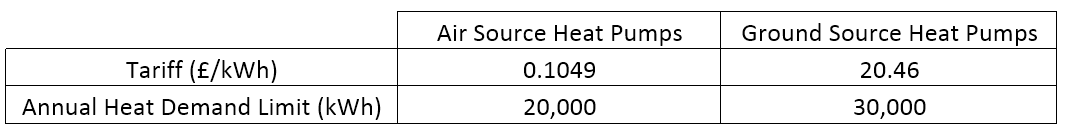

Current (April 2018 – June 2018) domestic RHI tariffs and demand limits [14].

Further financial benefits will result from the implementation of heat pumps on the island through the available income through the Renewable Heat Incentive (RHI) scheme. Calculations of the potential income for each house type, for both ground and air source heat pumps, are shown below.

Current (April 2018 – June 2018) domestic RHI tariffs and demand limits [14].

Formula used for RHI income calculation (SPF is replaced by SCOP value):

SCOP value depends from design flow temperature and selected heat pump.

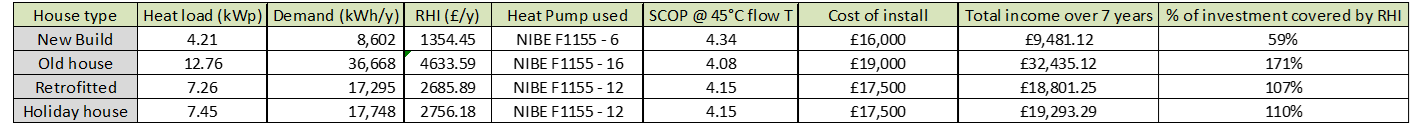

“Old house” peak and annual heating load is reduced due to external wall insulation and window replacement. SCOP value depends from design flow temperature and selected heat pump. MCS product database [8]. “Holiday house” significantly lower kWh is due to these properties not being occupied for the whole year, but for RHI payment calculations total annual figure is used, because RHI payments (unless heat meter installed) is based on EPC demand figures, therefore ignoring actual usage.

“Old house” peak and annual heating load is reduced due to external wall insulation and window replacement. SCOP value depends from design flow temperature and selected heat pump. MCS product database [8]. “Holiday house” significantly lower kWh is due to these properties not being occupied for the whole year, but for RHI payment calculations total annual figure is used, because RHI payments (unless heat meter installed) is based on EPC demand figures, therefore ignoring actual usage.

Potential income for each house type if Air source heat pump would be installed.

Potential income for each house type if Ground source heat pump would be installed.

It is clear that both – air source and ground source heat pump technologies are currently significantly subsidised by the UK government to promote the decarbonisation of heating. As can be seen in both tables above, the capital investment needed for this kind of upgrade is covered in full by government subsidies (except for smaller size installations). This allows (if needed funds or access to inexpensive loans is available) the end user to benefit from increased comfort (due to smart controls and no need for fuel sourcing) and reduced running costs up to 20 years (expected life span of heat pumps). Additionally, the majority of energy required for heating will come from a renewable source - as 70% of electrical generation on the island is from renewables. As RHI scheme faces regular degression (next one occurring on June 2018) it is important to consider this kind of upgrade in near future, to not miss out on available subsidies.

4. Thermal Storage

Another benefit from electrifying heat with heat pumps is the available thermal storage. Most modern heat pumps are now inverter driven, meaning – due to high modulation capabilities, the need for a 200-300l buffer tanks are eliminated and all that is needed is 20-40l tank. This is in order to hold enough energy to perform a defrosting cycle (ASHP). However a domestic hot water tank of 150-300l is still installed with every heat pump.

There are high temperature heat pumps available, which can produce temperatures up to 80°C, but for this feasibility study, the focus is on selected Mitsubishi ASHP and NIBE GSHP – max temperature of 55°C.

Case study:

For an immersion heater to raise the temperature from 55°C (max for HP) to 75°C, 5.73 kWh of energy needs to be supplied (An equivalent Li-on battery costs approximately £6000). That would represent available storage capacity available per property. For all 66 properties on the island it results in 378 kWh (1248 kWh for 10°C to 75°C temperature raise) of storage capacity. In future, if smart grid features would be implemented on the island (current transformers detecting export and switching on the immersions automatically), it would allow to minimise the wind exports by charging the hot water tanks when generation exceeds demand.

Another benefit from electrifying heat with heat pumps is the available thermal storage. Most modern heat pumps are now inverter driven, meaning – due to high modulation capabilities, the need for a 200-300l buffer tanks are eliminated and all that is needed is 20-40l tank. This is in order to hold enough energy to perform a defrosting cycle (ASHP). However a domestic hot water tank of 150-300l is still installed with every heat pump.

There are high temperature heat pumps available, which can produce temperatures up to 80°C, but for this feasibility study, the focus is on selected Mitsubishi ASHP and NIBE GSHP – max temperature of 55°C.

Case study:

- 250 litre DHW tank

- Storage temperature 55°C

- Legionella risk management proposes – once a week till 60°C using immersion heater.

For an immersion heater to raise the temperature from 55°C (max for HP) to 75°C, 5.73 kWh of energy needs to be supplied (An equivalent Li-on battery costs approximately £6000). That would represent available storage capacity available per property. For all 66 properties on the island it results in 378 kWh (1248 kWh for 10°C to 75°C temperature raise) of storage capacity. In future, if smart grid features would be implemented on the island (current transformers detecting export and switching on the immersions automatically), it would allow to minimise the wind exports by charging the hot water tanks when generation exceeds demand.

Due to the benefits described above, air source heat pumps have been implemented in all 2030 scenarios, with the resultant changes to the electric demand applied to each 2030 electric demand profile.

Create a free web site with Weebly