BREAL

|

An alternative energy solution to scenario 4 was modelled using electrolysis and fuel cells. This was because the island community had expressed a strong interest in this technology and if it was viable. Our feasibility study for fuel cells determined it would not be economical for the island to currently implement, but that it could be a solution if the island was to seek a higher degree of energy autonomy. An alternative to scenario 4 was therefore modelled with fuel cells, to compare with using biogas.

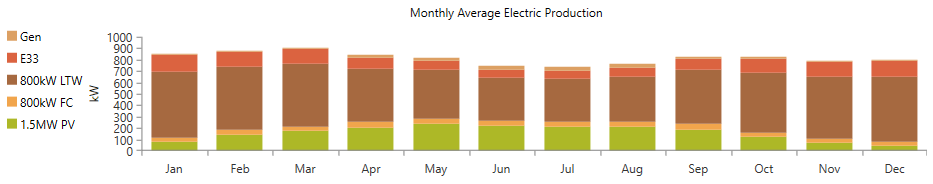

The same new PV installation and wind turbine from scenario 4 were added to the current energy system, but this time with an electrolyser, hydrogen tank and fuel cell instead of the Li-Ion batteries and biogas turbine. The electrolysis process for this scenario acts as storage and back-up generation. |

As in scenario 4, the system was modelled with the grid connection removed, and excess generated electricity being assumed as grid exports. The electrolyser, fuel cell and hydrogen tank were sized as described in the fuel cell feasibility study – in order to maximise the potential hydrogen yield from excess generation. The diesel generator was not removed in this scenario, as it was still required for back-up, when the fuel cell could not meet the load.

|

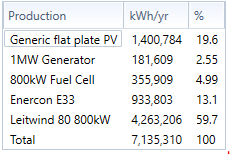

As evident in the electrical production table and graphs, the fuel cell was only able to provide around 5% of the islands total energy demand, despite the large amounts of surplus renewables generation available for electrolysis. The fuel cell was also unable to completely replace the diesel generator for back-up, with is being required to generate around 182,000 kWh over the course of the year. This would be very expensive for the island in terms of fuel, and also release a substantial amount of unwanted emissions.

|

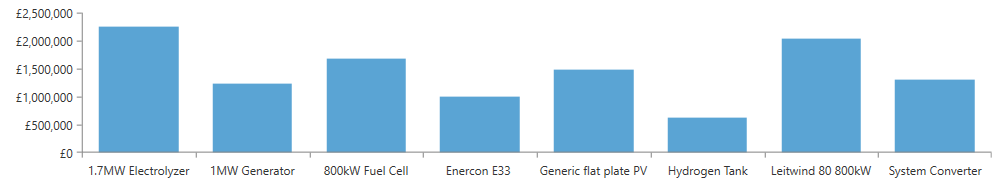

The costs for this energy system are shown above. Due to the immaturity of the technology the electrolyser and fuel cell are the largest expense. The capital investment costs for these items were based on research from the American national renewable energy laboratory. They estimated that fuel cell stacks currently cost around £3000 per kW, and electrolysers around £700 per kW [19].

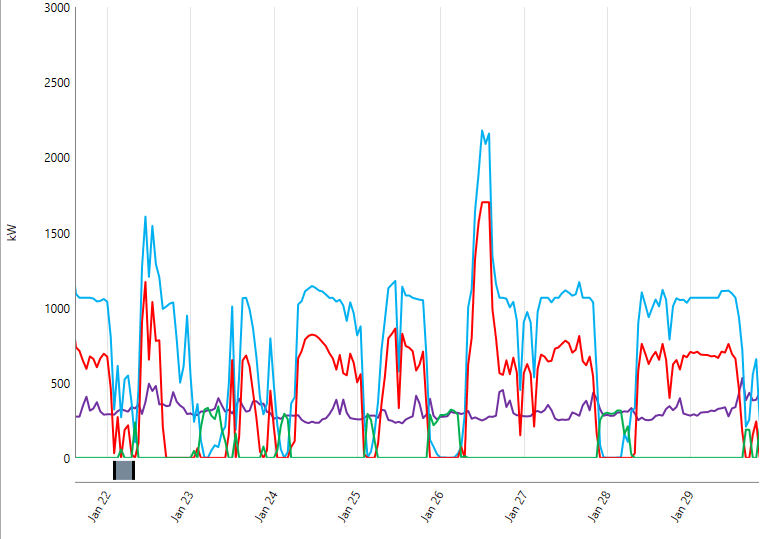

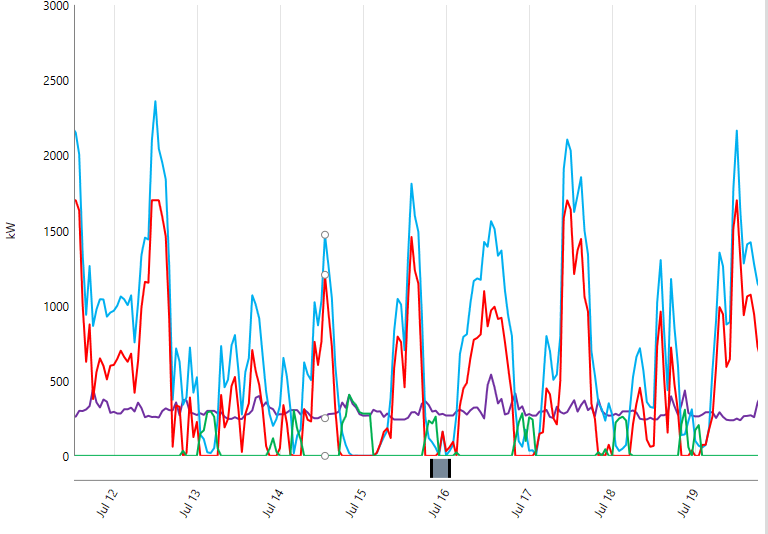

The operation of this system for a summer and winter week is shown below. Any excess generation from the renewables is sent through the electrolyser to generate hydrogen which is stored in the tank. When the renewables output cannot meet the demand, the hydrogen is used to generate electricity in the fuel cell.

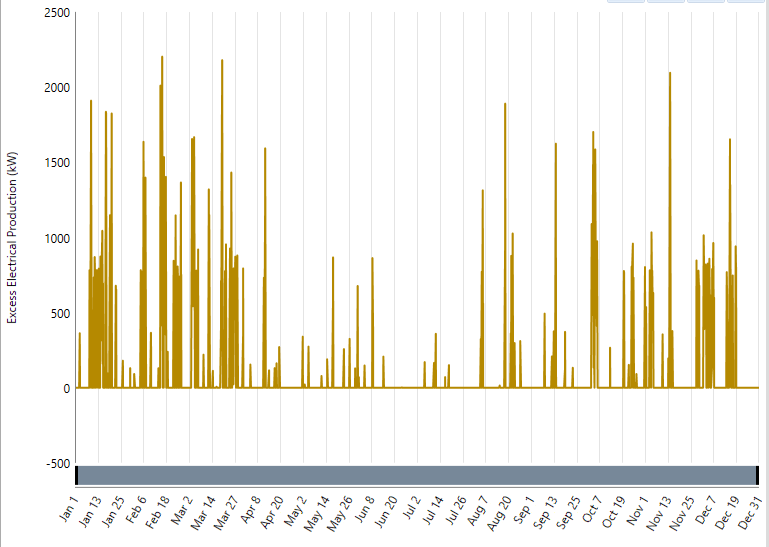

The excess electrical production that would be exported to the grid is shown above. Despite there being less excess generation overall than in scenario 4 with biogas, the peak amounts of excess production are still well above the current export limit. Therefore fuel cells would not be able to be implemented in this case without a new subsea cable being installed.

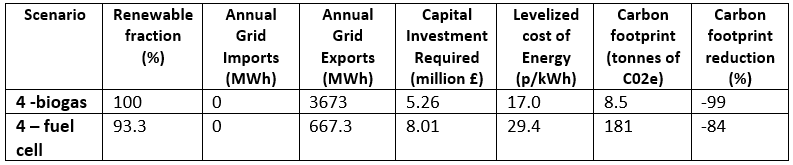

A comparison between scenario 4 modelled with fuel cells and scenario 4 modelled with bigoas is shown above. With fuel cells, the energy system is significantly more expensive, in terms of both the capital investment required and the levelized cost of energy. The carbon footprint is substantially higher with fuel cells, due to the reliance on the diesel generator for back-up generation. This also causes the scenario with fuel cells to have a lower renewable fraction of 93% compared to 100% with biogas. Despite the exports being signiciantly lower for the system with fuel cells, as shown above the peak value is still above the current export limit, so a new cable would still be required. It can therefore be deduced that implementing anaerobic digestion with biogas is currently the optimal method to meet the carbon reduction targets for scenario 4. It is cheaper than implementing fuel cells and produces less emissions due to not requiring the diesel generator for back-up. Electrolysis and fuel cells may be more economically viable in the future, when they have matured as a technology, with improved round trip efficiency and decreased costs.

Create a free web site with Weebly