WHY IS THERE DESIRE TO IMPROVE AUTONOMY?

This factory produces different penicillin products. The process of the penicillin is a batch process, in which a cut off of the process could result in the disposal of the entire final product. The interruption of that process could be as a consequence of a fault in the grid, causing a lack of electricity imports. An aim of this project is to avoid an interruption in the process of the pharmaceutical product because of an external failure.

In recent years, the factory has had some issues with the electricity imported from the grid. The worst moment was when a grid blackout interrupted the penicillin process in 2013. The consequence of this interruption was millions of pounds in losses. Besides the blackout issue, the necessity to balance the national grid electricity in the next years by the electrical companies in UK could cause enforced rota-disconnections to the factory.

Therefore, two of the main reasons why the factory wants to improve its autonomy are:

- Grid Blackouts

- Rota-disconnections

Grid blackout: is an unexpected fault in the grid that makes a factory off-grid for a period of time. In the case of the factory of GSK in Irvine, the blackout could produce an interruption of the process. The process in this factory is a batch process so if the process is cut off the final product must be thrown away. As a consequence of this disposal of the product, millions of pounds is lost.

Rota-disconnection: is a disconnection from the grid to the factory, with notice in advance from electrical companies. This disconnection can be mitigated more easily than blackouts.

Because of this uncertain future, the company has decided to build up its own production of energy in the site.

ON-SITE GENERATION

The on-site generation is based on different technologies:

- 2 Wind turbines of 2.5 MW each

- 2 Wind turbines of 2.5 MW each planned by the next years

- 1 Biogas plant of 1 MW that is feed by the waste products of the batch process

- 1 Biomass plant of 20 MW planned by 2018

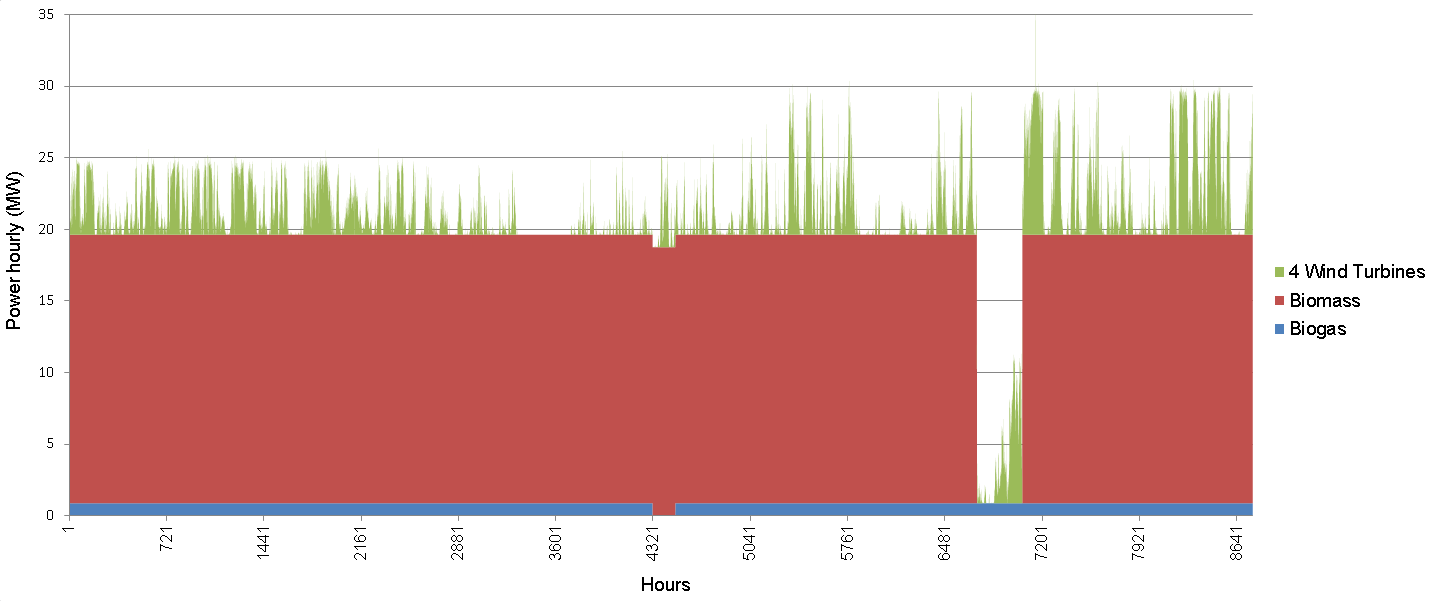

The modelling of the Biomass plant and the Biogas plant electricity generation has been supposed to be constant. A reduction in the output of the Biogas and Biomass plant has also been assumed because these plants are not going to work all year at full power. In the end the actual output we modelled was:

Biomass plant = 18.75 MW

Biogas plant = 872.48 kW

The accumulative power of all the on-site generation over a year is drawn in figure 1.

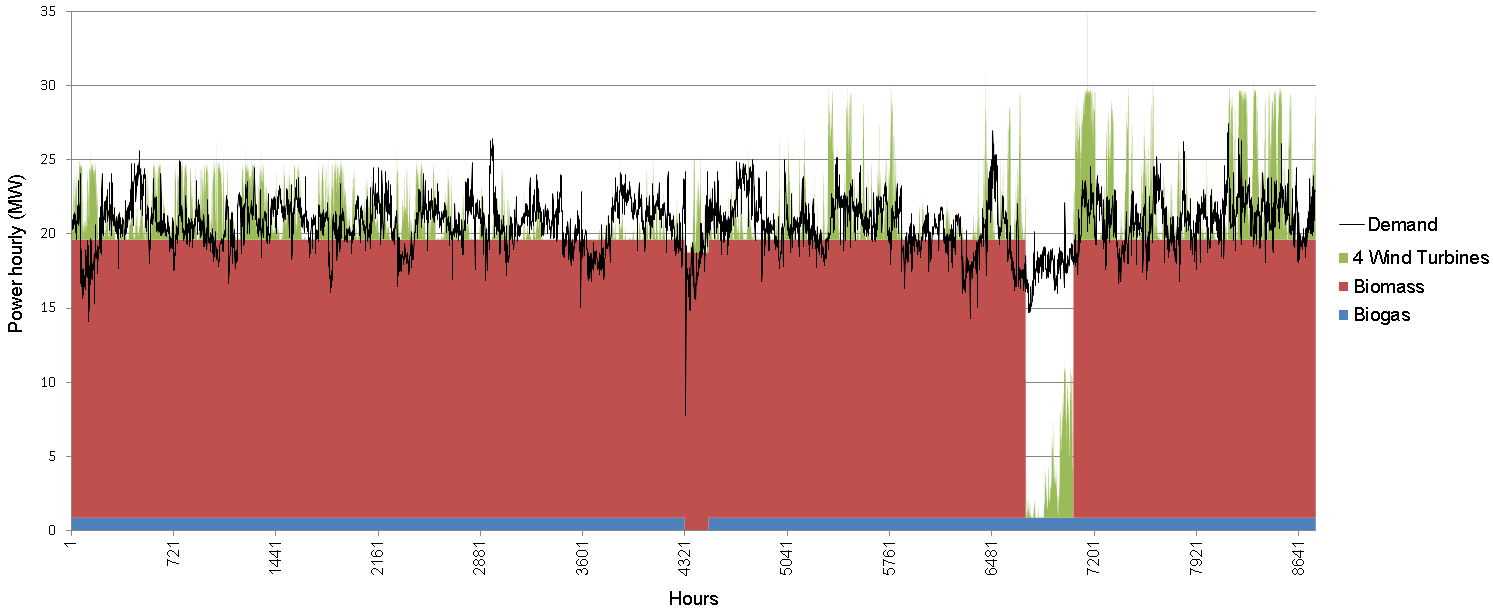

Figure 2 shows how the demand of the factory of GSK matches with the on-site generation.

The on-site generation increases the percentage of time when the factory is autonomous. Our study has been based on the improvement of this autonomy by implementing energy storage technologies.

Deficit and Surplus

The deficit is the gap between the on-site generation and the demand. That means when the generation in the site does not reach the demand. In this case the energy must be supplied by the energy storage technology or imported from the grid.

The surplus is the excess of the on-site generation relative to the demand. This surplus must be stored in order to use it afterwards, during a period of deficit. Not all the surplus can be stored due to the charging rate.

The three energy storage technologies studied for the GSK factory, due to its demand and on site generation, were:

- Electrochemical batteries

- Flow batteries

- Liquid air