Liquid Air Energy Storage

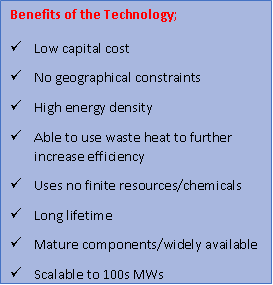

One of the possibilities for the GSK site is liquid air energy storage, which is a new technology that currently has one large pilot scheme in the south of England, created by a British company called ‘highview power storage’. One of the major benefits of this technology is that it uses multiple existing and well established processes from the turbo-machinery, power generation and industrial gas sectors, meaning that all the products being used all long lasting and very reliable. To put simply the technology is based on an air liquefier that produces liquid air by refrigerating ambient air to -196C. This air is then stored in unpressurised tanks and can then be drawn out and recombined with ambient temperatures which in turn causes a 700 fold expansion in volume, which is then put through a turbine (see diagram below for the process). Some of the advantages of the system are shown below.

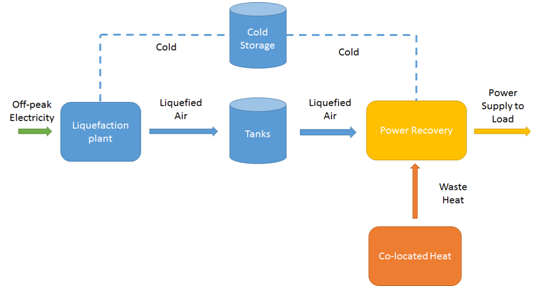

There are three main stages/processes for this technology; charging the system, storage and power recovery. Details of these processes are given below along with a diagram to show the basic layout of the system.

Stage 1. Charging the System – This system includes an air liquefier, which uses electrical energy to draw air from the ambient air. During this stage, air is cleaned and cooled to -196C so that it is able to liquefy. In this process, 700 unites of ambient air represents 1 litre of liquid air.

Stage 2. Energy Storage – The processed liquid air is stored in an insulated and low pressure tank, where it can be stored until needed. This is the major benefit of the technology as the tanks are widely available from storing liquid nitrogen for example, and can hold high capacities of energy at any one time.

Stage 3. Power Recovery – When power is required, liquid air can be drawn from the storage tanks and then pumped up to high pressure. Stored heat from the air liquefier can be used and applied through heat exchangers as well as exposure to ambient air temperatures. The high pressure has can then be drawn through a turbine to create electricity.

Cold recycle - At the 3rd stage, during the power recovery process, a portion of the liquid air which has been compressed to high pressure is stored in a high-grade cold store.

Thermal Store - The heat loss during the subcooling of ambient air to liquid air at stage 1 is stored in a Thermal Storage and then integrated at stage 3 (power recovery process) to raise the temperature of the high pressure liquid air which then produces a high-pressure gas, used to drive a turbine.

KEY FEATURES OF LAES

Scale: Highview has the capacity to design custom-made LAES ranging from MW output and 15MWh storage capacity to 50MW output and 200MWh of capacity and unlike pumped hydro or CAES, does not require caverns for storage.

Efficiency: LAES system has an efficiency of about 60% but the company is currently exploring the feasibility of increasing the efficiency to 70%.

Costs: The costs of LAES systems are synonymous with that of other storage systems and in contrast to batteries, it has a long lifetime which reduces intermittent replacement

Start-Up time: The technology uses

turbo-machinery during the charge and discharge process and has a response time

of about 2 minutes