Methodology/Geometry

The purpose of this study was to identify how variation of the following parameters would affect the power output of a turbine.

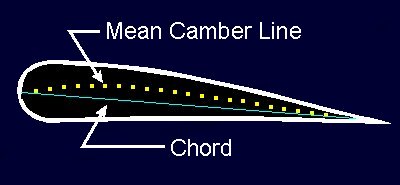

Blade Chord

- The distance from the front of the blade to the back.

http://www.petester.com/aeropics/mcline.gif

Chord Taper

- Variation in the chord from the root to the tip.

http://www.onemetre.net/Design/Downwash/Taper.gif

Blade Tip Radius

- The distance from the axis of rotation to the tip of the blade.

Blade Root Radius

- The distance from the axis of rotation to the root of the blade (where the blade meets the hub).

Blade Profile

- The cross sectional shape of the blade.

http://www.ae.illinois.edu/m-selig/ads/coord_database.html

Blade Pitch or Twist

- The angle at which the blade is set, relative to the inflow. If this is varied along the length of the blade it is said to be twisted.

Blade Surface Degradation

http://www.racerocks.com/racerock/energy/tidalenergy/april07fouling/fouling.htm

Single or Contra-Rotation

In order to evaluate how each of these parameters would influence power output it was first necessary to define some baseline turbine which would provide reasonable power values over sensible range of tidal velocities. After some initial investigations, the following turbine geometry was settled upon.Unless a parameter was that being investigated, it would be set to the corresponding value above.

Parameters |

Value |

Profile |

NREL S814 |

No of Blades |

5 |

Chord Length |

0.4m (uniform) |

Tip Radius |

4m |

Root Radius |

0.4m |

Pitch Distribution |

Twisted (Optimised for incident velocity of 2m/s) |

RPM |

25 |

Rotor |

Single |

Twist

Twist was calculated by determining the required pitch angle (β) at each node along the length of the span for a particular incident velocity to produce a desired angle of incidence (α).

For the baseline turbine, we took U(1-a) to be equal to 2m/s and negated a’ when calculating φ. As the maximum lift to drag ratio occurs at 7° for a clean blade and at 5° for a degraded blade, 6° was chosen as the target angle of incidence.

For the baseline turbine, we took U(1-a) to be equal to 2m/s and negated a’ when calculating φ. As the maximum lift to drag ratio occurs at 7° for a clean blade and at 5° for a degraded blade, 6° was chosen as the target angle of incidence.