Multiple Profiles

Allowing for the use of varying aerofoil profiles along the length of the blade should prove a very useful tool. A designer may wish to use a thicker section near the root to cope with the higher structural forces, a thinner section at the tip to improve performance and some intermediate profile in between. Our main purpose for providing this capability, however, was to allow us to investigate the effect of surface degradation over different portions of the blade.

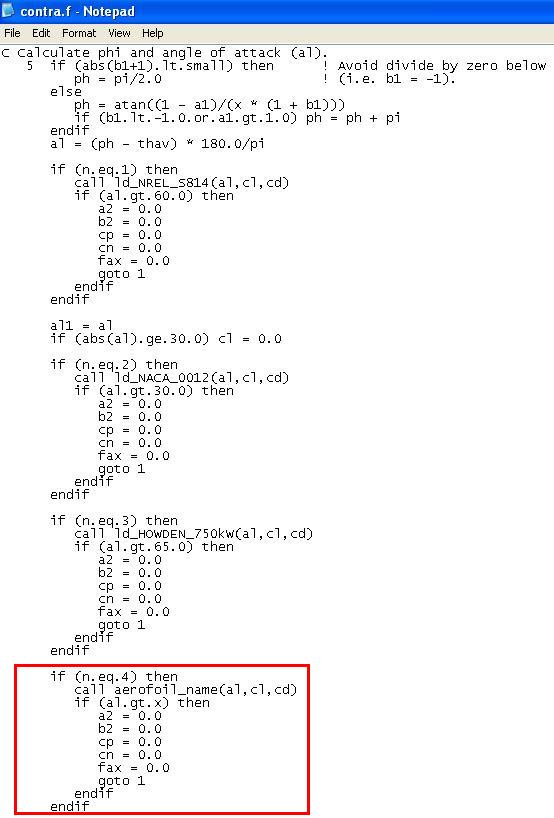

The BEM programme will ask how many of the 20 elements are required in each of the root, middle and tip section. If these 3 inputs do not total 20, the user will be asked to provide them again.

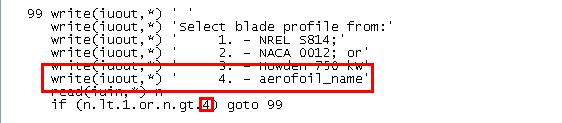

The user will then be asked to specify which profile should be used for each section.

Additional Profiles

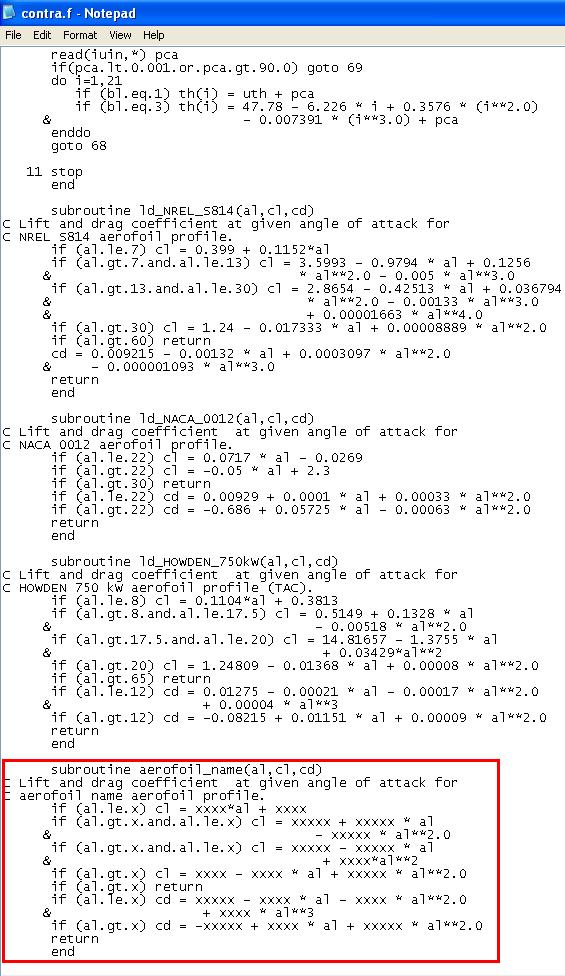

In order to make use of the multiple profile function it was thought that options to employ additional profiles should be included. This should allow a designer to investigate how using different blade section profiles may affect power output. In the programme, profiles are represented by individual subroutines which define the 2-dimensional lift and drag characteristics for that aerofoil cross-section. The original NACA 0012 subroutine was improved and subroutines were added for a NACA 63-418 section, a NACA 63-424 section and a degraded NREL S814 section. The NACA 63-4xx sections were chosen as they were to be utilised on MCT’s SeaFlow (Fraenkel).The degraded NREL S814 section was added to allow us to investigate the effect of blade fouling. A detailed procedure for adding profiles follows.

How to add your own profiles to the code.

In the BEM programme, different aerofoil profiles are represented by their 2-dimensional lift and drag characteristics in an individual subroutine for each aerofoil shape. In order to input a new profile, you will first need lift and drag polars. These can either be obtained from experimental data or if experimental data is unavailable, lift and drag coefficients can be calculated using a program such as XFOIL.

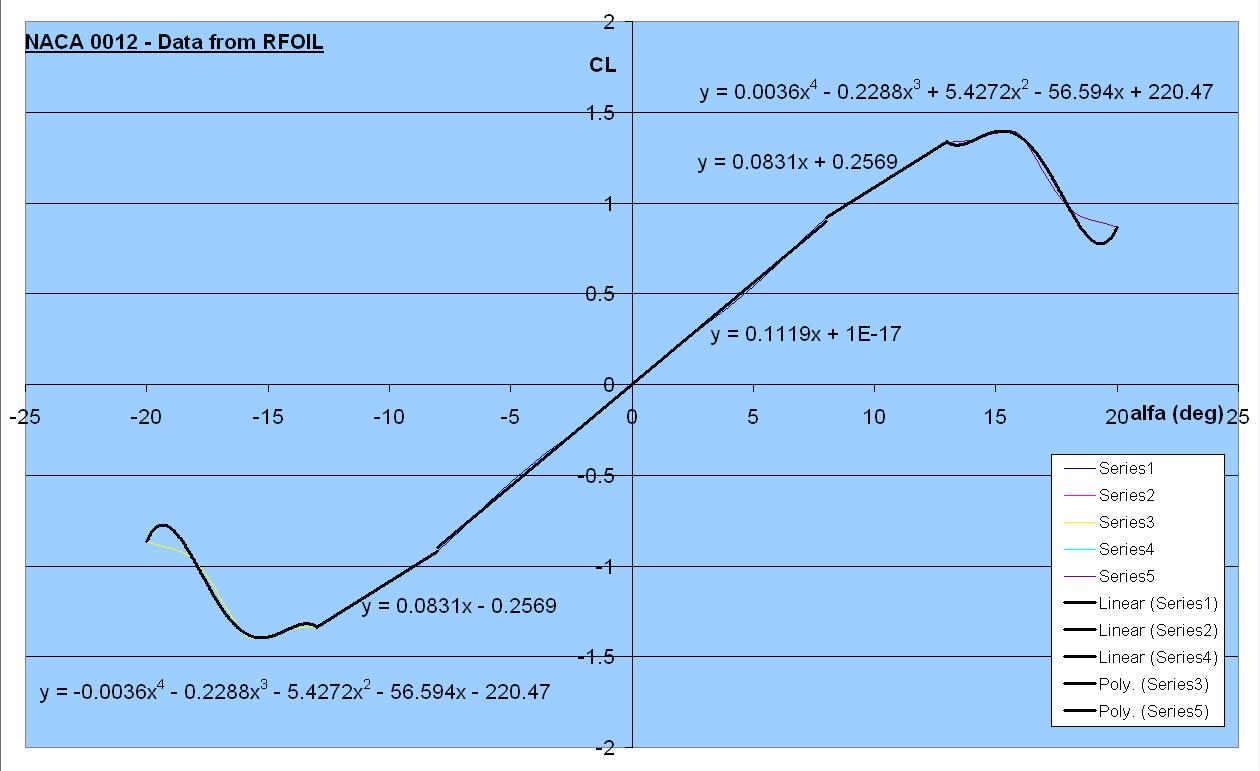

XFOIL is an open source panel solver developed by Professor Mark Drela at MIT which can calculate lift, drag, pressure and pitching moment coefficients for a given cross sectional geometry and angle of attack (AoA). This can be done for a sequence of AoA and the results output to a file. For our study we used RFOIL for this purpose. RFOIL is a programme, based on XFOIL, which has been modified at TU Delft in the Netherlands. RFOIL can provide solutions more concurrent with experimental data, particularly around stall.

Using a spreadsheet programme, such as Excel, these results can be graphed and used to create a set of polynomials describing the aerofoil characteristics. These polynomials can then be used to create a subroutine in the programme. See image below for a graphical view of how these polynomials were generated.

Steps:

- Get a set of co-ordinates for the geometry of the desired aerofoil profile and save the file in the XFOIL directory.

- (Aerofoil coordinate databases can be obtained from UIUC and AID)

- In XFOIL, load the coordinate file.

- LOAD

- aerofoil_name.dat (example)

- Specify a viscous boundary layer and chord Reynolds Number.

- VISC

- 1 500 000 (example)

- Create a file to save outputs to.

- PACC

- output.pol (example)

- Define a range of angles of attack to calculate over and the interval between values.

- ASEQ

- -25 (example)

- 30 (example)

- 1 (example)

- Open output file in spreadsheet programme. (Data may require some formatting into columns.)

- Graph CL vs. α and CD vs. α

- Use trend-lines to get polynomials approximating curves. (Data may need to be separated into several curves.)

- Insert polynomials into a new subroutine in the Fortran source code and add in references to new subroutine. (See images below.)

NB: The third revision to the source code occurs twice.