Redox flow batteries are electrochemical cells where chemical energy is provided by two components contained within the system in liquid form. “Redox” refers to the chemical reduction and oxidisation reactions employed within the battery to store energy in liquid electrolyte form, which flow through a battery of electrochemical cells during charge and discharge [1].

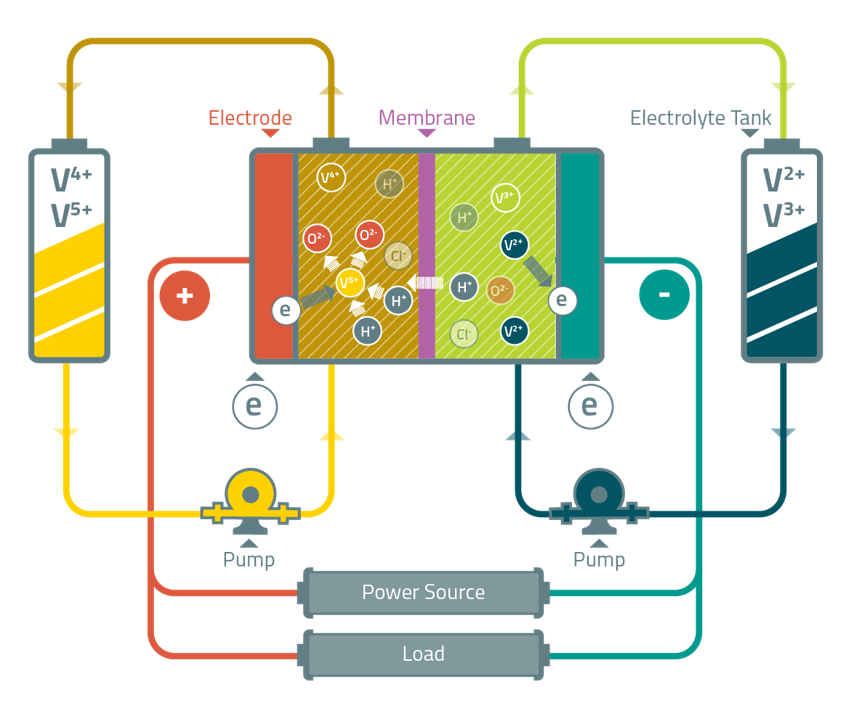

During discharge, an electron is released via an oxidation reaction from a high chemical potential state on the anode side of the battery. The electron then passes through an external circuit to do useful work, before being accepted via a reduction reaction at a lower chemical potential state at the cathode side of the battery. In charging, the direction of current and chemical reactions are reversed. The diagram below shows an all-vanadium redox flow battery (Vanadium Batteries - Australian Vanadium, 2018)[2] :

During discharge, an electron is released via an oxidation reaction from a high chemical potential state on the anode side of the battery. The electron then passes through an external circuit to do useful work, before being accepted via a reduction reaction at a lower chemical potential state at the cathode side of the battery. In charging, the direction of current and chemical reactions are reversed. The diagram below shows an all-vanadium redox flow battery (Vanadium Batteries - Australian Vanadium, 2018)[2] :

The process of of developing industry-scale, economically viable redox flow batteries is ongoing. However, the characteristics of these batteries are suited to grid-scale storage applications, with a small number currently in operation. The largest of these being a 15MW/60MWh battery located in Minami Hayakita substation in Japan. Batteries of a much larger scale are currently in the commissioning stages- with a 200MW/800MWh being developed in Dalian, China expected to be completed by late 2018 [3][4].

These batteries have the advantage of a flexible layout due to separation of the power and energy components. This layout also holds the additional benefit of only a small percentage of the total electrolyte capacity will flow through the elctrochemical stack at any given time. In the event of a fault condition, flow can be stopped- reducing the vulnerability to uncontrolled energy release. This is in contrast to other battery systems, where the full energy of the system is connected at all times [1].

The power capacity of these systems can be specifically tailored for a load or generation asset, simply by adjusting the stack size of the system. The storage capability of these systems can also be independently designed to fit the needs of the application. Storage capacity is dictated by the tank size and volume of electrolyte available, with larger tanks providing an increased storage capacity [1].

In addition to these characteristics, the all-vanadium composition flow batteries (VRFB) do not suffer from fouling or cross-contamination in the event that electrolytes are accidentally mixed. VRFB's may also be left in a state of complete discharge for extended periods of time and have 100% depth of discharge, which is suited to intermittent forms of generation. These factors ensure a longer lifetime of the systems and efficiency does not degrade over time. [1]

Concerns with VRFB's, and redox flow batteries as a whole, relate to their energy density. The energy to volume ratio for these systems are poor when compared to other conventional storage batteries. This results in VRFB's occupying a larger area than similar, alternative batteries such as Lithium Ion batteries. The efficiency of these systems are also lower, with a practical range of 65-75%. [1][5]

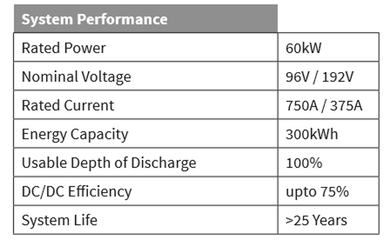

For this project, RedT 60kW/300kWh VRFB's were selected. The benefits of the all-vanadium composition, with a specified lifetime of 25 years were considered advantageous for this project. The modular nature of the systems also ensures that the storage capacity and power output may be scaled up or down depending on the predicted outputs from each case study [5].

These batteries have the advantage of a flexible layout due to separation of the power and energy components. This layout also holds the additional benefit of only a small percentage of the total electrolyte capacity will flow through the elctrochemical stack at any given time. In the event of a fault condition, flow can be stopped- reducing the vulnerability to uncontrolled energy release. This is in contrast to other battery systems, where the full energy of the system is connected at all times [1].

The power capacity of these systems can be specifically tailored for a load or generation asset, simply by adjusting the stack size of the system. The storage capability of these systems can also be independently designed to fit the needs of the application. Storage capacity is dictated by the tank size and volume of electrolyte available, with larger tanks providing an increased storage capacity [1].

In addition to these characteristics, the all-vanadium composition flow batteries (VRFB) do not suffer from fouling or cross-contamination in the event that electrolytes are accidentally mixed. VRFB's may also be left in a state of complete discharge for extended periods of time and have 100% depth of discharge, which is suited to intermittent forms of generation. These factors ensure a longer lifetime of the systems and efficiency does not degrade over time. [1]

Concerns with VRFB's, and redox flow batteries as a whole, relate to their energy density. The energy to volume ratio for these systems are poor when compared to other conventional storage batteries. This results in VRFB's occupying a larger area than similar, alternative batteries such as Lithium Ion batteries. The efficiency of these systems are also lower, with a practical range of 65-75%. [1][5]

For this project, RedT 60kW/300kWh VRFB's were selected. The benefits of the all-vanadium composition, with a specified lifetime of 25 years were considered advantageous for this project. The modular nature of the systems also ensures that the storage capacity and power output may be scaled up or down depending on the predicted outputs from each case study [5].

(Redt Energy | Industrial Energy Storage Solutions, 2018)[5]

The figures above show external and internal views of the RedT 60kW/300kWh battery. The battery consists of four modules, each with 3x 5kW cell stacks and 75kWh of electrolyte storage. The datasheet below provides data which will be used in the modelling section of this project.

(Redt Energy | Industrial Energy Storage Solutions, 2018)[5]

[1] Redox Flow Batteries | Energy Storage Association. (2018) Available: http://energystorage.org/energy-storage/technologies/redox-flow-batteries [Accessed: 10 May 2018].

[2] Vanadium Batteries - Australian Vanadium. (2018) Available: http://www.australianvanadium.com.au/vanadium-batteries/ [Accessed: 10 May 2018].

[3] Keashly, L. (2018) Sumitomo Electric 60 Megawatt Hour Vanadium Redox Battery For Hokkaido - Vanadiumcorp Resource Inc.. Available: http://www.vanadiumcorp.com/newsblog/170-sumitomo-electric-60-megawatt-hour-vanadium-redox-battery-for-hokkaido [Accessed: 11 May 2018].

[4] Weaver, J. (2018) World’S Largest Battery: 200MW/800Mwh Vanadium Flow Battery – Site Work Ongoing. Available: https://electrek.co/2017/12/21/worlds-largest-battery-200mw- 800mwh-vanadium-flow-battery-rongke-power/ [Accessed: 11 May 2018].

[5] Redt Energy | Industrial Energy Storage Solutions. (2018) Available: https://redtenergy.com/ [Accessed: 11 May 2018].