Introduction

Technology incorporating an oscillating hydrofoil varies considerably from more commonly used rotational MEC devices. The oscillating hydrofoil induces hydrodynamic lift and drag forces due to a pressure difference on the foil section caused by the relative motion of the tidal current over the foil section. These forces induce a resultant tangential force to the fixing arm which by driving reciprocating hydraulic rams pump, high pressure hydraulic fluid to turn a hydraulic motor and electrical generator. This section will highlight the principles of operation, the degree of complexity in optimising the device, the mathematical model developed; draw some conclusions and consequent recommendations.

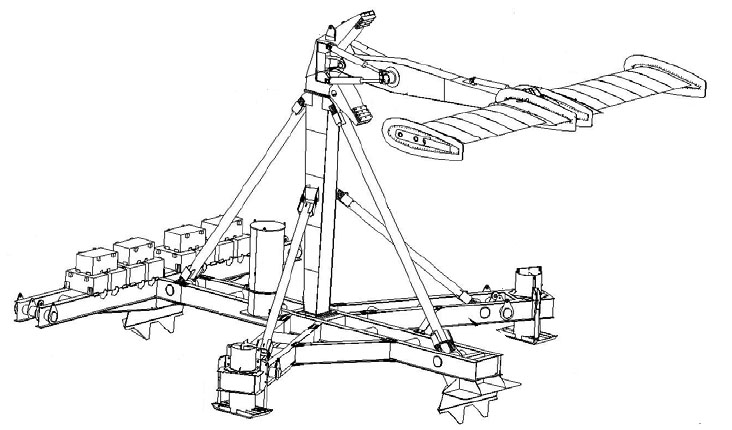

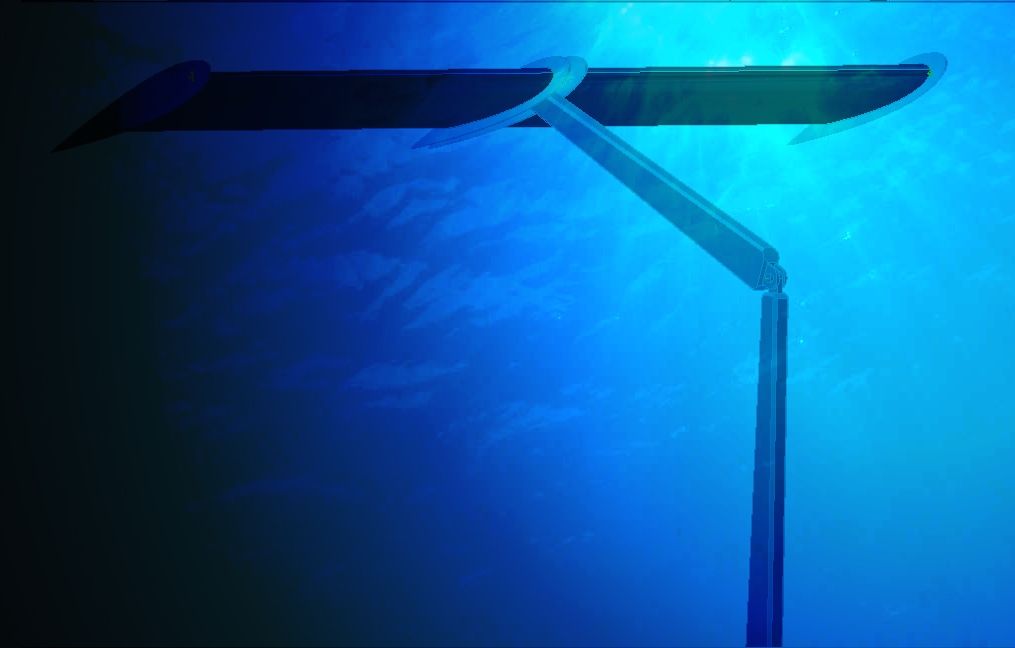

Engineering Business Ltd., in conjunction with funding from the

DTI, developed the “Stingray” oscillating hydrofoil

as a developmental prototype to prove the robustness of the concept,

the design and technology and the economical feasibility. As it

stands the inflated development costs of this device in the current

economic climate is prohibitive and has caused the project to

be suspended. The lessons that were learned from the development

and testing of the full scale 150kW prototype and have been implemented

in a large scale second generation model to be developed and tested

at a later date.

The model outlined by the developemtnal nature

of the device has similar principles of operation to that of "Stingray"

however our model is generic in nature and hence no direct comparison

relating "Stingray's" performance should be extrapolated.

Principals of operation

The main principal of operation as introduced

above is relatively quite simple. Given a positive or negative

angle of attack relative to the tidal stream in-flow, the hydrofoil

will rise and fall in an oscillating motion. The rate at which

this cycle occurs is interdependent on a considerable number of

hydrodynamic and mechanical variables.

The lift which drives the device is dependant on the flow velocity

and density, the foil surface area and aspect ratio and the foil

profile characteristics, namely it’s lift and drag coefficients

for an optimum angle of attack.

For further explanation of hydrofoil dynamics

please see hydrodynamics section

Figure 1 Stingray Assembly © Engineering Business Ltd 2005

Unlike conventional rotational technologies which once operational generate, at constant rotational speed, the lift acting on the oscillating hydrofoil approximates a sinusoidal decay from the horizontal to vertical arm positions. This non linear velocity and loss in momentum cause the device to inherently have a large degree of mechanical complexity in developing and optimising the devices power output.

As the lift decays sinusoidaly, the degree of oscillation has

to be limited (approx 35°) to prevent significant loss of

lift. The maximum lift is governed by empirical optimum angle

of attack. This angle of attack is relative to the inflow velocity,

and as the hydrofoil is continually in motion through the inflow,

this angle of attack must be controlled and dynamically optimised

to maintain efficient performance.

This is achieved by programme logic control (PLC), which continually

monitors mechanism parameters, the system hydraulic pressure,

the inflow velocity and the arm position. The PLC signal then

controls a hydraulic ram mounted on the oscillating arm to actuate

the hydrofoil angle of attack. Holding the hydrofoil stably at

its optimum angle of attack is critical, if the foil tends to

wobble it significantly reduces lift, increases drag and decreases

the overall cycle time.

Furthermore this same system is used to overcome the pitching

moment on the hydrofoil, stop its motion and return the cycle

in the opposite direction. This characteristic is the single most

limiting factor of the device. In changing the direction of oscillation,

up to 15% of the device power rating is spent in firing hydraulic

pressure accumulators to rapidly change the angle of attack. Similarly

if this accumulation pressure is reduced, the cycle time decreases

and the overall power output is decreased.

Lastly monitoring & optimisation of power extraction is also

required. As the lift and angular velocity is sinusoidal in nature

so is the resultant power curve.

Power take-off from the cycle however is not constant and neither

sinusoidal. Power extraction cyclically occurs only after the

arm’s angular velocity has reached a rated cut in speed

to allow the device to build up speed and power.

Modelling

The modelling undertaken and outlined below, is generic in comparison with the discussion above, as the requirements of this project is to indicate the power output and power coefficient for a given flow velocity and device size.

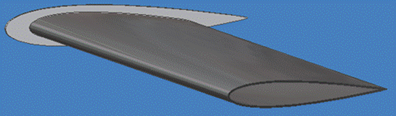

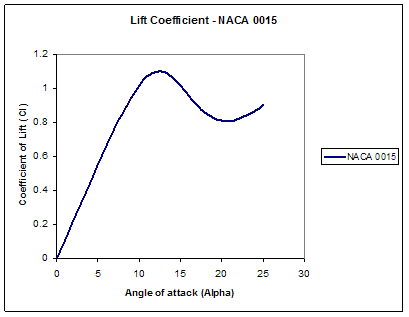

A NACA 0015 symmetrical, high lift, low drag foil profile was chosen to be the basis of the hydrofoil characteristics. The foil is symmetrical, and hence operates for positive and negative angles of attack. The hydrodynamic properties of the profile have been tested and are well documented. Foil endplates prevent the propagation of wingtip vortices and consequent loss of lift and induced drag and enables simplified analysis.

Figure 2 NACA 0015 Section Profile

The lift and drag coefficients which are arrived at empirically

are illustrated below for varying angle off attack. The optimum

angle of attack can be seen to be at 12°. Larger angles of

attack will induce drag and the device will stall, reducing lift,

and power output.

Figure 3 Coefficient of Lift

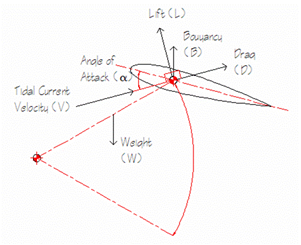

Figure 4 System Forces

Assuming that the hydrofoil angle of attack (a) is maintained

at a constant the resultant lift generated can be calculated by;

![]()

Equation 1 Lift Equation

Where ![]() is water density,

is water density,![]() is bulk flow velocity, S is foil planer area and CL

is the lift coefficient.

is bulk flow velocity, S is foil planer area and CL

is the lift coefficient.

Similarly the Drag experienced is calculated using;

![]()

Equation 2 Drag Equation

Where CD is the drag coefficient.

Further assuming that the buoyancy forces from the GRP hydrofoil

balances the weight from the steel arm structure to prevent cyclic

loading on the device, the system forces are resolved into tangential

and normal forces to the direction of oscillation.

Equation 3 Resolved System Forces

The tangential force T for a given angle of oscillation ß is given by;

Equation 4 Resultant Tangential Force

It should be noted that the drag experienced on the foil, can

have positive effects depending on the phase of the cycle. Further

more induced drag and stall at extreme angles of rotation can

be used to accelerate change in oscillation direction and decrease

the cycle time.

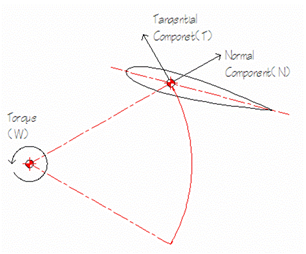

The torque applied around the centre of rotation is dependant

on the arm length or the radius of rotation. However, the longer

the arm, the more it weighs disturbing the buoyancy-weight balance

of the arm-foil assembly. Further it will affect the system inertia

and the cycle time accordingly.

The instantaneous torque experienced is a product of the resultant

Tangential force above by the Arm length.

Equation 5 Instantaneous Torque

The cyclic torque is resolved by calculating the

resultant tangential forces through the cycle angle of rotation

from ßmin to ßmax.

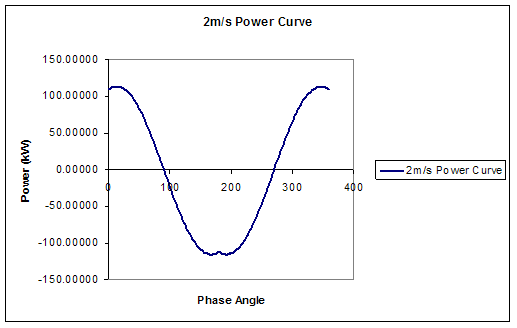

The output power cycle can then be calculated for a specified

cycle time Ct.

Equation 6 Instantaneous Power

Where w (omega) is the angular velocity in radians per second,

and phi is the cycle phase angle.

Again the cyclic power can be evaluated over the cycle and a root

mean square gives the associated cycle power.

Fig. 7 shows the resultant power curve for a model with a 2m/s flow velocity, a hydrofoil area of 45m2, arm length of 10.9metres and operates with a power coefficient (CP) of 0.12.

Figure 7 Model Resultant Power Curve

back to top

Conclusions

It is apparent that the oscillating hydrofoil

has a large degree of complexity with many system variables. This

complexity requires continuous monitoring to operate the device

at a considerable loss of power to the hydraulic actuation system.

The device operates at a low coefficient of power. Optimisation

of the control system governing angle of attack is needed to decrease

cycle time, increasing the power output.

Simplification of the design to maintain system momentum in a

rotational setup may reduce the power lost in actuating the foil

angle of attack and minimise hydraulic pressure losses and hence

increase output power. This could also be achieved by operating

3 foils out of phase with their respective hydraulic systems linked.

This would automatically provide a continuous high pressure reserve

to actuate each of the alternate foils and also minimise resultant

lift from the seabed reducing mooring requirements & costs.

A full set of results is available in the results download package here.

References

| 1 | DTI, The Engineering Business: Research and Development of a 150kw Tidal Stream Generator - Phase 1 [ETSU T/06/00211/00/REP; URN No 02/1400]. [PDF] 2002 [cited 02 May 2006]; Available from http://www.dti.gov.uk/renewables/publications/pdfs/T00211.pdf |

| 2 | DTI, The Engineering Business: Research and Development of a 150kw Tidal Stream Generator - Phase 2 [ETSU T/06/00211/00/REP; URN No 02/1400]. [PDF] 2003 [cited 02 May 2006]; Available from http://www.dti.gov.uk/renewables/publications/pdfs/T00211.pdf |

| 3 | DTI, The Engineering Business: Stingray Tidal Stream Energy Device Phase 3 [ETSU T/06/00230/00/00; URN No 05/864]. [PDF] 2005 [cited 02 May 2006]; Available from http://www.dti.gov.uk/renewables/publications/pdfs/T00211.pdf |

| 4 | SHIVERS, J. and CARPENTER, P., NACA TN-4356: Effects of Compressibility on Rotor Hovering Performance and Synthesized Blade-Section Characteristics Derived from Measured Rotor Performance of Blades Having Naca 0015 Airfoil Tip Sections, 1958 NASA Langley |

| 5 | MUNSEN, B., et al., Fundamentals of Fluid Mechanics. 3 ed. 1998, New York: John Wiliey & Sons. pp. 877. ISBN |

Go back to Contents

Home

Home