Heat Pumps

Heat pumps are thought to be the best technical solution to electrifying Eigg's heating demand. They can provide heating with 200-400% greater efficiency than resistance heaters, depending on the system that is chosen. However, they are considerably more costly than resistance heaters. (1)

There are three key types of heat pump. They all have the same working principle but extract heat from different mediums. The three types are; Air Source Heat Pumps (ASHP), Ground Source Heat Pumps (GSHP) and Water Source Heat Pumps (WSHP) (2).

GSHPs and WSHPs normally have a higher efficiency than ASHPs, as the medium stays at a higher, more constant temperature than the outside air. However, GSHPs and WSHP are typically five times more expensive, and require more intrusive installation (3). WSHPs were deemed inappropriate for further analysis due to the lack of distribution of water source on Eigg.

ASHPs and GSHPs were both analysed for comparison. It was found that ASHPs, with an air-to-air configuration were most appropriate for the Isle of Eigg predominantly for financial reasons. This financial comparison can be found here. There were concerns that an air-to-air configuration may be inappropriate for Scottish climates. A full discussion on this topic can be found on the useful links section.

Outside Unit of an Air Source Heat Pump

How does a heat pump work?

A heat pump is designed to move thermal energy from a cold space to a warmer space, opposite to spontaneous heat flow. This might sound like a violation to the second law of thermodynamics, which states that heat cannot by itself pass from a cold to a hot space.

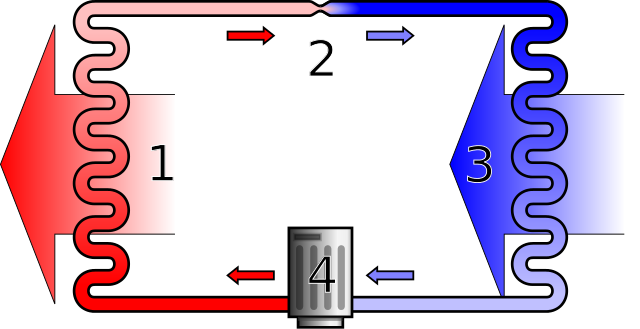

The key to how this works is that the heat does not pass by itself, but is driven by a compressor in the refrigeration cycle. This is essentially the same principle used by refrigerators, but in reverse as the goal of a heat pump is to heat the inside space. The figure below shows the basic operating principle of a heat pump. It is drawn as a cycle because a pressurised working fluid is being circulated. The four stages are as follows:

Stage 1 – Condensation

The working fluid, which is in the form of hot pressurised vapour, enters a heat exchanger or 'condenser'. Here, heat is extracted so that the inside space can be heated. The fluid is subsequently cooled until it condenses while the pressure is still high.

Stage 2 – Expansion

The pressure of the working fluid is lowered, normally through an expansion valve. The fluid is now cooled and has low pressure.

Stage 3 – Evaporation

The working fluid enters a heat exchanger or 'evaporator'. This is the outside unit of the heat pump. In this stage, heat is absorbed from the environment by the now cooled fluid until it boils.

Stage 4 – Compressor

The fluid which has been heated until it condensed is still at a low pressure. In this stage it enters a compressor, which increases the pressure of the fluid. The fluid is now once again in the form of hot pressurised vapour, and the cycle is repeated.

Vapor-compression refrigeration cycle (Wikimedia, public domain(4))

coefficient of performance

When discussing the efficiency of heat pumps, the term “Coefficient of Performance” (COP) is used to describe the ratio between heat produced and electrical work input. This means that a heat pump with a COP of 2 will generate two units of thermal energy for every one unit of electrical energy input, making it twice as efficient as a normal resistance heater. The higher the COP of a system, the more efficient the system is.

The COP is dependent on the temperature difference between the outside and the inside ('outside' would refer to outside the home in which the heat pump is installed). If the temperature difference is high, the achievable COP will be lower than if the temperature difference was low. For example, if it is really cold outside and the inside unit delivers heat at a high temperature, then the temperature difference will be high. This will lead to a lower COP because more work will have to be put into the compressor to increase the pressure of the fluid. Also, because it is colder outside, less heat is absorbed in the evaporator. This means that the efficiency is lowest when the heating is needed the most.

Regarding GSHPs and WSHPs the COP will not change much through a year because the temperature difference stays fairly constant. With an ASHP, however, the outside air temperature will change throughout the seasons, making the COP fluctuate.

estimating cop values

ASHPs

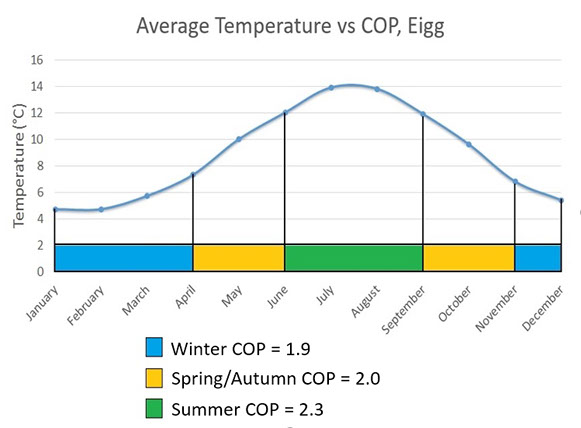

Due to practicality and cost concerns, ASHPs were chosen for Eigg. As mentioned previously, this configuration will have a changing COP throughout the year. To model the required power generation with heat pumps installed in all buildings on Eigg, the COP through the year had to be estimated.

To estimate the COP, the year was divided into three categories corresponding to seasons: winter, spring/autumn and summer as shown in the figure to the right. This was based on the average annual temperature on Eigg, shown by the blue line. The average temperature for each season was then correlated with COP data from field tests of ASHPs from SINTEF. (5,6)

This method provided an estimation for COPs to be used in the simulation. However, the numbers have uncertainties as the temperature fluctuation throughout the year is simplified into three seasons. Also there are uncertainties in the actual COP of heat pump systems due to installation methods, sizing and the manufacturer chosen. The COP values chosen can be seen as conservative, and could in practice turn out to be higher with correctly installed, properly sized heat pumps.

GSHPs

Field tests carried out by the Norwegian government enterprise, Enova SF shows that the actual COP value for GSHPs is quite diverse (5). COP values between 2.5 and 4.5 was the norm. The lowest of these two values may indicate that the heat pump has not been properly sized, or uses an inefficient way to deliver the heat.

For the simulation a COP = 3.5 was estimated for GSHP. This is an average between the lowest and highest number found in the ENOVA SF study.

Cost of heat pumps

Heat pumps are expensive heating systems compared to traditional heating systems using fossil fuels. However, when choosing to electrify the heat network, heat pumps reduce the electricity needed compared to resistance heating, and so can be a viable investment.

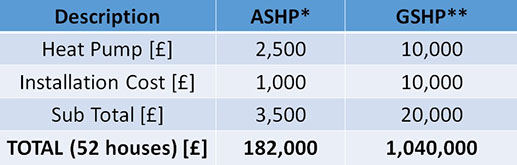

It is difficult to give an accurate cost estimate for an ASHP system as many different models exist, and the systems have to be scaled to the size of the house. The prices used and shown in the table to the right are based on a medium sized system with a simple air to air configuration. The cost of a system like this will be in the order of £2500, and installation cost for each of the system is likely to be about £1000. (7)

The total cost per building is therefore estimated as £3,500, and with 52 houses on Eigg, the total price is £182,000 for upgrading all homes.

GSHPs are a lot more expensive, especially the installation of the system. The cost is likely to be in the order of £15,000 - £20,000. The higher cost was chosen in this scenario because Eigg is a remote island. Because of this, the price for workers would be higher, as they will have to travel from the mainland and probably stay overnight.

Pricing for Heat Pumps on Eigg

*The ASHP is in an air to air configuration, as this is the cheapest and easiest to install. Only an outside and an inside unit is needed, and it can be installed in less than a day.

**The GSHP system is much more expensive as it requires the drilling of boreholes which takes several days and specialised equipment. The system itself is more complex as it normally uses underfloor heating and often includes hot water heating.

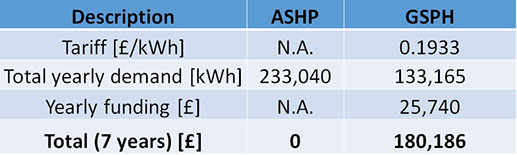

Funding through RHI tariffs (8)

To encourage the development of renewable heat technologies the UK Government implemented the Renewable Heat Incentive (RHI). The scheme will pay a fixed price per kWh for eligible renewable heating technologies. The scheme supports some biomass and heat pump systems in addition to solar thermal panels.

The RHI’s policy on heat pumps is that you can only claim support for ground-to-water heat pumps and air-to-water heat pumps. Since the ASHP system chosen is an air-to-air configuration, no support would be given. The GSHP system on the other side will receive funding.

The support is in the form of tariffs paid out over a period of seven years for a renewable heating system. The tariff as of April 2016 is 19,33 pence/kWh for GSHPs.

This would mean that the ASHPs would receive no funding, and GSHPs would receive a total of ~ £188,186 for all the heat pumps on Eigg. Effectively this would reduce the overall price of GSHPs down to £859,814.

Paybacks through RHI paid out over a maximum of 7 years for eligible systems

Deciding between GSHP and ASHP on Eigg

By looking at the cost between ASHPs and GSHPs it might seem obvious that ASHPs is the cheapest choice. However, the efficiency of the GSHP is almost twice as high as that of the ASHP, which over a 25 year period will have an influence. The added support of the RHI will also reduce the overall price of the GSHPs.

A cost analysis was carried out, which assumed a 25 year lifetime for each of the systems. It also looked at the difference between upgrading the houses and not upgrading them. As shown in the cost analysis the most cost effective option was ASHPs as well as upgrading the poorly insulated houses.

The reason ASHPs with an air to air configuration was chosen is because of the lower cost, and because incorporation of hot water heating is unimportant. An air to water system would cost £6,000 – £10,000 without too much added benefit. The reason hot water is unimportant is because the grid on Eigg does not export surplus energy. The idea is instead to store the surplus energy produced in the form of heat in hot water tanks, effectively providing “free hot water”. How this system would work is described in detail here.

It is worth noting that the ASHP in the air to air configuration would be highly ineffective if not the poorest houses was upgraded. This is because the hot air would then leak out through the walls and roof, dramatically decreasing the efficiency of the system.

© University of Strathclyde | TEC Eigg | Sustainable Engineering 2016