Jacket Foundations for Wind Turbines Fisker Jensen, J. (2010)

Jacket Foundations for Wind Turbines Fisker Jensen, J. (2010)The next step to extend the use of wind energy is to develop and build cost-effective offshore wind farms. The reason is that wind resources are higher offshore and the amount of energy that can by captured by wind farms in the sea is significantly higher than in onshore areas. As a result, off-shore wind industry moves towards wind farms located in areas with greater water depths where wind blows at higher velocities and more frequently.

From the energy production point of view, it is interesting to set larger wind turbines that can capture more energy from the wind. Placing larger wind turbines means that the turbines will have higher rated power values and their annual energy production will be much higher. This also means that the size of the turbines will be greater, too. Then, OWTs (Offshore Wind Turbines) must be able to withstand harder loading conditions due to the higher wind speeds and more extreme wave conditions in areas afar from the shore.

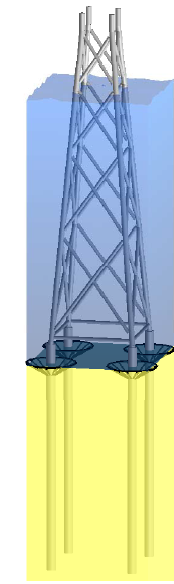

OWTs are supported by substructures connected to the seabed. These substructures can consist of monopiles, gravity bases, tripod jackets or four-legged jackets. Each type of substructures has its advantages and disadvantages and can be used for different ranges of water depth values. Four-legged jackets are currently the type used in locations with highest water depths and they are in general the preferred type for depths from 35-40 m onwards.

There is a limit of water depth for which supported substructures can be deployed. This limit is considered to be 60-70 m and jackets are the substructures that can best withstand wave and wind loads at these sites. For water depths beyond these values floating foundations would be the most reasonable approach to support OWTs. In general, the most remote offshore wind farms are presently set in locations with water depths between 40 m and 50 m. Therefore the stage of floating foundations has not been achieved yet. This being so, jacket substructures are the key part for offshore wind farms with increased installed power and higher capacity to produce energy annually.

Jackets substructures are connected to the seabed by pile-sleeve pile connection joints with a grout material. Pre-piled grout joints are the most used in the offshore wind industry. From 2009 many wind farms in the North Sea have reported problems and failures related to these grout joints. These problems have jeopardised the operation of wind farms, which had to face long periods of maintenance to fix them in order to avoid the structural collapse of the wind turbines.

These problems have been the main limitation in the operation of off-shore wind farms in recent years. That is the reason why is extremely important to design reliable grout joints that can with withstand the strains due to the wind loads on the wind turbine and the wave loads on the jacket substructures. By doing so, we can secure the normal operation of offshore wind farms without annual energy production being endangered by the risk of structural collapse.

The aim of this project is the study of pre-piled grout joints as means of guaranteeing the correct operation of offshore wind farms and their energy production without unexpected events coming from foundation failures.

BULLETPOINTS

Need of producing more energy from renewable sources.

Need of producing more energy from renewable sources.

Wind energy is a key source: developing cost-effective off-shore wind farms.

Wind energy is a key source: developing cost-effective off-shore wind farms.

Towards greater water depths to produce more energy.

Towards greater water depths to produce more energy.

Larger wind turbines: capture more energy and higher rated power values.

Larger wind turbines: capture more energy and higher rated power values.

Supported substructures: monopiles, gravity bases, tripods and four-legged jackets.

Supported substructures: monopiles, gravity bases, tripods and four-legged jackets.

Four-legged jackets supported foundation for maximum water depths (40-50 m currently).

Four-legged jackets supported foundation for maximum water depths (40-50 m currently).

Limit of water depth for supported substructures: 60-70 m (jackets).

Limit of water depth for supported substructures: 60-70 m (jackets).

Beyond this limit: Floating foundations.

Beyond this limit: Floating foundations.

Jackets are connected to the seabed by pile-sleeve pile grout joints.

Jackets are connected to the seabed by pile-sleeve pile grout joints.

From 2009 many problems and failures reported in wind farms in the North Sea.

From 2009 many problems and failures reported in wind farms in the North Sea.

Problems jeopardised the normal operation of offshore wind farms.

Problems jeopardised the normal operation of offshore wind farms.

Long periods of maintenance to avoid structural collapse.

Long periods of maintenance to avoid structural collapse.

Need of joints that withstand the operation conditions.

Need of joints that withstand the operation conditions.

Project aim: study grout joints to secure energy production of offshore wind farms.

Project aim: study grout joints to secure energy production of offshore wind farms.