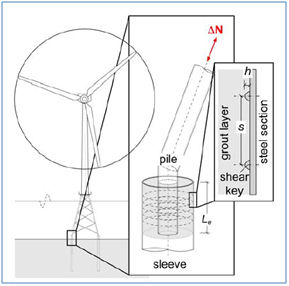

Additionally, weld beads known as shear keys are used as interlocks and aligned in the circumferential direction on the surfaces of the outer and inner tube facing the grout in order to increase the load bearing behaviour of the connection.

Grouted joints for OWT can be subdivided into pre-piled and post-piled connections. A pre-piled connection is the jacket with grout pin placed inside the previously driven piles and the piles here represent the sleeves so they can be called pile-sleeve. On the other hand, in a post-piled connection the pile-sleeve is used as a template to drive the foundation piles after setting the substructure

(Schaumann, et al., 2013). Pre-piled grout joints are the most used in the offshore wind industry.

These kinds of connection are well known from the offshore oil and gas industry. They offers the possibility of compensating inclinations induced by pile driving action and therefore are considered a good solution for offshore substructures. However, offshore oil and gas platforms mainly withstand static axial loads whereas OWTs are loaded by significant dynamic action coming from the wind. Hence, fatigue is a key issue regarding the performance of the joints.

Despite that fatigue dominate the load bearing behaviour of the joints for OWTs, there are no valid design recommendations for the fatigue design of grouted joints with shear keys. Geometric dimensions and material strength of the these connections deviate from current offshore design standards (Schaumann, et al., 2010) such as EN ISO 19902, NORSOK N-004, GL 2005 or DNV-OS-J101.

One of the most relevant research projects in this field is the BMU-research project 'GROW-Grouted Structures for Offshore Wind Turbines'. This project conducts several experimental investigations in this type of grouted connections at the Institute for Steel Construction in Hannover, ans is responsible for the majority of publications and data available in this field.

According to (Schaumann, et al., 2010) while grouted joints for monopiles are mainly exposed to bending, grouted joints in jackets are used for the load transfer of high frequency variable axial loadings and torsional moments. Current offshore standards include empirical design formulae derived from axial load capacity tests by varying steel and pile diameters, grout strengths, overlap factors and the influence of the shear keys.

This project has tackled the study of an industrial case of a grout joint under standard peak load conditions by implementing a simple Finite Element Analysis.