Plain grout joints are not suitable for jacket substructures, as well as being not suitable for monopiles. Therefore shear keys are essential since shear strength is dominated by the h/s ratio of the shear keys and the compressive strength of the grout (fc).

Plain grout joints are not suitable for jacket substructures, as well as being not suitable for monopiles. Therefore shear keys are essential since shear strength is dominated by the h/s ratio of the shear keys and the compressive strength of the grout (fc).

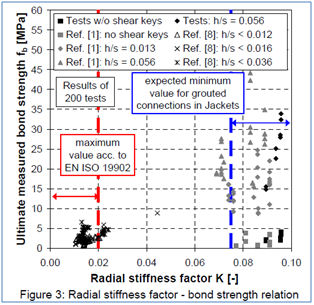

In cases of high strength grout materials and deviating stiffness relations K, the results of the design curves from ISO 19902 underestimate the force bearing capacity of the connection significantly. This can lead to very conservative design results.

In cases of high strength grout materials and deviating stiffness relations K, the results of the design curves from ISO 19902 underestimate the force bearing capacity of the connection significantly. This can lead to very conservative design results.

For grouted connections in OWECs the material strength of the filling material is considerably higher than recommended strength values of ISO 19902. In addition, the geometric dimensions deviate from the dimensions considered in the standard. As a result, radial stiffness factors are expected to be Kjacket ? 0.075 for grouted connections in jacket substructures.

For grouted connections in OWECs the material strength of the filling material is considerably higher than recommended strength values of ISO 19902. In addition, the geometric dimensions deviate from the dimensions considered in the standard. As a result, radial stiffness factors are expected to be Kjacket ? 0.075 for grouted connections in jacket substructures.

Grout layer thicknesses of 400 mm and higher have to be expected for future jacket support substructures.

Grout layer thicknesses of 400 mm and higher have to be expected for future jacket support substructures.

Shear keys have to be considered as geometric notches and therefore they lead to local stress concentrations. Shear keys with tensile stresses may lead to cracks in steel sections. Moreover, shear keys also influences the fatigue performance of brittle grout materials.

Shear keys have to be considered as geometric notches and therefore they lead to local stress concentrations. Shear keys with tensile stresses may lead to cracks in steel sections. Moreover, shear keys also influences the fatigue performance of brittle grout materials.

The risk of crushing and cracking around the shear keys is reduced using high performance grout (HPG). On the other hand, grouted connections with HPG and normal strength steel can fail due to steel yielding in the shear keys.

The risk of crushing and cracking around the shear keys is reduced using high performance grout (HPG). On the other hand, grouted connections with HPG and normal strength steel can fail due to steel yielding in the shear keys.

The stress concentration factors are influenced by the number of shear key rows. Factors could be decreased by increasing the number of shear key rows. This relates to the idea of equidistant load transfer; a higher number of shear keys leads to uniformly distributed stresses.

The stress concentration factors are influenced by the number of shear key rows. Factors could be decreased by increasing the number of shear key rows. This relates to the idea of equidistant load transfer; a higher number of shear keys leads to uniformly distributed stresses.

The stress concentration factor is additionally influenced by the notch effect, described by the shear key width to height ratio (w/h). Narrow shear keys (w/h < 2) increases stress concentration factors. On the other hand, for wide shear keys the stress concentration factor also increases. This is caused by detaching effects of steel from grout under compression stresses. Sharp edged shear keys should be avoided.

The stress concentration factor is additionally influenced by the notch effect, described by the shear key width to height ratio (w/h). Narrow shear keys (w/h < 2) increases stress concentration factors. On the other hand, for wide shear keys the stress concentration factor also increases. This is caused by detaching effects of steel from grout under compression stresses. Sharp edged shear keys should be avoided.

The distance effect (h/s effect) of shear keys is to be considered too. Large distances between shear keys lead to high stress concentrations.

The distance effect (h/s effect) of shear keys is to be considered too. Large distances between shear keys lead to high stress concentrations.

Shear keys with w/h ratios of 2 and distance ratios of h/s of 0.05 show satisfying results under tension and compression stresses.

Shear keys with w/h ratios of 2 and distance ratios of h/s of 0.05 show satisfying results under tension and compression stresses.

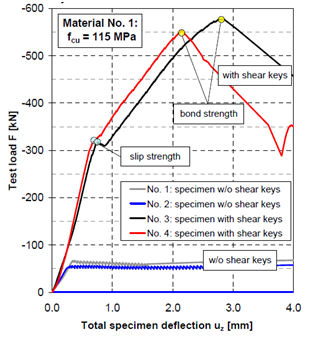

Grouted connections have been tested in the fatigue limit state. To reduce large deflections of grouted connections the maximum fatigue stresses should be limited to the slip strength. Stress values which lay between slip and bond strength will not lead to a collapse but to unacceptable vertical deflections for the connections. (Schaumann, et al., 2010). recommend a limitation of the maximum fatigue stresses up to the slip strength.

Grouted connections have been tested in the fatigue limit state. To reduce large deflections of grouted connections the maximum fatigue stresses should be limited to the slip strength. Stress values which lay between slip and bond strength will not lead to a collapse but to unacceptable vertical deflections for the connections. (Schaumann, et al., 2010). recommend a limitation of the maximum fatigue stresses up to the slip strength.