Noise and vibration.

Noise and vibration.

This comes from machinery and power generators. The consequences for the surroundings can be a reduction of the abundance of benthic organisms and disturbance to cetaceans. Jackets foundations are formed using small piles. Those pieces larger in comparison to the wavelength of the sound will have greater radiation efficiency than smaller pieces. If jackets are compared to other types of foundations such as monopiles, it is found that jackets do not transmit the sound so efficiently and have a lower impact in the environment. For that reason, the jacket foundation is preferable compared to the monopile foundation. The tripod foundation is in between.

Disturbance to the seabed.

Disturbance to the seabed.

This is generated by pile-driving and the installation of undersea cables. The consequences will be a reduction of the diversity of benthic organisms. Harmful noise is generated during piling the foundations. Because of the small pieces from which jackets are formed, the influence is over a smaller area than for monopiles. However, a number of small piles can also imply a longer period of installation.

Turbidity.

Turbidity.

The water can be murky in the construction phase due to hammering action on the seabed. The decrease of transparency in the water will decrease the quality of habitat for plankton in the water column.

Conflict of Space.

Conflict of Space.

A problem that could arise in the longer term is the presence of offshore wind farms which would create spatial conflicts with open aquaculture fields.

Reduction of environmental impact

.

Noise pollution in the seawater from OWTs has been identified as a major issue that requires further technical improvements. The range of detrimental effects associated with the turbines operation can be decreased by 5 to 30 dB which has a relevant effect on the flora and fauna around the site

(Hammar et al, 2010).

The current different technical concepts to reduce piling noise during construction are:

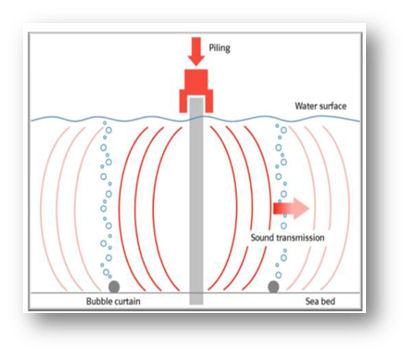

Bubble Curtains.

Bubble Curtains.

The isolation of the work zone by creating a bubble curtain can be effective enough to reduce noise by up to 30 dB

(Hammar et al, 2010). The dense screen of air bubbles required is considerably reduced in extreme flowing water.

Noise mitigation shields.

Noise mitigation shields.

A cofferdam can be installed during the construction phase of the turbine making the area isolated. The noise from piling will go either to the air or to the bottom substrate which reduce significantly the sound in the water

(Reyff 2005, in Hammar et al., 2010).

Vibro piling.

Vibro piling.

The technique consists in a vibrating hammer which works fast and makes light beats to the seabed. The hammering starts softly so the sound slowly increases. However, this method should be considered with caution because it has been shown to not work for large sized piles

(Reyff 2005, in Hammar et al., 2010).