Biomass

There are few 'clean' forms of low grade energy resources, which partially explains the popularity of coal, oil, and natural gas in today's energy economy. Should this project address sunnier climates, solar thermal may be worth investigation. Geothermal would also be ideal but these resources do not apply to Eigg. The most abundant local low-grade resource is Eigg's forestry potential, as discussed on this page.

The integrity of biomass as a carbon-neutral source is often questioned. To provide all the electricity and heat on Eigg by means of a biomass plant, the entire forest forest would be exhausted in only one year, and fully clearing the land would negate its carbon neutrality. Looking at heat and hot water alone, the demand has been estimated as 466MWh per year given the housing upgrades (as detailed in demand reduction). Analysis of the forest currently on Eigg may show whether or not it could satisfy some (or all) of this space heating demand.

There are, however, crucial limitations on Eigg's biomass potential, notably:

- Space

- Land type

- Wood species

- Population.

These are discussed at the end of this section.

evaluating eigg's current resource

Eigg's Resource

The Isle of Eigg already has forest across its central lowland, conveniently connecting their two core residential areas. This forest was investigated using a tool provided by the Biomass Energy Centre (BMEC)(1). The steps in calculating how much energy can be provided from a forest are summarised as:

- Estimate the available volume of wood;

- Convert from volume to 'green' weight;

- Convert this to the weight at a target moisture content;

- Calculate the available energy using the provided Excel spreadsheets.

Ultimately, this tool can be used in any case where there is biomass potential to test its feasibility. A number of other sources were investigated to support the calculations throughout this process, and to ensure sustainable rotation and carbon neutrality.

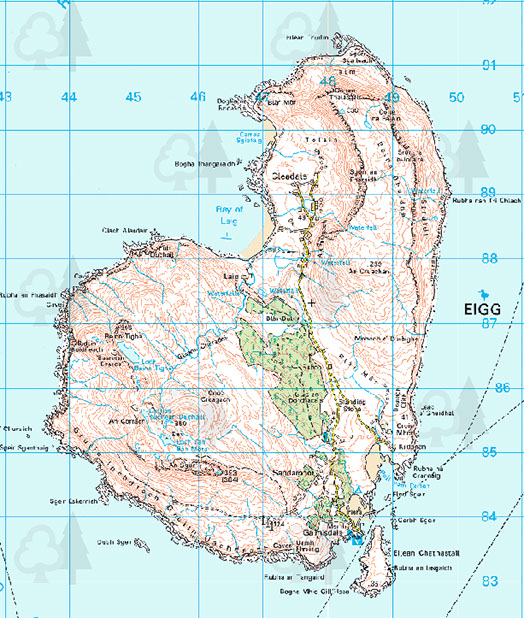

Map of Eigg showing forest in the centre of the Island (UK Gov forestry mapping tool)

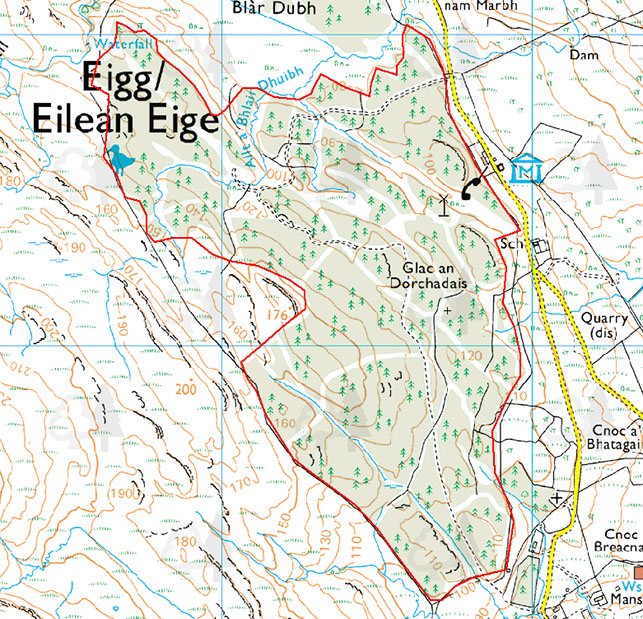

Mapping area of Eigg's forest (UK Gov forestry mapping tool)

Estimating Volume

The area of the current forest was mapped using an online tool provided by the UK Government's website on forestry. The area is drawn around and estimated at approximately 130ha (1.3km2). A small area of forest north of this is not included so as to compensate for the open areas (such as the forestry tracks and turning circles) within the drawn area.

From here, several assumptions must be made. This forest is noted to be mixed softwoods(2,3). The land is peaty, and can be considered relatively poor fertility. The forest has been essentially unmanaged for some time, but as volunteers often partake in voluntary forestry, tracks remain accessible and the wood is often cut for log fires for residents.(3) There is sufficient functioning machinery and equipment on the island, although barely used in recent years.

Given the limited data available regarding the land and forestry, on Eigg, the worst-case scenario is used to calculate the potential supply. This considers the dominant tree type to be spruce, and the potential for peaty soil and undergrowth. On low fertility soil, the forest is expected to require 60 years rotational period.(2) The estimated volume of wood grown over 60 years is calculated as 1560m3.

Green Weight* (W1)

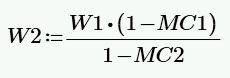

The density of Sitka spruce is given as 920kg/m3(5). Thus the total 'green weight' is simply this times 1560m3 =1.4x106kg. Using relative moisture contents, the dried weight is calculated from the equation:

Dried Weight (W2)

Air dried logs can reach a moisture content of 20%**. The 'weight' at this moisture content is calculated to be approximately 7.2x106kg.

*In the UK forestry industry, the term 'weight' in this context refers to the physical mass (kg).

**20% is the possible moisture content for the use of air-dried logs for wood burning stoves(1). Logs were chosen due to their simplicity - there is no need for specialised storage for chips and pellets, nor the equipment necessary to process the wood to make these. Logs can be dried and stored in sheds - most homes on Eigg even have log sheds and wood burning fireplaces already.

The BMEC provides coefficients for different major wood types which can be used to determine the energy in a given volume. For softwoods this is notably 1.3MWh/m3. Furthermore, the Solid Fuel Association gives a value of 2.6kWh/kg which can be used with the above weight estimation to also determine energy available (6).

These calculated values of energy range from 40GWh to 48GWh from the whole forest currently on Eigg. Given the use of wood fireplaces and stoves, generally only about 20-25% of this heat from the stove will be given out as space heating (the rest will travel upwards, through the chimney or to a boiler).(7,8) Continuing to consider a worst case scenario, approximately 9GWh of space heating can therefore be provided by the whole forest. This exceeds the 466MWh yearly demand, and would be able to supply Eigg's population for approximately 19 years. However, with a 60 year rotation period, this must be distributed over the 60 years.

Essentially, dividing this we can clarify that the forest can be sustainably rotated over a 60 year period, and in such a case would satisfy 32% of the space heating demand with insulated homes. Without housing upgrades, this would be approximately 20%.

An in depth detail of these calculations in entirety can be downloaded on the useful links page.

View of Eigg's forest from forestry track towards Laig

Managing Biomass Alongside an Electrified Heat Network

The combined use of electrification and log-burning stoves is not common practice (although one example in Scotland would be John Wheatley college, which combines ASHPs with biomass boilers (9). Means of managing such a system is therefore necessary to consider, and is discussed as part of the Optimal Solution.

costs

The cost of biomass production varies massively depending on the situation, both location and demand. The Isle of Eigg has many factors which make the consideration of biomass a viable investigation. First and foremost, costs are saved as each home already has a wood burning fireplace. Wood burning stoves are affordable enough that, if a household were to desire one, community funding would not be necessary. In such cases, the logs harvested may supply hot water heating as well as space heating dependent on the stove purchased, or perhaps further central heating if radiators were also installed.

A further convenient factor is that the island already has most of the equipment necessary for felling the forest. Forestry tracks are already in place, and there are even a community owned telehandler and crane trailer already available. Beyond this, between the low population, low demand, current heating methods, wood type and limited space on Eigg, the production of chips or pellets would be infeasible by all standards. Thus, simple felling and logging is all that is necessary.

For this, Eigg would need a shared drying shed, where the logs could be air dried for 1-2 years before use ('seasoning'). Then each home would need their own drying shed for their individual wood store. A minimum of two men would need to be employed seasonally for felling and thinning of the forest in a 'group silvicultural system' - decidedly the most appropriate management plan for this forest (10). Ultimately, this would total approximately £45000 upfront for the sheds and first year of work, and then £25000 for the workers' salaries and crop provision thereafter. Supplying a high-efficiency wood stove for space heating, with a boiler for hot water incorporated, to every home would bring this upfront cost to £166000, wih running costs remaining low. (11, 12, 13)

How To Manage

Having multiple systems to take care of heating creates a problem for the user, that is deciding which to use at any given time. In the proposed scenario for Eigg that would be deciding between turning on the heat pumps (that consumes electricity, preferably from renewable sources) or the biomass ovens.

To resolve this issue a systems must be in place that informs all users of the next day’s forecast to let users know if renewable resources will be available to use or if the back-up biomass system must be activated. An app or microcontroller could read the required data from online sources and produce a straight forward answer on which system to rely.

But the biggest issue is not technological. It would be fairly easy and inexpensive to implement a system that even turns the heat pumps on and off automatically, independent of human interaction or decision. The problem is the acceptance of said measures by the end user. Any implementation would require a lot of talking and awareness by the users. A great risk of misuse would be introduced that could lead to and increase in diesel generator activity, or in extreme cases, black outs.

Therefore, the possibilities must be discussed and understood by the users and after the information/automation system is installed it would be very wise to leave room for changes depending on user-acceptance of the system. After all, the issue more social and than technological.

limitations

As previously mentioned, the limitations on the biomass potential are mainly space, land type, wood type and population.

With regards to space, it is the ideal that - to minimise emissions from transport - biomass would be produced locally. As previously discussed (here) when investigating the potential for pumped hydro, a notable portion of land on Eigg is protected as SSSIs, and so forestry on these sites would not be ideal. Beyond this, protected sites such as the north, and harsh land as in the south, would both limit the possible forestry area further.

As far as land type goes, the soil on Eigg where forest stands currently is poor enough not to allow for most hardwoods to be viable. The land is boggy and peaty, and so predominantly coniferous trees such as Sitka spruce are be grown there. Uprooting them and replacing with short rotation coppices, for example, would result in losing the carbon neutrality of the forest. Ultimately, softwood biomass is simply not as energy dense as hardwood, and so the land type on Eigg is what indirectly leads to the inconvenience of having to use softwood.

Ultimately there is now the question of why this forest has not been used before, as most homes already have wood burning stoves? In truth it is used, people often cut their own wood as they please. The reason it is not currently supplying its full 30% demand potential is simply because there is no industry. As Eigg is such a small island, and with a greying population, there is simply nobody to work in the forestry and it seems that this is the core reason to its abandonment. Often, volunteers travel to Eigg to work on conservation, and there is potential that this may be a solution to this issue - instead of importing fossil fuels, importing temporary workers.

further work

On the Isle of Eigg, there have been limitations as discussed. However, there are a number of means by which the contribution of biomass may be heightened. Suggestions for this may include:

- Incorporating biomass hot water boilers to negate need for excess electricity boilers. Generally, wood stoves or fireplaces only pass 30% of the energy out as space heat - the rest goes up the chimney or flu. This extra 55% (assuming overall 85% efficiency) may be used to heat hot water on a back burner, as is common. However, the core downfall is that these log stoves and fires must be up-kept manually, so somewhat of a lifestyle change is necessary.

- Similarly to above, the water heated in the boilers may actually fuel radiators in large homes, increasing the space heating available. This would cost more to install, and second boilers would be needed for reliable hot water.

- Increasing the size of the forest may be difficult with space limitations, but by no means impossible. Extensive opportunity mapping and planning could perhaps even double the current resource.

- A gradual change in wood type may be worth investigation, such as thinning the forest and planting short rotation coppice plants in the space. However, this may not be possible with the peaty land type, and would likely result in release of more carbon emissions than it sinks.

© University of Strathclyde | TEC Eigg | Sustainable Engineering 2016