Heating Supply

The heating supply options we investigated for BRE Visitor Centre consist of:

- Electric Heaters

- Air Source Heat Pump (ASHP)

- Ground Source Heat Pump (GSHP)

- Biomass Boiler

Electric Heaters

The heating supply at the Visitor Centre is currently provided by electric heaters. These are two, 2 kW bar heaters, which have the option to be set at 750W, 1250W or 2kW. There is also a dial on each to increase or reduce temperature. There is no timer control and they have been used profusely, particularly overnight. It has been estimated that the heaters have been used for 1,660 hours per year, using approximately 60.4kWh/m2 from November to April.

The electric heaters were not part of the initial plan, but a temporary solution after a communication fault had been identified between the original Air Source Heat Pump (ASHP) unit and the boiler.

Figure 1: Electric Heater

Figure 1: Electric Heater

Air Source Heat Pump (ASHP)

The story behind it

The original 8.5 kW ASHP (Mitsubishi Ecodan EHPT20X - VM2HA) was located on the roof and was connected to a 210 litre unvented coil cylinder located in the plant room. This distributed heat to the whole building via a manifold to the underfloor heating system, including full zone and temperature control.

In October 2013, the boiler unit presented a fault, indicating that the external ASHP unit was not working correctly. Following an investigation by M&E contractors it was found that there was indeed a fault, related to the communication capabilities between the ASHP and the boiler unit. However, the unique procurement method adopted by the Visitor Centre construction team meant that no warranty was in place to ensure a quick repair could be made.

Temporary electric heaters were then provided to the Visitor Centre in the week commencing on the 4th of November 2013, as particularly the security staff were beginning to feel cold as external temperatures fell.

Figure 2: Old ASHP unit on the roof

Figure 2: Old ASHP unit on the roof

Our recommendation

We investigated on the replacement of the old Mitsubishi ASHP with a new one. Specifically, the model investigated is a Glow-worm Envirosorb 5 Clearly Heat Pump (5 kW), as shown in Figure 3. This can be commissioned to work as before (air to water), providing heat to the Visitor Centre via the underfloor heating system.

This can work efficiently within a wide range of temperatures, as seen in Table 1, compatible with the climate of Glasgow area. If the ASHP is not able to meet the peak demands (up to 5 kW) during the coldest periods of the year, the residual amount of energy will be provided by the electric heaters. This might happen only for a few times during the winter, therefore the need for back-up from electric heaters remains relatively small. Nevertheless, this has been analytically incorporated in our study, based on the maximum output (kW) and Coefficient of Performance (COP) values, as displayed in Table 1.

Figure 3: Glow-worm Envirosorb 5 ASHP (5 kW)

Figure 3: Glow-worm Envirosorb 5 ASHP (5 kW)

| Water Flow 35 oC | Units | Glow-worm Envirosorb 5 kW |

|---|---|---|

| Air -5 oC | kW | 3.1 |

| COP | 2.45 | |

| Air 2 oC | kW | 4 |

| COP | 3.1 | |

| Air 7 oC | kW | 4.8 |

| COP | 3.8 | |

| Air Temperature Range (Operational) | -7 to 35 oC | |

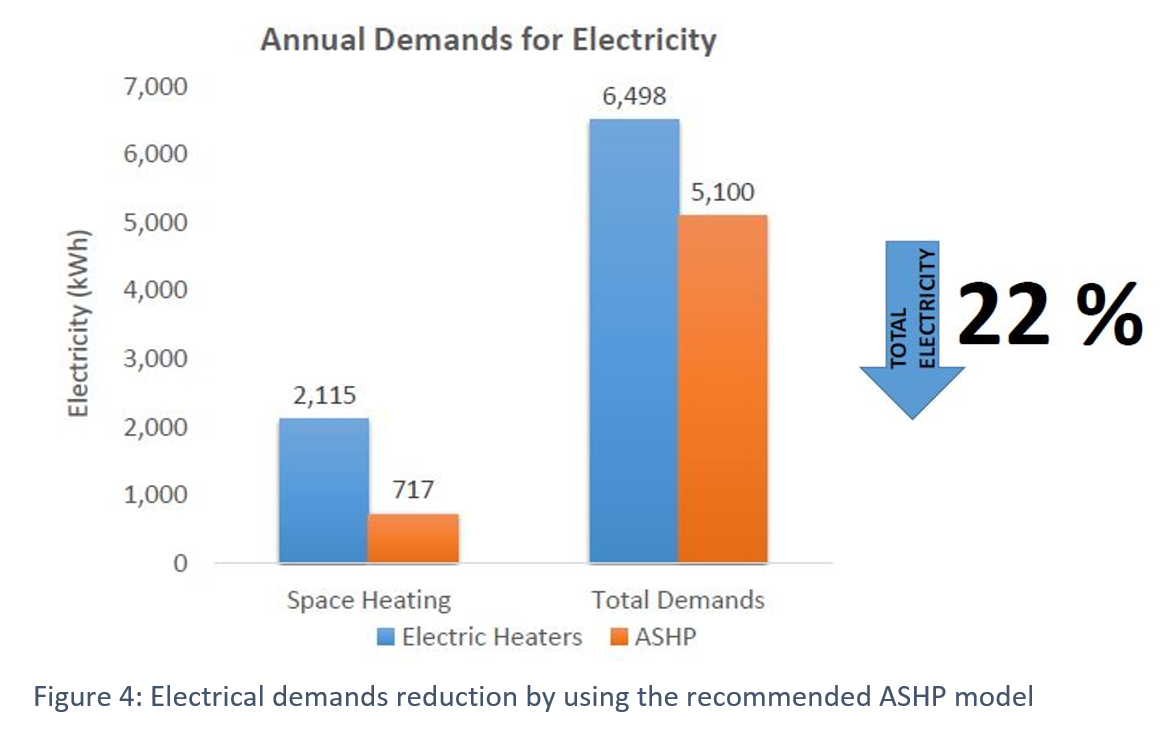

Having said that, it has been calculated that the annual demands for electricity in order to provide space heating using the ASHP were reduced from 2,115 to 717 kWh, thus by 2/3, in relation to the exclusive usage of electric heaters. Adding up to the rest of the electrical demands for equipment (4,383 kWh), we have achieved a total reduction from 6,498 to 5,100 kWh annually, hence by almost 22% (Figure 4).

Having said that, it has been calculated that the annual demands for electricity in order to provide space heating using the ASHP were reduced from 2,115 to 717 kWh, thus by 2/3, in relation to the exclusive usage of electric heaters. Adding up to the rest of the electrical demands for equipment (4,383 kWh), we have achieved a total reduction from 6,498 to 5,100 kWh annually, hence by almost 22% (Figure 4).

Advantages

- Relatively low installation cost and maintenance cost

- Income from the Renewable Heat Incentive (RHI) scheme

- Long life expectancy

- Generate more energy than they use

- Easier to install than Ground Source Heat Pumps (GSHP); no need for trenches or drilling

Disadvantages

- Less efficient than GSHPs

- Quoted COP data can differ from the design depending on the operating conditions, e.g. actual flow temperatures

- Surface area of underfloor heating and actual heating requirements can affect the system efficiency. However, at the BRE Visitor Centre this has been taken into account to achieve the optimum ASHP system efficiency.

Ground Source Heat Pump (GSHP)

A Ground Source Heat Pump (GSHP) uses pipes which are buried in the garden to extract heat from the ground. It circulates a mixture of water and antifreeze around a loop of pipe, called a ground loop. Heat from the ground is absorbed into the fluid and then passes through a heat exchanger into the heat pump. This heat can then be provided to the underfloor heating system. The ground stays at a fairly constant temperature under the surface, so the GSHP can be used throughout the year.

Our recommendation

We investigated the suitability of installing a GSHP and a WPF 5 kW (S) 232937 GSHP model, as shown in Figure 5. This can be commissioned to work in combination with the existing underfloor heating system for providing heat to the Visitor Centre.

It has been found that the underground temperature at 6 m depth in the UK remains relatively stable at 10 oC. The water temperature at the output has been considered at 35 oC, since the installed underfloor heating system is well-designed. In order to safely calculate the demands of the GSHP for electricity, we have used the COP value at B0/W35 (i.e. heat source temperature 0 oC, heat outlet temperature 35 oC), which is equal to 4.78 for the recommended model, as seen in Table 2. It is clear that the maximum output of the GSHP (5.88 kW) can cover the peak heating demands throughout the winter (up to 5 kW), under these circumstances. Back-up from electric heaters is unlikely to be used in this case, hence it was not incorporated in the study.

Figure 5: WPF 5 kW (S) 232937 GSHP

Figure 5: WPF 5 kW (S) 232937 GSHP

| Model Characteristics | WPF 5 (S) 232937 |

|---|---|

| Output at B0/W35 (EN 14511) | 5.88 kW |

| Power consumption at B0/W35 | 1.23 kW |

| COP at B0/W35 (EN 14511) | 4.78 |

| Dimensions (H/W/D) | 1319 / 598 / 658 mm |

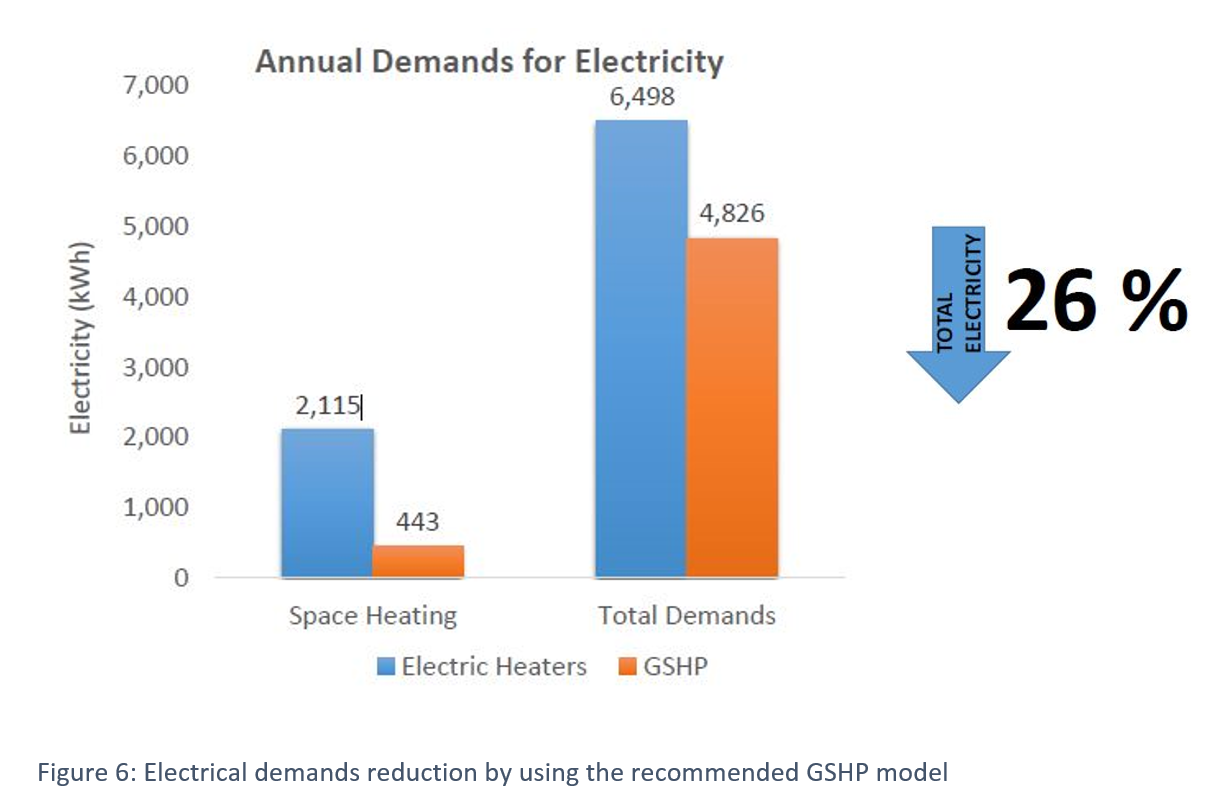

It has been estimated that the annual demands for electricity in order to provide space heating using the GSHP were reduced from 2,115 to 443 kWh, in relation to the exclusive usage of electric heaters. Adding up to the rest of the electrical demands for equipment (4,383 kWh), we have achieved a total reduction from 6,498 to 4,826 kWh annually, hence by almost 26% (Figure 6).

Advantages

- Low running cost and minimal maintenance requirements

- Income from the RHI scheme

- Safe; no combustion involved, no emission of potentially dangerous gases, no flues required.

- Low to zero carbon emissions

- Heat extracted from the ground is constantly being renewed naturally

- Silent; no planning permission required

Disadvantages

- High installation cost

- More difficult to install than ASHP

Biomass Boiler

Our recommendation

Lastly, we considered the installation of a biomass boiler, a wood-fueled heating system to work in combination with the existing underfloor heating system, as displayed in Figure 7. Specifically, we investigated on the installation of the BioWIN 102 biomass boiler model. Its characteristics are presented in Table 3.

Figure 7: Biomass boiler in combination with underfloor heating system

Figure 7: Biomass boiler in combination with underfloor heating system

| Model Characteristics | WPF 5 (S) 232937 |

|---|---|

| Rated thermal output range | 3.0 - 9.9 kW |

| Boiler efficiency at nominal load | 94.4 % |

| Power Consumption part load/nominal load | 16/28 W |

| Annual CO2 Emissions | 8 kg/m2 |

| Storage room dimensions | 2.5 x 1 x 2.3 m (5.5m3) |

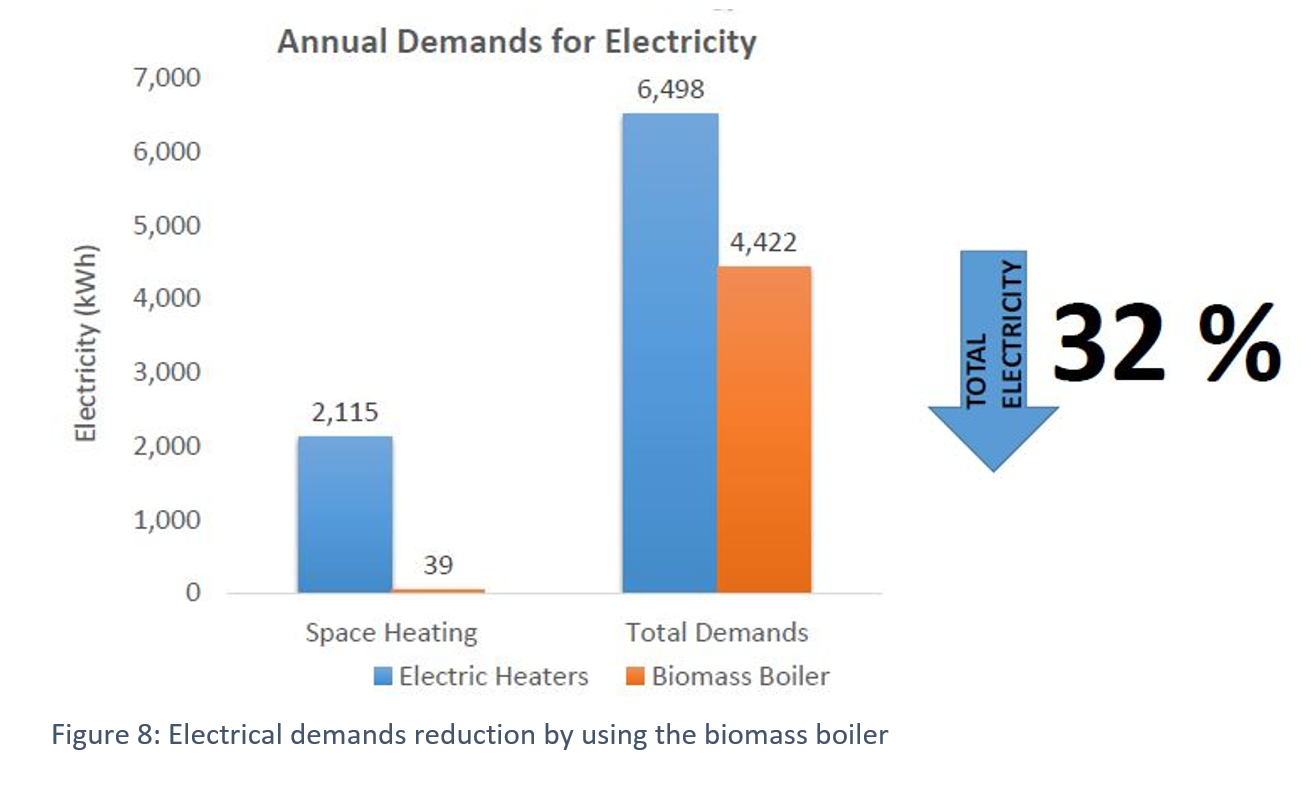

It has been estimated that nearly 0.5 tonne of wood pellets is required to cover the annual space heating demands for the Visitor Centre. The average wood pellet price of 4.34 p/kWh was incorporated in our financial analysis, while annual heating demands were considered to be eliminated by the biomass boiler. Therefore, the total electricity demands for space heating with the biomass boiler were estimated at only 39 kWh annually, according to its power consumption, as seen in Table 3, and the total heating hours. Adding up to the rest of the electrical demands for equipment (4,383 kWh), we have achieved a total reduction from 6,498 to 4,422 kWh annually, hence by almost 32% (Figure 8).

Advantages

- Low running cost and minimal maintenance requirements

- Income from the RHI scheme

- Reduction in heating bills

- Sustainable wood pellet fuel supply; not subject to price hikes

- Carbon neutral (if growing the biomass removes as much CO2 as is emitted into the atmosphere from its combustion)

Disadvantages

- High installation cost

- Higher maintenance cost than heat pumps; annual servicing required

- Space for fuel storage required

- Access for the delivery lorry for the fuel supply required