Materials & Technologies

It was important that the Visitor Centre, as the first building constructed on the site and home for BRE's staff on the Innovation Park, demonstrated very high levels of performance. It was, therefore, designed to meet BREEAM Outstanding at Design Stage. Every effort was made to align with this strategy during construction.

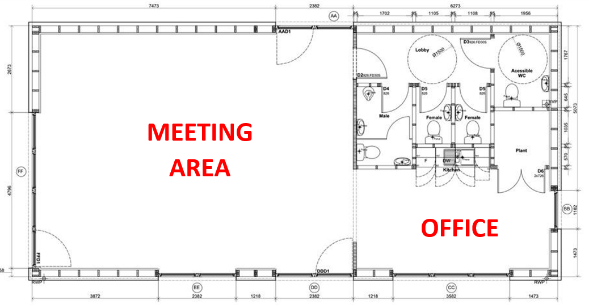

The Visitor Centre has a total area of 110 m2 with the meeting and office zones occupying an approximate area of 70 m2 and 20 m2 respectively.

Materials and technologies utilised in the Visitor Centre are presented below:

Triple glazing low-e Windows

| Layer | Description | Thickness (mm) | Absorptivity | Emissivity | Specific Heat (J/ kgK) |

|---|---|---|---|---|---|

| 1 | Low-e glass | 4 | 0.06 | 0.05 | 750 |

| 2 | Air Gap | 16 | (R=0.47 m2K/W) | 0 | |

| 3 | Low-e glass | 4 | 0.06 | 0.05 | 750 |

| 4 | Air Gap | 16 | (R=0.47 m2K/W) | 0 | |

| 5 | Low-e glass | 4 | 0.06 | 0.05 | 750 |

External Walls

| Layer | Description | Thickness (mm) | Conductivity (W/mK) | Specific Heat (J/ kgK) |

|---|---|---|---|---|

| External | Stone Panel | 10 | 2 | 753 |

| 2 | Air Gap | 100 | (R=0.17 m2K/W) | |

| 3 | OSB3 Board | 9 | 0.13 | 1700 |

| 4 | Blown glass mineral wool cavity wall

insulation (Supafil from Knauf) |

195 | 0.034 | 840 |

| 5 | OSB3 Board | 9 | 0.13 | 1700 |

| 6 | Air Gap (R=0.17 m2K/W) | 38 | (R=0.17 m2K/W) | |

| Internal | Fermacell Greenline gypsum fibreboard |

12.5 | 0.32 | 1100 |

CoolZone Ceilings

CoolZone ceiling tiles incorporate BASF Micronal phase change material (PCM) into Armstrong's plain metal ceiling tiles. The phase change material encased in the cassette stores and releases large amounts of energy, reducing cooling costs and maintaining a comfortable temperature within a building.

Mastertop Flooring System

The Mastertop Flooring System is a polyurethane and epoxy based resin which is suitable for decorative or industrial uses.

Lighting

| Lighting | ||

|---|---|---|

3 zones:

|

|

3 zones:

|

Mechanical Ventilation Heat Recovery (MVHR)

The MVHR (Nuaire MRXBox95 - WH1) is located in the plant room at the south east of the building and is installed in accordance with guidance in BRE Digest 398. It has a maximum performance of 110 l/s.

A total of six extract grilles for the system are located as follows: one in the lobby, four in the WC's (one in each) and one in the kitchen area. A total of seven supply diffusers are located in multi-use areas within the Visitor Centre; six in the main area and one in the smaller adjacent area. Each supply diffuser features a volume control damper to adjust the flow of air. The vents are currently set to run at 6 l/s in all areas of the building, except the kitchen, which runs at 8 l/s. The MVHR has a system efficiency of up to 95% (typical MVHR efficiencies vary between 90 - 95%); with a Specific Fan Power (SFP) of 0.4. The SFP is a measure of the electric power that is needed to drive a fan, relative to the amount of air that is circulated through the fan. It is not constant for a given fan, but changes with both air flow rate and fan pressure rise.

Solar Thermal Flat Plate Collector

A 3.3 m2 flat plate solar thermal collector (south facing, 30o tilt angle) is located on the roof of the Visitor Centre. The pump and control unit (Solar Logic Controller) are located in the plant room.

This is connected to a Willis Solasyphon heat exchanger, and is used to meet the domestic hot water (DHW) demand of the Visitor Centre.

Under-floor heating system

The under-floor heating system is capable of maintaining the desirable thermal comfort levels in the building zones, even at low outside ambient temperatures. The system includes full zone and temperature control.

Photovoltaics & Batteries

A 4.5 kW photovoltaic (PV) array (south facing, 30o tilt angle) is located on the roof of the Visitor Centre. This consists of 18 Suntech 250 W panels (STP250S - 20/Wd). The system features a Victron Energy Phoenix Inverter to convert the DC current produced by the panels to AC current. This can be used to meet the electrical load in the Visitor Centre.

The PV system also features a comprehensive battery facility for storing energy. This features:

- Outback Power Systems Flexmax 80 (FM80 - 150 VDC) Maximum Power Point Tracking (MPPT) Charge Controller;

- Victron Energy BMV 600S Battery Monitor;

- 6 x Surrette Battery Company Deep Cycle Series 5000 Batteries.

It is the purpose of the MPPT Charge Controller to sample the output of the PV array and apply the proper resistance (load) to obtain maximum power for any given environmental condition. The Charge Controller and Battery Monitor are located in the plant room.