THERMAL STORE OVERVIEW

The thermal storage tank selected is a direct thermal store, because it gives advantages over other options:

- 1. Less heat losses

- 2. Unfeasibility of a heat exchanger inside it (due to the big volume of storage required)

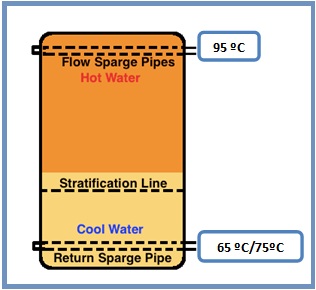

In order to optimise temperature stratification, sparge pipes will be used for water feeding and the boiler and the thermal store will be built independently.

The thermal store will be built on the ground for building simplification (it avoids interferences with underground water pipes and electricity network) and to reduce building costs.

SUPPLY AND RETURN TEMPERATURES

From similar case studies supply and return temperatures for the thermal store have been selected for the purpose of sizing the thermal store. It was decided that the supply temperature from the thermal store should be 95 degrees, while two return temperatures have been selected to allow for the unpredicatability of the return temperatures.

The two return temperatures selected are 65 and 75 degrees. These two return values to the bottom of the thermal store are based on the fact that, when the buildings are cold the return temperature can be significantly different from when the buildings have been heated for a number of hours. Therefore, two values for temperature difference have been taken into consideration in the analysis.

The value for the top temperature (95 degrees) has been selected from similar case studies and the bottom temperatures have been specified from this value and considering different thermal conditions in the buildings. Hence, the main information needed for the thermal store specification is as follow:

- 1. Water average Temperature: 80 degrees and 85 degrees

- 2. Density (80 C): 972 kg/m3

- 3. Density (85 C): 968 kg/m3

THERMAL STORE THICKNESS CALCULATION

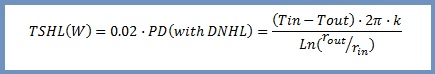

For the heat losses in the thermal store to be lower than 2%, the insulation thickness has been calculated using the formula below:

Being:

- 1. TSHL: Thermal Store Heat Losses

- 2. PD (with DNHL): Peak demand for the scenario including Distribution Network Heat Losses

- 3. Tin: Average temperature inside the thermal storage

- 4. Tout: Temperature outside (designed winter day: 0 C)

- 5. K: Insulation material conductivity (0.025 W/m2K)

- 6. rout and rin: Outside and Inside Ratios of the thermal store

The thickness is then:

References:

- Bard Skagestad, Peter Mildenstein. District Heating and Cooling Connection Handbook. Programme of Research, Development and Demonstration on District Heating and Cooling. International Energy Agency.

- Michel Y Haller, Eshagh Yazdanshenas, Elsa Andersen, Shris Bales, Wolfgang Streicher, Simon Furbo. (2010). A method to determine stratification efficiency of thermal energy storage processes independently from storage heat losses.

- Performance Specification for Thermal Stores. West Yorkshire: Hot Water Association Ltd.

- Rosen, M. A. (2001). The exergy of stratified thermal energy storages, Solar Energy.

- GreenSpec. (2012). GreenSpec Webpage. Obtained from http://www.greenspec.co.uk/thermal-storage.php

- Abdul Jabbar N. Khalifa, Ayad T. Mustafa, Farhan A. Khammas. (2011). Experimental study of temperature stratification in a thermal storage tank in the static mode for different aspect ratios. ARPN Journal of Engineering and Applied Sciences

- Ataer, O. E. Energy Storage Systems. Volume 1. Storage of thermal energy. Ankara: EOLSS.