Project Overview

Construction

Occupancy

Behavioural models

Demand

Renewable technologies

Conclusion

Team

Acknowledgements

Renewable Technologies

Matching options

After having completed the two major objectives of analysing the occupancy and creating the demand profile for a variable occupancy, it was time to look at the next objective of supplying options for our thermal and electrical demand.

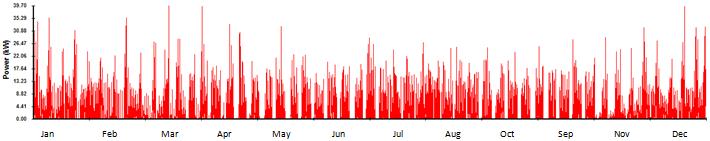

Thermal Demand Load Profile (24.25 MWh of annual consumption)

(Note that in winter, space heating is still running even the days with no occupancy; see space heating section for further details).

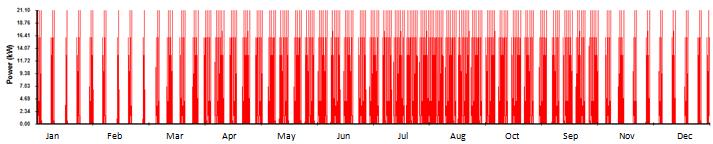

Electrical Demand Load Profile (22.70 MWh of annual consumption)

Merit software

Our simulated small-scale biomass CHP is based on a capacity of 50 kW (downdraft gasifier technology with modified diesel engine) with 1:1 heat to power ratio from Waste to Energy Ltd (Jones and Hogan, 2010). The main reason for choosing this small-scale biomass CHP is that its 1:1 heat to power ratio is the most suitable for our six houses energy demand (22.70 MWh for electricity and 24.25 MWh for thermal demand). Moreover, this biomass plant uses wood waste (wood chips or wood pellets) as fuel, which is relevant to our case study. Thermal efficiency and electrical efficiency needed to be assumed because the detail information of this small-scale biomass CHP could not be gathered. Hence we assumed that these efficiencies are 90% of the specified thermal and electrical outputs.

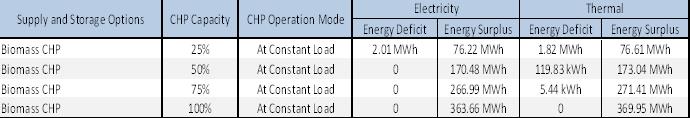

Because of the difficulties in finding the specifications for any commercially available small-scale biomass CHP from manufacturers (since most of their products are still in under research and development or in a patent protected stage) and with such a low capacity to supply only the first phase, we scaled down the 50 kW small-scale biomass CHP mentioned before, to operate at 25%, 50% and 75% of both thermal and electrical capacity output. Note that the heat to power ratio (1:1) and the efficiencies were kept as before. This method was used to find the different results from different sizes of the biomass CHP when supplying our thermal and electrical energy demand.

This table shows all the simulated small-scale biomass CHPs that we used in Merit Software.

Source: Jones and Hogan, 2010* (only for the electrical, thermal output and heat to power ratio)

All the plants were set to run at constant load over the one year period in this simulation instead of following the electrical or thermal demand due to the fact that CHP systems operate more efficiently when serving a constant load.

Thermal Demand (Hot Water and Space Heating)

The use of small-scale biomass CHPs results in a great amount of energy surplus, which, in order to achieve a Zero Carbon Community, should be used on site or be exported. We have to realise that, despite the capacity at which our biomass CHP are running, we will have surplus due to the fact that it runs at constant capacity and there will be some periods (i.e. during night and unoccupied) where the demand will be very low or none and hence the supply will be higher than required.

Electrical Demand (electrical appliances)

The above table also shows that the electrical energy surplus could not be avoided due to the variation of occupancy in the holiday houses. As for the electrical energy deficit, it could be solved by using different varieties of energy storage with other renewable technologies. For this particular site, the best option would be the use of PV panels with batteries.

Increasing the size of the CHP plants could solve the thermal and electrical energy deficit, however it would also dramatically increase the amount of thermal and electrical energy surplus.

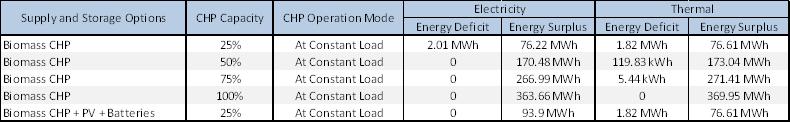

Biomass CHP + PVs + Batteries

Example of one solution comprises small-scale biomass CHP, 126 PV panels (21 PV panel per house installed as maximum) of 185W from ET solar (see solar section) and 30 215Ah@12V size batteries (5 batteries per house required to supply all the electricity demand). Batteries would only store the electricity from the PV panels in this simulation.

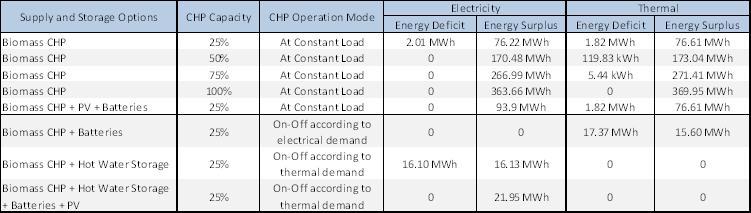

The following table compares the results between the demand-supply matching of the small-scale biomass CHP with and without PV panels + batteries.

This (biomass CHP + PVs + Batteries) option would be better, because it has no electrical energy deficit, which means that it can supply all the electrical demand needed in this case study. Moreover, it has less electrical energy surplus than that other operating capacity. This solution is just one of the many ways that could be solved the electrical energy deficit problem. When there is energy surplus, we could use electric hydro pumps to supply water to a reservoir that would be installed on top of the nearby hill. During periods of high electrical demand, the stored water would be released through turbines to generate electricity. It would be used as an energy storage system to meet the high peak electrical demand throughout the year. Flywheels or compressed air should also be investigated further to find the optimum solution.

Biomass CHP at On-Off Operation Mode

Another possible solution would be to operate the output capacity of the CHP according to the occupancy level. But, even using this solution, we would still have thermal energy surplus as well as thermal energy deficit. Moreover, having a look to the thermal and electrical demand profiles, we can realise that it would be difficult to set the optimum capacity at which the Biomass CHP plant should operate in each moment. The table below shows example solutions and combinations to be used with On-Off operation mode biomass CHP.

Biomass CHP has been operated into two operation modes. Firstly, biomass CHP is turned on and off according to electrical demand load profile. The electricity would be stored in batteries (17 215Ah@12V batteries) before supplying the six houses. CHP will be turned off when the batteries are fully charged. This operation would not have electrical energy deficit and surplus. However, there is huge amount of thermal energy deficit and surplus. CHP needs to be turned on and off approximately 400 times per year due to the variable occupancy in these six houses, which would shorten the life-time of the CHP plant. If biomass CHP has to be operated this way, hot water storage tank can be used to reduce the amount of thermal energy deficit and surplus. The size and specification of hot water storage should also be investigated more in details.

Secondly, biomass CHP is turned on and off according to thermal demand load profile. With similar principle to previous mode, heat would be stored in hot water storages (10 m3) before supplying to six houses. CHP will be turned off when the hot water storage tanks reach its maximum temperature (70°C in our simulation). This operation would not have thermal energy deficit and surplus. And there are huge amount of electrical energy deficit and surplus. The number of times that CHP need to be turned on and off are about 200 times per year.

These two operation modes are suitable for only electrical or thermal demand. Following only electrical or thermal demand would not be suitable for other because both of the demands are not occurring at exactly same time.

Example of one solution for on-off operation mode following thermal demand comprises biomass CHP, hot water storage, batteries and PV. In order to be able to supply 100 percent of electrical demand, PV have to be installed covering all the south facing roof space for six houses with 21 batteries for each house. The problem is still with huge amount of energy surplus similar to previous solutions.