Once biogas was considered the most promising method of getting energy from the waste stream, there was a need to try to sort out the best method of applying it to the community. There are numerous factors that can affect the rate and amount of biogas a digester produces, some of which are listed below.

• Type of digester

• Temperature of the process

• Retention time of the organic mater

• The PH of the system

• The amount of mixing

• The types of bacteria present

• The presence or lack of various chemicals in the substrate

It became apparent that different substrates (inputs) require different approaches. Heating was beneficial because it sped up the process; however, high temperatures for a fast thermophilic process can be difficult to maintain if there is a lot of water in the substrate. There was a need for a reasonable output from the system, along with a reasonably short retention time, for the waste in the bio digester to ensure that the system wasn’t too big. This resulted in a mesophilic bio digester from Zorg biogas being selected for the Dalmarnock plant that had an operating temperature of 36-38 degrees Celsius. It is possible to maintain using the heat from a cogeneration (CHP) system that will burn the methane. For the bio digester, it was assumed that a 100tonne per day digester could be built and the costing was estimated accordingly. For Dalmarnock, the original intention was to use sewage as the main feedstock for the digester, but it quickly became apparent that the energy content of waste food is considerably higher. Therefore, it needed to be considered as an important source of the energy needed to make the system work.

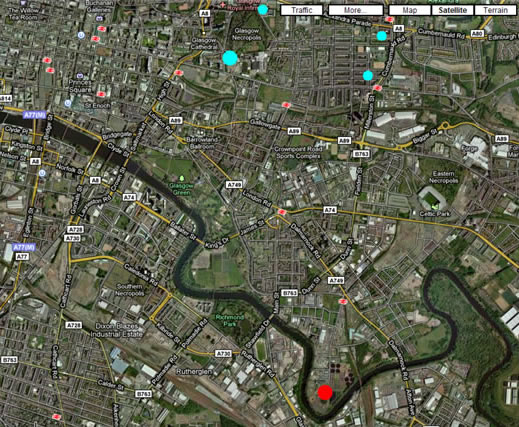

Figure 1 shows the likely position of the biogas plant, it will be dealing with the waste food and sewage from the 250000 people it serves and is proposed that it will be at the sewage works. This is to ensure that there is a minimal amount of transportation of the human waste, which has a lower calorific value. It will also eliminate any concerns over planning permission for a new site

Figure 1 The position of the Dalmarnock biogas plant marked in red and the Dennistoun area marked in blue

Despite the large potential in using food waste, it is not without its challenges, most of which involve collecting a pure waste that can be put in the digester. There can be problems associated with plastic clogging the digester system and, although sorting the waste removes most of the plastic, the sorting process can result in a substantial loss of the organic fraction of the waste. A method, used in Denmark to deal with this problem, is to introduce an organic bin to each household (source separation) and encourage people to collect their kitchen waste in paper or starch bags. Grinstead, a biogas system in The Netherlands, introduced this system of collection and found that it resulted in the loss of only 1% of the organic fraction of the municipal waste stream. This is a substantially better performance than the systems that tried to separate the different types of waste after they were collected. Some of these systems resulted in a 45% loss of the organic waste and, as a result, a lot of the systems that did not use source separation failed to make a profit. There also appeared to be a significant cost associated with transporting the waste long distances, this is why the local sewage works is considered in this project.

In the Netherlands, the use of source separation produces substantial improvements to the efficiency of the system and because of this; it appears an attractive option to be encouraged. This is despite the fact that it requires a certain amount of extra effort from the general public to sort their waste. However, a report commissioned by Glasgow city council, indicates that they would expect the cost of collecting food waste separately from other waste streams to be quite substantial. This is because of the separation of food waste from other rubbish may be unpopular in the tenement flats that make up most of Glasgow’s housing. Glasgow city council is currently proposing a system that involves separating the waste after collection. However, it was decided that this project would use source separation as this would decrease the amount of contamination in the resulting digestate, which would mean it would be more desirable as a fertiliser.

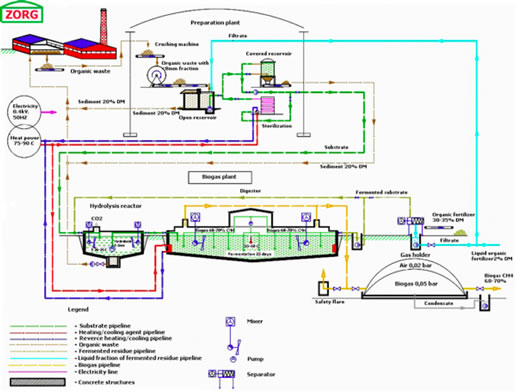

Figure 2 diagram of the biogas plant for using food waste

The source information used for sizing the biogas systems was a company called Zorg biogas. They have extensive information about their systems available and they were selected to be the theoretical suppliers of the biogas equipment at Dalmarnock sewage works. Their information was used for costing and sizing the plant according to the amount of waste there was to available to it. It was decided that the resulting digestate from the digester can then be treated as sludge and sent to the sewage drying and pelletisation plant at Daldowie through the pipe that is used to connect Glasgow’s major sewage works together. The proposed plant will take up an area of 5600m2 and an inspection of the sewage works indicated this system could fit in the area highlighted. Another proposal could be to position the plant on the other side of the railway lines..

Figure 3 The Dalamrnock sewage works with an area representing the biodigester

The pellets that are produced at Daldowie are currently used as waste derived fuel (WDF) and mixed in with coal and burned at Longannet power station. Because of the low concentration of the pellets used, their effect is considered to be negligible and are considered having the same calorific properties as brown coal. However, anaerobic digestion will reduce the amount of combustible solids available in the sludge pellets that will result in it becoming a poorer quality fuel. This may affect the desire of power stations to consider using sludge pellets and further studies would be needed to consider this.

Substrate Biogas Production |

m3/tonne |

Faceses |

24.0 |

Organic Waste |

190.0 |

Table 1: Biogas Production Assumptions