Challenges with large scale retrofit

As with any energy system, there are going to be sizable challenges if there is to be a shift towards large scale building retrofit. The current approach towards a more sustainable and decarbonised energy grid is to focus on low carbon generation, such as wind, hydro and carbon capture and storage. These will always play a vital role in a lower carbon future, however large scale retrofit (and more specifically deep retrofit) take a different approach, so will present unique challenges.

These challenges can be separated into 4 categories, and all of these present barriers to large scale retrofit and will require development to increase the feasibility of a large scale retrofit scheme. Here are details of each of these factors:

These challenges can be separated into 4 categories, and all of these present barriers to large scale retrofit and will require development to increase the feasibility of a large scale retrofit scheme. Here are details of each of these factors:

|

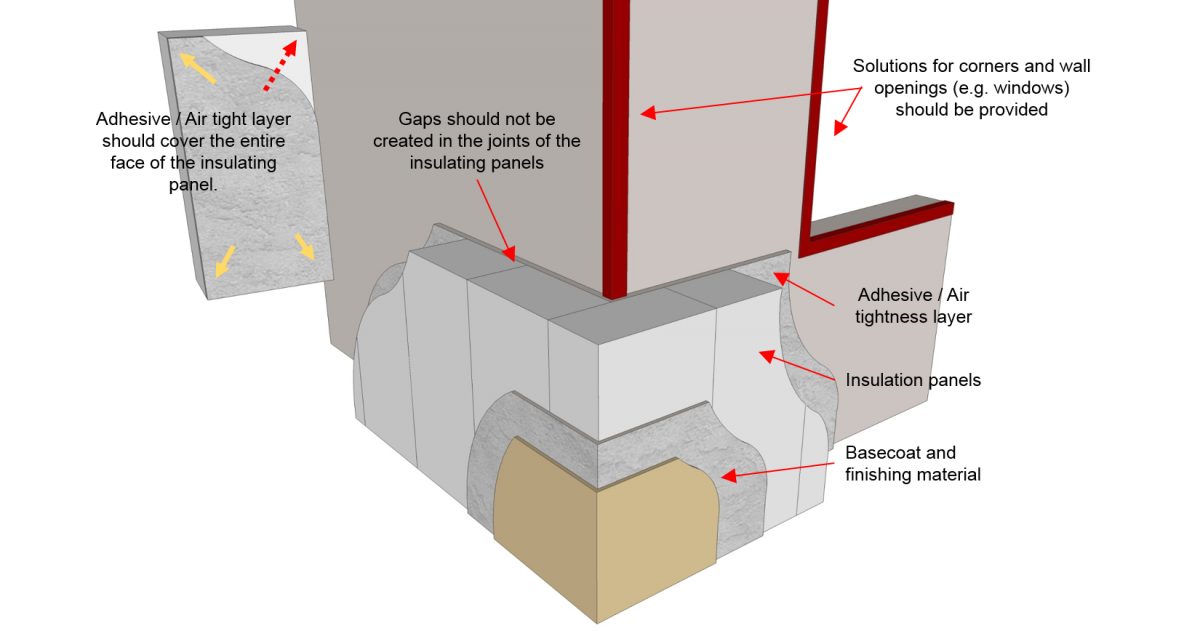

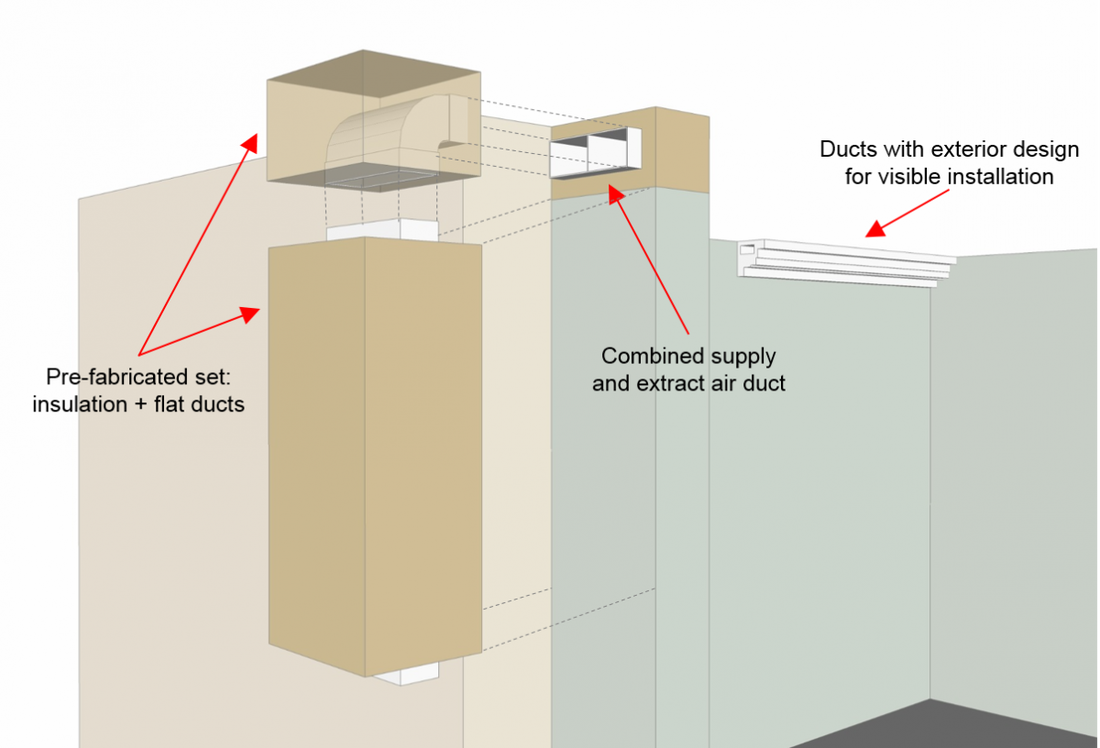

Technical This aspect is all to do with how the retrofit measures could actually be implemented into buildings. Examples of this are the ventilation ducts as part of the MVHR system which need to be routed in the existing building and another is the challenge of thermal bridges and minimising them wherever possible. To deploy retrofit on a large scale, would require the construction and building services industries to innovate products and processes to tackle the technical challenges of implementing the measures. One initiative focussing on delivering large scale deep retrofits at a large scale is EuroPHit. They suggest the use of the step-by-step method and have identified a number of products which development should be focussed on, shown here. From the retrofits that have been executed under this scheme, a number of issues have been identified and EuroPHit has specified design briefs for a number of product ideas which industry could then aim to bring to production. Examples shown below are the "External air-tightening, insulation and finishing system" (EAIFS). This product would mean that retrofitting of walls could be completed in one process. The other example shown is ventilation ducts suitable for visible installation, which would increase the feasibility of MVHR systems. |

|

Occupant management

Ensuring that occupants have the best possible experience before, during and after the retrofit is a key part of making large scale feasible. Since this would be a particularly invasive approach compared to large scale generation, public acceptance is a vital part to large scale retrofit. One aspect of this is to reduce the timescale of retrofits from a number of months to a number of weeks. To do this, processes would need to be innovated as described above. Also, disruption should be minimised as much as possible. A number of previous retrofits, including some of the Retrofit for the Future projects, involved the occupants being relocated during the retrofit. Relocation could be managed as part of the retrofit process, however this may face significant resistance, particularly from private housing, which makes up the majority of the housing market. To improve the experience after the retrofit process, a well thought over handover process is a necessity. The book "Residential Retrofit: 20 Case Studies" highlights the positive response from properties which generated a user manual for the occupants after the retrofit. Also, well designed and simple controls are required, as highlighted in the Retrofit Challenge paper. These two aspects should be integrated into the retrofit design process from the start and will ensure that occupants have the best experience after the retrofit, further enhancing the public acceptance of the large scale retrofit. |

|

Performance Guarantee

Monitoring results showed that many of the Retrofit for the Future projects did not perform as designed, referred to as the performance gap. The Retrofit challenges paper discussed this as a key difficulty and is describes as a two-fold problem: prediction and delivery. Prediction is related to differences in the material performance (e.g. thermal conductivity of insulation) and delivery is errors with the installation of measures. Issues with either will result is a performance gap. It's most likely that errors will occur in the installation, since modelling often assumes measures are installed perfectly. This is particularly true if the contractors are inexperienced with this type of work, as was the case with Retrofit for the Future. The report suggests that systematic work should be undertaken to close this performance gap by improving understanding of the link between the process and building performance |

|

Costs

All the Retrofit for the Future cases had final costs which would make large scale retrofit unfeasible. This is mainly due to the fact that these builds were performed on an individual basis. To make large scale deep retrofit financially feasible, there is a requirement to have significantly cheaper retrofits. This will occur due to economies of scale, however there is also a requirement for the industry to innovate in product and process to allow further reductions in cost. |

Changes in Industry

The overall findings from papers considering the large scale retrofit are that there needs to be a significant shift in the approach of the construction industry. All the challenges outlined above can in part be tackled by a more industrial approach to manufacture, specifically offsite manufacturing. This can simplify the installation phase, reducing disruption and reducing timescales, while also having the benefits of a more controlled construction environment improving quality and on top if this lower construction costs.

This should also be combined with the more scientific approach of building physics in the design phase as well as integrated monitoring and controls to maximise performance during operation.