Phase Change Material Methodology

The addition of phase change materials in buildings can have many benefits such as possibly reducing heating loads, enhancing occupant comfort and possibly reducing energy costs. They also have very flexible applications and can be utilized in plaster (Gypsum, Cement etc), boards for dry wall construction, Ceiling tiles, PUR-coatings etc . The PCM's were tested using ESP-r. Firstly, simulations were run for the base base model and the results from this were to be used as a control to test any changes in energy consumption caused by the integration of PCM's.

In order to simulate a phase change material on ESP-r a special component file must be created and then the user must choose at which material and which node within the facade wall the PCM is to be located. PCMs currently have a range of operational temperatures which can range from sub zero temperatures to hundreds of degrees Celsius. PCM's in buildings tend to have operational temperatures from 18-30 degrees Celsius. For our investigation we decided to run simulations for 3 different PCM's with switching temperatures of 21,23 and 26 degrees. This would allow a comparison to be made between which switching temperature was most effective and reduced energy loads the most.

There are several numerical values required in order to model a phase change material using ESP-r and these are, melting temperature, solidification temperature, conductivity in solid phase, conductivity in liquid phase, specific heat capacity, latent heat a and latent heat b. Most of these values can be acquired from PCM manufacturers and for the sake of this study we used values from the German company Rubitherm ( http://www.rubitherm.de/english/index.htm ) .

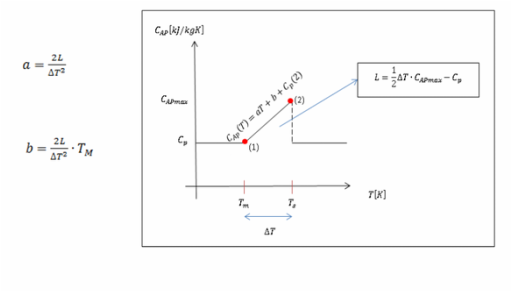

The only value which had to be calculated was the latent heat a and b values.

In order to simulate a phase change material on ESP-r a special component file must be created and then the user must choose at which material and which node within the facade wall the PCM is to be located. PCMs currently have a range of operational temperatures which can range from sub zero temperatures to hundreds of degrees Celsius. PCM's in buildings tend to have operational temperatures from 18-30 degrees Celsius. For our investigation we decided to run simulations for 3 different PCM's with switching temperatures of 21,23 and 26 degrees. This would allow a comparison to be made between which switching temperature was most effective and reduced energy loads the most.

There are several numerical values required in order to model a phase change material using ESP-r and these are, melting temperature, solidification temperature, conductivity in solid phase, conductivity in liquid phase, specific heat capacity, latent heat a and latent heat b. Most of these values can be acquired from PCM manufacturers and for the sake of this study we used values from the German company Rubitherm ( http://www.rubitherm.de/english/index.htm ) .

The only value which had to be calculated was the latent heat a and b values.

Latent heat values can be calculated using the above graph and the associated equations. The graph shows the equation of the line between the melting and solidification temperatures and heat storage capacity. By substituting the equation for L into the equation for C(ap) it is possible to determine values for a and b. These values were then used in conjunction with the data gathered from Rubitherm to input the PCMs into ESP-r. For a step-by-step procedural guide of how this is done, click the link below.

| esp-r_phase_change_material_modelling_procedures.pdf | |

| File Size: | 1038 kb |

| File Type: | |