Small Scale Hydro: Novel Approaches to Generation & Transmission

Transmission Conclusions

Considering the financial challenges of any upgrade for distribution and transmission, we believe that the idea of running cables through supply tunnels such as the one in Glen Almond may work but only if delivery & installation costs are comparable to the costs of under-grounding a cable. At April 2010 prices, the overall price per km for sub-sea cabling is approximately £165,000 indicating that, for the tunnel option to be viable, cost of transporting and installing the cable should not exceed £65,000 per km.

The tunnel owners would have to agree a method statement and regime for the installation, fixing and maintenance of the cable.

Sub-sea power cable is designed for use in harsh environments. Though there is the potential for erosion and corrosion, the lack of salt water & relatively low water speeds give the potential for a long life of installed cable.

Further areas of work:

There are some areas we feel would benefit from further investigation:

The laying of sub-sea cables through tunnels - Draw up a methodology in conjunction with the owners of non pressurised tunnels to agree access arrangements and a continuation and enhancement of the CFD model form 2-D to 3-D.

Logistic of moving the large and heavy sub-sea electrical cable - From the factory to site, the choice of supplier would play significant part in the overall cost. Should this project be progressed, the cost of delivery to site is a significant factor due to the locations of the manufacturing facilities. If there was potential for schemes in the southern part of the British mainland for example, then the Italian factory may be more cost effective than from the Scandinavian located factories. Scandinavian countries would be more suitable for any projects developed in the northern half of the country.

Generation Conclusions

The main conclusions which can be drawn from our investigations concerning generation and transmission when considering the introduction of Feed-in Tariffs are:

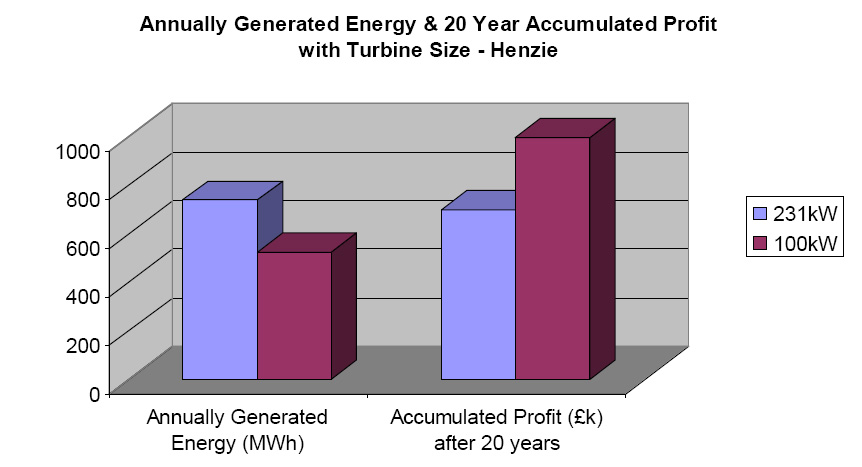

1.Sizing a scheme to extract the maximum amount of energy over a year may not necessarily result in the maximum profit over a 20 year period. We have shown, using HydroCalc2010 (our excel based hydro scheme calculator), that in some instances, downsizing a scheme by using a smaller turbine can qualify the scheme for a higher tariff rate, reduce capital costs, and result in a greater accumulated profit over the 20 year period the tariff is guaranteed for. It would seem prudent therefore to size a scheme for maximum energy generation and also for a smaller scheme in the next highest tariff band in order to compare the two before deciding on how to proceed. Evidence to support this is summarised in the chart below.

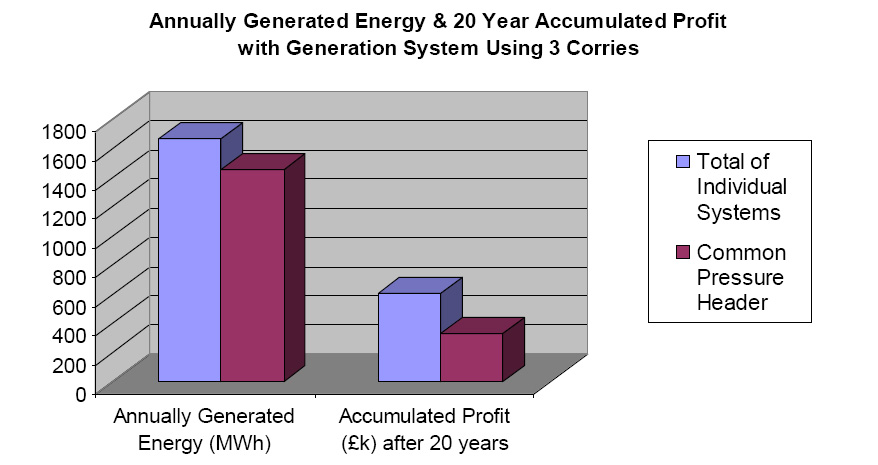

2.Where multiple water courses of variable flow exist in relatively close proximity, it is more beneficial to keep the generating systems separate, e.g. each water course feeds a pipeline leading to a single turbine, than it is to combine the flows in a pipe network leading to a large single turbine equivalent to the sum of the individual turbine systems. This is because a large single turbine cannot generate as efficiently over the lower flow ranges as the individual systems and the total generated energy over a year is less, so although capital expenditure is greatly reduced, accumulated profit after 20 years is less. Evidence to support this is summarised in the chart below.

Project Deliverables

Here are the tools produced for help in sizing and implementing a small scale hydro scheme

Hydro Calculator Tool in Excel 2003 format and Excel 2007 format

Small Scale Hydro Calculator Tool User Guide(PDF)