The power value used in the above equation is the max power required instantaneously by the two zones in the period assessed as noticed in ESP-r cooling results.

As the flow rate is v=0.087m3/s and the cross section area is equal to 0.0078m2 the required velocity of the air through the pipes is 11m/s.

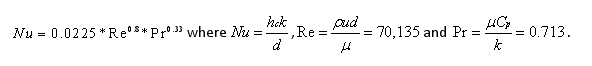

For the estimation of the convection coefficient we have used the following equation:

From the above the convection coefficient is: hc=39.76W/m2K.

The sizing of our system and optimum values regarding air flow rate and velocity where influenced by similar cases in literature relating to climatic conditions and system magnitude, power consumption and thermal load output.

Thermal COP values

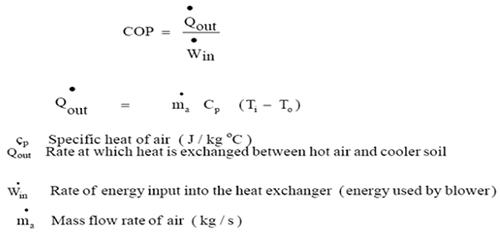

Coefficient of performance is a measure of heat exchanger efficiency. It is defined as (ASHRAE 1985). COP values mentioned bellow regard the energy output to input ratio. Input values are the energy consumed by the blower (300W) and output energy is the cooling or heating thermal energy introduced in a building.

Ventilation

◊ Mechanical Ventilation can be managed through a terminus box ('plenum') and be fan powered or individually fan assisted by installing a 10 cm axial fan in the end of each tube in case of more tubes than one. At day time ventilation could be powered by a PV system located upon the roof.

In our case we have considered a similar system with prof Sharan's report (5) utilising a 400W rated ventilator. Actual energy consumption for a mass flow of approximately 0.1 m3/s and an air velocity of 11 m/s would add up to rouhly 300Wh per hour.

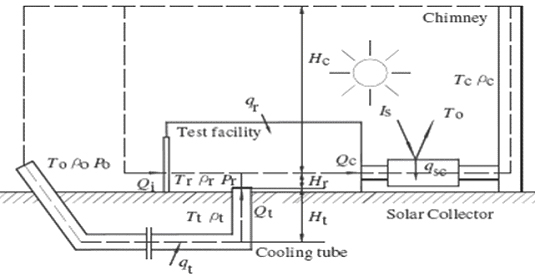

◊ Passive ventilation Passive ventilation through the combination of a solar chimney and solar panels is an alternative to a fan. A solar chimney could be connected to solar panels (heating air) on ground level increasing air temperature inside the base of the chimney. This would lead to air mass expanding and creating a draft through the chimney due to pressure difference. Negative pressure would be created and if well sealed the pressure difference would result in passive ventilation due to air pulled through the buried pipe at an adequate flow rate. Low infiltration from walls and openings has been considered as well as friction reducing the flow rates and has been deducted from the chimney flow rate in order to estimate that of the buried pipe.

Link to our model

Our ESP-r earth to air heat exchange model (located in Palermo) had similar specifications and climatic conditions with the report of the University of Nebraska (7). Specifically similar values where considered concerning pipe air flow, ground temperatures-depth, local climatic conditions, leading to a natural air flow of 0.13 m3/s (afternoon hours) in the solar chimney. This was 0.043m3/s more than the requirement (0.087 m3/s) of our model. Concerning the summer period, deducting a minimum flow of 0.012 m3/s (infiltration rate of the dwelling structure) from the chimney's flow could replace an energy equivalent (due to the fan's reduced operation) of:

3(months)*10 (daylight hours)*0.3 (kW power) = 276kWh. Unfortunately, the 20m2 solar collector area reported in literature (7) in combination with certainties regarding necessary pressure differences, complexities due to friction in the buried pipes and the fact that this system was only functional for daylight hours discouraged further evaluation of this scenario.

Conclusions

The efficiency values we were expecting for Southern Europe were compared to Baxter's facility at Knoxville, Tennessee (USA) which was consisted of a similar sized pipe, climatic conditions and site latitude. Specifically the mean hourly values for the entire period of test ranged from COP= 1.4 to 2.69. During these periods basic soil temperature varied from 14.8°C to 18.2°C. Using the above COP equation and considering our flow rate, an average pipe outlet temp of 19°C and an average inlet in summer of 25°C the estimated COP value is roughly 2.1. ESP-r results agree for the 10:00-19:00 hour (COP=2) decreasing to a value of 1.6 when operating all day, as during the night temperature differences decrease considerably.

|