Barony College Technology Recommendations

| Suppliers |

Once the demand has been quantified and a fuel type decided on, the task of selecting the technology to be used can be undertaken. The different types of available technology are vast and wide-ranging but when scale and fuel type are taken into account the search for suitable technology tends to narrow itself down.

In the case of the Barony College it has been shown in the previous stages that the most suitable fuel supply, at least in the short to medium term is wood chip, although it is worth noting that this may not always be the case and therefore there may be some merit in considering technology which has a little flexibility on this front.

The heating demand for an average winter day at Barony College is around 260kW with a peak value of 630kW while the peak hot water demand is 100kW with a daily average value of 12kW. While hot water is required all year round, heating will only be needed in the cold part of the year, from about October to April.

System Recommendation

Given the demand requirements and fuel availability it is possible to make a specific recommendation for the best kind of system to heat the college campus. The basis of this recommendation is that the 335kW industrial oil boiler, which currently heats the old building, should be retained and a new woodchip burning biomass boiler with a thermal power output of about 350kW installed. When installed with a hot water accumulator tank this bivalent system would have availability between 99.5-99.9%.

The reasoning behind this decision is twofold. Firstly a woodchip boiler of this size would be well suited to meeting the average heating demand of the college through the colder months from October to April. Secondly, the current oil system provides an ideal backup, which would be capable of supplementing the woodchip boiler on winter days, and also able to supply the hot water demand during the warmer months when the woodchip system could be shut down. The effect of this would be that 99% of the college’s heating would be supplied from burning woodchip.

The different components that must be installed for this kind of system can be separated into two different areas: Those which will be supplied by the boiler supplier, and those which must be constructed or sourced from a third party. Generally three of the main components come from the boiler manufacturer via a supplier, these are:

• The actual boiler system

• Fuel feed system

• Hot water accumulator

However before considering this the other important components must be identified and sourced. In this case, and as a general rule these are:

• Boiler House

• Fuel Storage

• Additional Plumbing

Boiler House & Fuel Store

Barony College have indicated their intention to have the boiler housed in a new building across from the workshop on campus. This gives an opportunity to design a building that can accommodate a simple and effective fuel feed system and give easy access to the fuel storage at the same time.

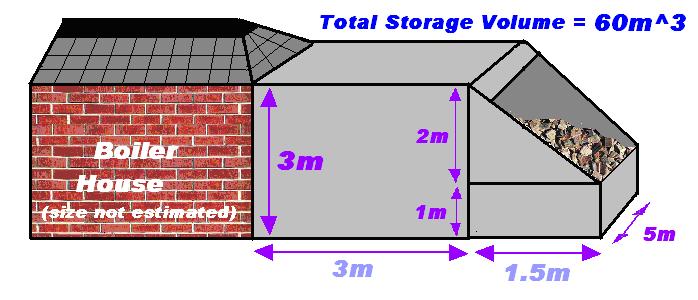

Based on calculations undertaken as part of the local supply analysis it was estimated that a volume of 2.99m3 of woodchips would be required daily during the heating season (Oct – March) to satisfy demand. Therefore if a 7.5 tonne truck was utilised, with 30m3 volume, one delivery would last ten days. In order to ensure a safety margin of ten days fuel, in case of a supply failure, a 60m3 fuel store is required.

It was also decided that since space has been made available to construct a boiler house and fuel store, on the site currently occupied by the portacabins, it would make sense that both buildings should be situated adjacent to one another. This would allow direct feeding of fuel to the combustion system. This can be performed by a moving floor device, of which an 8mx5m model has been sourced.

With these two factors in mind a possible design for the fuel store is shown below: -

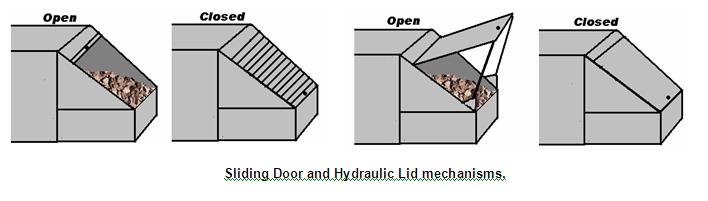

Building to the specifications given would give a total fuel storage area of 60m3. The sloping front area, just one metre high, would allow for direct fuel deposition from a lorry. In order to close off the loading area, and therefore stop contaminants/additional moisture entering, two methods are postulated. These are shown below: -

The left hand diagram shows a sliding door mechanism, such as might be found in a garage. While the second is a hydraulic lifting lid (as used in North Lanarkshire). Ensuring direct loading from the lorry obviously leads to cost savings associated with the time required to manually load fuel.

Extra Plumbing

With most suppliers, their installation of the boiler only involves the boiler components and the electrics involved. Any extra plumbing which may be required, such as connecting the heating system in the buildings to the boiler in this case, must be carried out by a third party.

Suppliers

It is necessary to identify suitable UK woodchip boiler suppliers to supply the necessary equipment such as the boiler system itself, a fuel feed system and additional components like a hot water accumulator tank. This recommendation includes two suitable suppliers: Highland Wood Energy in Fort William and 3G Energi in Kelso. Both these suppliers offer a comprehensive supply, install & maintain service lasting throughout the boilers lifetime.

Boiler Systems

Highland Wood Energy

Fröling Turbomat 320

The Fröling Turbomat is a fully automatic wood burning boiler which

can burn a wide range of wooden material, and automatically controls fuel

feed, combustion and ash removal.

Rated Power Output: 320kWth

Size (mm): L=3250, B=2500, H=2440

Cost: £80,000 installed (including electrics and control system)

3G Energi Ltd

Kob Pyrtec 350

The Kob Pyrtec is a traditional underfed stoker type of boiler with an

excellent control system and automatic ignition as standard. There is

also an option for de-ashing to wheelie bins.

Power Output: 250-360kWth

Size (mm): L=2389, B=1110, H=1980

Cost: £100,000 installed (including electrics and control system)

Fuel Feed System

Given the boiler housing and fuel storage configuration there are a number of different methods that could be used to transport the woodchips from the fuel store to the boiler.

For the Kob system from 3G Energi the best option for a fuel feed is to fit the storage unit with a moving floor which would transport the fuel directly from the store to the boilers feed mechanism as shown in the diagram.

The recommendation for the Fröling Turbomat system is a spring agitator type feed system, again providing means to transport the fuel from the fuel store to the adjacent boiler house.

Hot Water Accumulator

A major problem associated to woodchip boilers is that their response to a fluctuating heat load is not as fast as that of an oil/gas fired boiler. The heat load may indeed vary very quickly due to peak hot water requirements (showers, cooking): a woodchip boiler alone may not be able to respond in time and the temperature of the “hot” water might drop very significantly.

The solution is to use a hot water storage unit (an accumulator) which would act as a buffer between the boiler and the demand-side requirements. If the heat load happens to peak, the temperature of the water in the accumulator would decrease sufficiently slowly to let the biomass boiler reach rated power in time.

It is likely that an accumulator tank capacity of around 1000 litres would be required and this is included in the installed cost of both systems.

Clarify

Standpoint of Organisation |

Quantify

Demand Requirements |

Assess

Potential Biomass Supply within Local Area |

Match

Demand & Fuel Supply to Available/Suitable Technologies |

Check

Relevant Legislation |

Apply

for Funding |