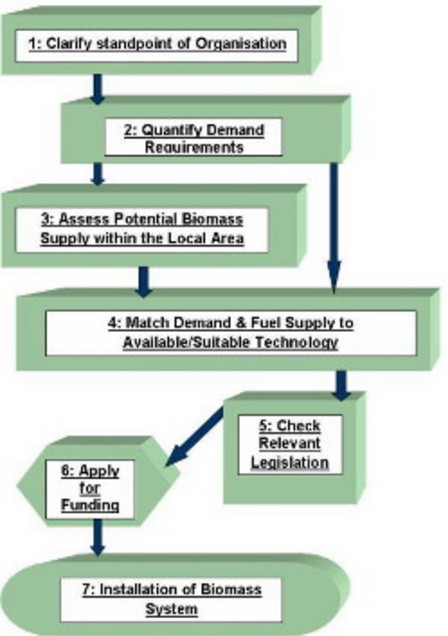

Biomass Feasibility Assessment Schematic

Introduction

The following schematic diagram outlines a generic flow-path which should bring together all the relevant activities an organisation is required to undertake when initiating a biomass heat/power/CHP project. The proposal suggested, although developed for high demand public sector/academic buildings, has the potential to be utilised by any individual or organisation. From householders, SME’s to Local Authorities.

Given due consideration to each of the factors detailed within the schematic, in the set order, will lead to a systematic approach to assessing if biomass has the ability to meet the requirements of the organisation in question. Potential problems which may be encountered, such as matching supply & demand and identifying the correct technologies etc, will be mitigated through taking this logical approach.

The relevance of each stage in the assessment will be outlined alongside some essential activities which should be completed before advancing the project (check boxes).

To find out more information on each section click on the diagram corresponding to the section of interest.

1. Clarify Standpoint of Organisation:

Why Important: Before committing to undertaking a biomass project considering the following aspects may be useful: -

• The current heating system in place. What are its limitations, does it need to be replaced due to age, environmental policy or high running costs. Will biomass fuel rectify these drawbacks?

• If there support for utilising biomass within the organisation. Committing to utilising biomass fuel will be more complex than a straight ‘like for like’ replacement system.

• What budget is available for the system; will grant funding be required?

• Are there necessary skills present within the organisation to undertake the project or will external assistance, i.e. a consultant, be required?

Check Boxes:

| Is there support for using biomass? | |

| Are the reasons for considering biomass well defined? | |

| Has a budget been set? | |

| Are there the necessary skills within the organisation to complete the project? | |

| Has contact been made with relevant organisations? |

2. Quantify Demand Requirements:

Why Important: Calculating demand can be conducted through direct calculations of UA Coefficients. Should this not be possible assessing current demand within the building will allow specification of the size of the system required (as long as the current heating system is not undersized and incapable of meeting demand).

Correct sizing will ensure the system can cope when demand is at a maximum, i.e. coldest winter day, and also ensure maximum efficiency i.e. that the system is not operating at part load for extended periods. Quantifying demand is also essential in establishing the quantity of biomass fuel supply required; an essential factor in discussions with potential suppliers.

Check Boxes:

| Demand profiles collected i.e. summer/winter, daily | |

| Final size of system required (in kW) quantified | |

| Electricity to heat demand ratio established | |

| Demand reduction measures considered | |

| Climatic data for the region collected (minimal temperatures, degress days etc) | |

| Consideration of a back up system to reduce lead time / summer hot water investigated |

3. Assess Potential Biomass Supply within the Local Area:

Why Important: Assessing the local resource is fundamental to establish whether there is the potential to establish a local supply of fuel. Limiting the distance between the end user and supplier is essential in avoiding the costs and emissions transport of fuels will incur. Furthermore establishing what type of biomass, chips/pellets/slurry/energy crops etc, is essential in determining what type of technology is required to utilise it. Opening an early dialogue with potential suppliers means that supply and demand can progress together and the supplier can be informed of your project timescales and the volume of fuel required.

Check Boxes:

| Most suitable type of fuel available identified | |

| Discussion opened with potential suppliers | |

| Outline fuel costs estimated and compared with fossil fuel alternatives | |

| Distance from fuel supply quantified | |

| Regularity of deliveries estimated (summer/winter) | |

| Size of fuel store estimated |

4. Match Demand & Fuel Supply to Available / Suitable Technologies:

Why Important: This stage is vital in ensuring the correct system is purchased to match the requirements of the organisation and the fuels available locally. For example burning gas obtained from a process such as anaerobic digestion, should there be suitable fuel available, can be compared with direct combustion and the economic and practical viability of both can be considered.

Where direct combustion is concerned the magnitude of demand will assist in identifying the most suitable type of combustion system. Below 6MW will automatically only be suited to more simple technology. Ruling out fluidised bed options which are more diverse in terms of variety of fuel they can burn. The type of system will further refine the details of fuel requirements i.e. moisture content/size chips etc Suppliers and installers will be identified at this stage. Costs can be estimated and compared with the budget.

Knowledge of the heat to electricity ratio will highlight the viability of utilising a CHP system to provide heat and electricity.

Check Boxes:

| Suitable system identified (i.e. boiler, accumulator & feed system etc) | |

| Capital / running costs outlined | |

| Maintenance requirements known | |

| Exact fuel requirements of system known and conveyed to potential supplier | |

| Exact physical size of system known and compared with space available | |

| Feasibility of CHP assessed | |

| Potential location of fuel store known and access suitability established | |

| System performance should be tested under a variety of load conditions | |

| Description of operating parameters (times, temperatures, flow rates etc) obtained |

Financial Analysis: At this juncture suitable information will be available to conduct a financial appraisal of the proposed system. This should take account of capital costs .i.e. boiler, fuel store, feed system and installation (plumbing, electrics etc) and also the running costs associated with fuel and maintenance. Fuel costs should take account of both the price of the fuel itself and transport costs.

Comparison can be made with the existing plant and also alterative fossil fuel systems of a suitable size with the difference in up front capital costs and lifetime running costs contrasted. When considering capital costs the potential for funding to offset expenditure should be factored in. It is also useful to consider forecasts of price trends for each fuel in the future. Payback periods and net present value (NPV) calculations can also be conducted. Should the results of the financial analysis be favourable progress should be made to stage five.

5. Check Relevant Legislation:

Why Important: Keeping in line with legislation relevant to utilising biomass combustion, CHP or digestion technology is essential for several reasons. Firstly it is clearly essential to comply with the law in order not to incur financial penalties or shutdown of the system for non-compliance.

Secondly the legislation in this area is aimed at sound environmental performance and therefore biomass cannot be considered a credible ‘green’ technology if it is utilised in a manner which will release air pollution emissions and create solid waste products which are not managed correctly. It is therefore prudent to consider these legal aspects early in the project to avoid difficulties and delays later on.

Check Boxes:

| Planning regulations clarified i.e. smoke free zones | |

| Regulations relating to air emissions (fly ash, particulates) reviewed | |

| Regulations relating to solid wastes (i.e. ash) understood | |

| Plan for management of waste products & legislation compliance formulated | |

| Contact made with SEPA and Local Authority to clarify situation relating to exact technology utilised |

6. Apply for Funding:

Why Important: It has already been established, during the literature review, that the capital costs of biomass systems are higher than fossil fuel equivalents. To facilitate their utilisation, which is congruent with national energy policy and climate change commitments, there are a number of funding schemes in place.

Once all the relevant information has been collected, in the previous five steps, applications can be made for the project. A successful application will make utilising biomass a more financially acceptable alternative to fossil fuels while the market is still in an immature state and therefore unable to offer lower costs due to economies of scale, in supply and technology manufacture, and the development of competition.

Check Boxes:

| Potential sources of funding identified which match project | |

| Restrictions of these funding streams identified | |

| Windows for application known | |

| Level of support available clarified (does it match budget) | |

| CO2 savings quantified | |

| Potential match funding / in kind funding investigated | |

| Financial analysis re-visited with potential funding level factored in |

7: Installation of Biomass System:

Once the preceding six steps have been undertaken it is hoped that the organisation will be able to go ahead and commission instillation. The project should have identified the best available fuel source and matched it to a system that will provide the demand required by the building in the most efficient manner. No legislation will be contravened and some capital support may be available to make the project financially viable.

Check Boxes:

| Supply contract in place for fuel | |

| Outcome of funding application known | |

| System purchased | |

| Suitable space for system to be installed | |

| Fuel store constructed | |

| Local engineers available to provide a fast response to breakdowns and defects |