An Outline of Anaerobic Digestion Technology

Introduction

Barony College already operates an anaerobic digester and reed bed as a septic system to dispose of human waste and filter water on the main campus. Anaerobic digestion (AD) technology can also be used for power production. Fuel sources of slurry and vegetable waste have been identified1; 5 and details are available in the Supply section. AD uses bacteria naturally present in waste materials. In the absence of air (hence anaerobic) or more particularly the oxygen present in air, these bacteria break down the waste to produce a significant output of methane along with traces of other gases. Such gases can then be used by means of combustion. Further purified and processed these gases can also be used in chemical (fuel cell) energy conversion, though this is outwith the scope of the project due to the high cost of such technology at present2. Other outputs of the anaerobic digestion process – liquid (known as liquor) and fibrous material – can be used directly as fertiliser or further composted3; 4.

Scales of Application

Anaerobic bio-digesters operate on an almost infinite variety of scales, from modified oil drums through community scale projects (such as are a common sight in rural China and India) up to larger automated systems4; 7. It is worth noting that smaller projects are very labour intensive for the amount of gas they produce: as a result most first world applications tend to be large and are automated as far as is practicable.

The Process

The equation for fuel production from anaerobic digestion7 is as follows:

CxHyOz + (x – y/4 – z/2)H2O

Reacts to

(x/2 – y/8 + z/4)CO2 + (x/2 + y/8 – z/4)CH4

With the general equation for energy production then:

CH4 + 2O2

Reacts to

CO2 + 2H2O + energy

Anaerobic digestion proceeds most effectively in three temperature ranges: psicrophilic (c20°C), mesophilic (c35°C), and thermophilic (c55°C). Higher temperatures lead to faster gas production, but this must be balanced against the energy input needed for heating the digester. In higher latitudes ambient temperatures are unlikely allow spontaneous psicrophilic digestion – mesophilic and thermophilic then become viable since their faster gas outputs more than balance the extra energy needed for the higher temperatures compared with psicrophilic. High water content input (including many potential waste streams) combined with a temperate climate tends to lead to an excess of energy needed for the thermophilic process, so making mesophilic most viable for a given gas output.

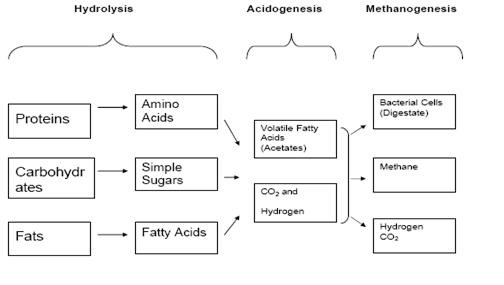

It has been established that efficient anaerobic digestion is sensitive to temperature. It is also sensitive to pH (above 7.0-7.2 inhibits methane production, below 6.2-6.4 kills bacteria necessary to the process), the proportions of nitrogen (c10%) and phosphorous (c2%), solids content, and rate of mixing. The bacterial process is outlined below3, providing that these conditions are met on a consistent basis.

The ‘golden rule’ of operating an anaerobic digester is the maintenance of constant conditions7. Monitoring is required approximately three times per hour6. It is not difficult to understand why large systems tend to be automated as far as possible.

Input Sources in the Case Study

Source |

Waste

vegetables |

Slurry |

Dry Solid Content |

15% |

8% |

Energy Value (GJ/tonne) |

1.150 |

0.625 |

Input Per Year

(tonnes) |

3500 |

9000 |

Energy Available

(GJ) |

4025 |

5625 |

Table 1: Energy Information1; 3; 5; 6; 7; 8; primarily 8

More detailed information on sources is available in the Supply section.

It should be noted that specific waste stream information – information that allows the examination of different waste types in different conditions within the context of anaerobic digestion – is difficult to come by and on occasion can differ slightly in content. This is a reflection of the comparative lack of definitive scientific work done in this area to date.

Given the latitude and climate – Scotland – and that both of the waste streams are high in water content, a mesophilic digester would be most appropriate in this case.

Available Energy and Other Outputs

Based on the information from the Renewable Energy Association the important outputs are as follows. CHP has been assumed since it has been suggested that this is the only economically viable means of using anaerobic digesters in the UK at present2; 3; 7; 8.

| Thermal output | ca 200kW |

| Electrical output | ca 110kW |

| Digestate | ca 11500tonnes/year |

The use of energy is obvious; digestate can be used directly as nutrient or further composted if required.

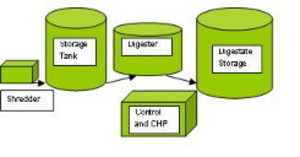

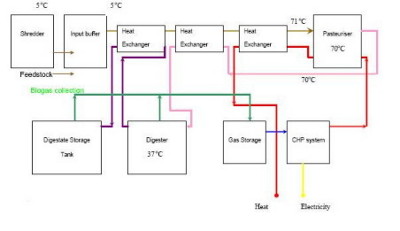

Installation

Based on the information provided by Greenfinch, foremost AD installer in the UK, the following would be required for a basic mesophilic installation: a shredder, a reception tank, a digester tank, a digestate storage tank; a control room containing heat exchangers, pumps, gas mixing and CHP unit6. The approximate area of this installation would be >0.5 hectare and graphic representations of both the physical installation and flow processes3 are shown below:

|

|

Environmental Legislation

In addition it should be noted that CHP will produce CO2, along with traces of other compounds, though this is ‘carbon neutral’ in terms of energy use. Nevertheless OFGEM (the Office of Gas and Electricity Markets) does not automatically licence bio-digester electricity production for the Renewables Obligation, reviewing on a case-by-case approach for the moment.

Economics

The following information provides the figures for the assessment.

Costs:

• Capital costs ~ £400k

• Maintenance costs @ 5% ~£25000 p.a.

• Staffing requirements two people full time6~£25000 total p.a.

• Transport costs @ £7/tonne vegetable + £3/tonne slurry ~£51500 p.a.

Income:

• Gate and transport fees @ £17/tonne x 3500 ~£59000 p.a.

• Electricity generation (assuming R.O.) @ £0.045/kWh ~ £59000 p.a.

(Generation is not guaranteed to be covered under the R.O.) and financial

value of heat at £26,000pa (from energy bills).

Recommendation: Not viable for Barony College.

References and Acknowledgements

1. Blair, Simon; Managing Director;

Solway Veg. Ltd.

2. Boyle et al.; Renewable Energy; Oxford University Press 2003; ISBN

0 19 926178 4

3. Cloonan, Maureen; Energy From Waste on the Isle of Mull: A Feasibility

Study of an Anaerobic Digestion Plant; MSc Thesis ESRU University of Strathclyde

2003; ISBN N/A

4. DTI; Summaries of the Biomass Projects carried out as part of the Department

of Trade and Industry’s New and Renewable Energy Programme: Volume

4: Anaerobic Digestion For Biogas; DTI >1997; ISBN N/A

5. Edgar, Pearl; Domestic Bursar and Facilities Manager, Barony College

6. Lucy Lewis; Research Manager; Greenfinch Ltd.

7. Twidell, J W and Weir, J; Renewable Energy Resources; F N Spon Ltd

2006; ISBN 0-419-14470-6

8. Unknown Author; Anaerobic Digestion of Farm and Food Processing Residues:

Good Practice Guidelines; Renewable Energy Association; ISBN N/A

Clarify

Standpoint of Organisation |

Quantify

Demand Requirements |

Assess

Potential Biomass Supply within Local Area |

Match

Demand & Fuel Supply to Available/Suitable Technologies |

Check

Relevant Legislation |

Apply

for Funding |