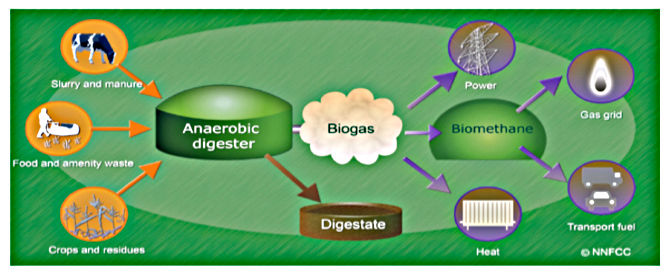

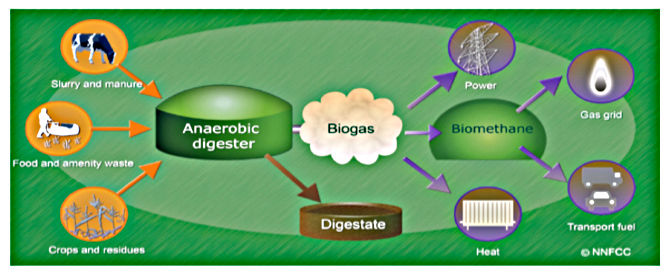

It is the process of digesting organic wastes by micro-organisms in the absence of oxygen to produce a biogas which contains mostly of methane, with also carbon dioxide and some other gases. The process takes a place in sealed tank called a digester, and when operating as a mesophilic system, runs at 25-45°C. The biogas is then converted via a Combined Heat and Power (CHP) unit to generate electricity and heat. The remaining digestate can also be utilised as a liquid bio-fertiliser that can be used for application on land (Biogas, 2019). Figure 1 below directly illustrates how the plant functions.

The main driver for choosing this technology as a long -term supply option is because of the significant availability of high organic waste in Mian Channu’s waste stream (60% approx.). Therefore, the digestion plant could be implemented to handle this significant section of the city’s waste stream, and also to produce valuable products which will benefit the supply analysis in diversifying the supply options and increasing the renewable energy penetration of the city.

The anaerobic digestion has also a positive environmental impact on improving the waste management of the city. In fact, the current city waste infrastructure is very weak and most of the waste ends up either in landfill or in streets. In addition, anaerobic digestion can boost the city economy as it is known for its labour intensity. In fact, it is estimated that a 100kW AD plant will create up to 7 jobs and indirectly sustain double this number.

Furthermore, the fundamental feature of this technology is the versatility of the output. For instance, it can produce heat, gas, electricity and bio -fertilizer, & these can be harnessed locally to reduce a community's carbon emissions (National Energy Foundation, 2019).

Consideration for the location

• It is highly recommended that the biogas plant to be located at least 5 -10 km away from the city because of its strong odour.

• Should be of minimum distance to the organic waste source, to reduce the transportation cost.

• The typical area needed for a 2.7 MW plant is approx. 12,000 m2.

The approach undertaken in order to precisely analyse the possibility of implementing this urban scale renewable technology is summarised in a number of steps as follow:

1. Technical Analysis

• Identify and predict the available organic feedstock including the quantity and the quality in the city of Mian Channu for 2030, 2040, 2050.

• Set the boundary limits of the analysis.

• Calculate the conversion of the feedstock into biogas output, on an annual basis.

• Assess how much electricity capacity can be generated from the biogas output, on an annual basis.

• Compare the electricity generation capacity against the total city energy demand.

2. Financial Analysis

Checking the viability of the plant by performing financial analysis for the three future times in a number of steps:

• Set the boundary of the analysis.

• Perform the annual cash flow for the entire lifetime of the project.

• Calculate the cost of energy produced, the net present value, and the payback period.

• Perform a sensitivity analysis on the selling price against the net present value and the payback period.