Hydrogen fuel cell electric vehicles are an emerging technology with huge potential. The technology is developing to become more scalable, which will be important if fossil fueled cars are to be prohibited to any extent due to poor air quality in city centres. Paris, Athens, Mexico City and Madrid are examples of cities who have already completely banned diesel cars. [1] With more significant traffic and congestion problems, as well as increased levels of pollution causing health problems, it is important that these cities' ethics are replicated in the encouragement to shift towards cleaner vehicles:

“The transition to zero emission road transport is both inevitable and desirable as it will improve air quality in many of our towns and cities. Hydrogen fuel cell electric vehicles can play a vital role alongside battery electric vehicles to help us cut harmful emissions.” [2]

Additionally, with pledges such as the Paris agreement, there is a need to reduce carbon emissions in prevention of global warming and climate change. As hydrogen vehicles have zero emissions, they could therefore have a huge role in helping to reach these targets.

In March 2017, it was announced that the UK government will boost the development of the hydrogen transport industry with £23 million. [2] This exemplifies the shift towards a greener future, with hydrogen vehicles playing a role in making this green future a reality.

“The transition to zero emission road transport is both inevitable and desirable as it will improve air quality in many of our towns and cities. Hydrogen fuel cell electric vehicles can play a vital role alongside battery electric vehicles to help us cut harmful emissions.” [2]

Additionally, with pledges such as the Paris agreement, there is a need to reduce carbon emissions in prevention of global warming and climate change. As hydrogen vehicles have zero emissions, they could therefore have a huge role in helping to reach these targets.

In March 2017, it was announced that the UK government will boost the development of the hydrogen transport industry with £23 million. [2] This exemplifies the shift towards a greener future, with hydrogen vehicles playing a role in making this green future a reality.

background

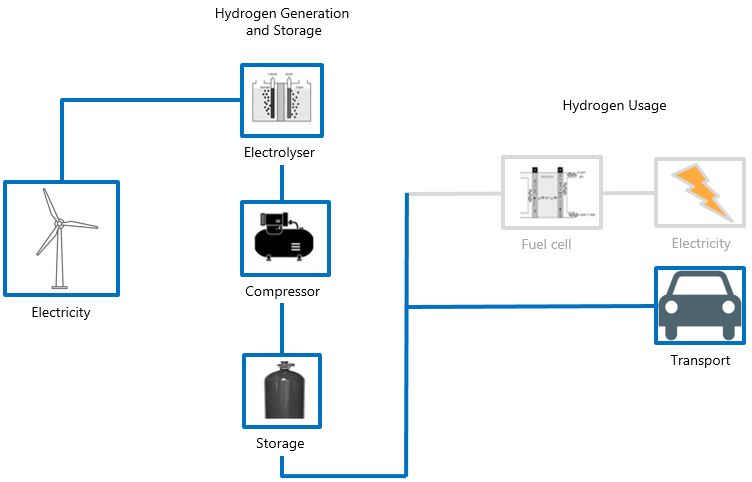

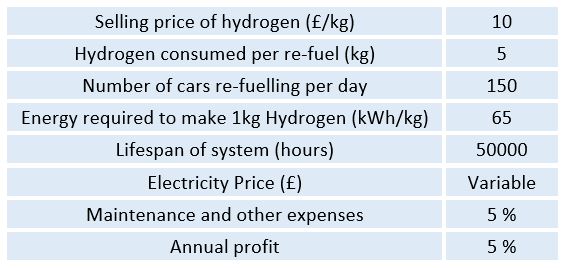

The hydrogen storage system model was applied to the second application (Hydrogen for Transport) to conduct a feasibility study of a hydrogen refuelling station (Figure 1). A mathematical model was created to study this specific application of meeting hydrogen transport demand. The model was then manipulated, by changing key variables such as the electricity prices and number of cars refuelling to replicate numerous likely future scenarios.

Commonly, hydrogen fuel cell cars require 5kg of hydrogen to refill an entire fuel tank, which includes the Toyota Mirai (Figure 2), one of the most widely used hydrogen fuel cell vehicles on the market. This amount of hydrogen allows a typical hydrogen car to drive up to 300 miles. [3] For an understanding of how hydrogen fuel compares to everyday petrol, 5 kg of hydrogen is an equivalent to 50 litres of standard petrol, and the cost is also comparable.

Hydrogen refuelling stations are being installed across the world, with some being implemented in the UK as well. Their capacity ranges from as low as 25 cars per day up to 150. The world’s largest hydrogen refuelling station operates in Hamburg (Figure 3) with a capacity of 750 kg per day, which corresponds to 150 cars per day. [5] Our refuelling station is based on the Hamburg refuelling station, designed to contain two pumps which will serve 75 cars each per day. It was assumed that each car would fill their tanks from empty to full, thus each consuming 5 kg of hydrogen per refuel.

Hydrogen refuelling stations are being installed across the world, with some being implemented in the UK as well. Their capacity ranges from as low as 25 cars per day up to 150. The world’s largest hydrogen refuelling station operates in Hamburg (Figure 3) with a capacity of 750 kg per day, which corresponds to 150 cars per day. [5] Our refuelling station is based on the Hamburg refuelling station, designed to contain two pumps which will serve 75 cars each per day. It was assumed that each car would fill their tanks from empty to full, thus each consuming 5 kg of hydrogen per refuel.

Current hydrogen prices vary between £10 and £15 per kg, which will most likely change in the future as the technology for generating hydrogen develops and becomes more common. [7] Even though the price slightly varies for different locations, the current hydrogen price at the M25 hydrogen refuelling station in Cobham, London charges £10 per kilogram.

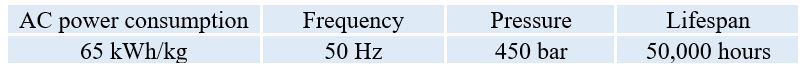

In our system, hydrogen is produced through the electrolysis of water and so electricity from the grid is required. A mathematical model was constructed using the technical parameters of the system manufactured by HYDROGENICS – Advanced Hydrogen Solutions. [5] The chosen HySTAT system consumes 65 kWh/kg of hydrogen, and this includes the AC power consumption not only of the electrolyser but also of the accompanying compressor. The system is designed to operate at a frequency of 50 Hz, which aligns well with the European market. Hydrogen is stored in hydrogen tanks at 450 bar, which is standard practice. Hydrogen tanks are offered as a part of the system, and should be placed near the refuelling station. HYDROGENICS produces systems with four stacks in the electrolyser, which generate up to 130 kg of hydrogen per day. For this reason, our system had to contain an appropriate number of stacks to meet the transportation demand.

Methodology

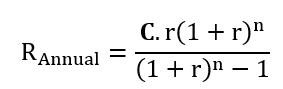

Various assumptions have been introduced when creating the mathematical model which will be further discussed later in this section. The mathematical model was created in MicroSoft Excel to obtain key results for each scenario. The main purpose of the mathematical model is to calculate the annual profit of the system. This has been estimated at 5% of the gross profit per year. Another 5% was dedicated to maintenance and other expenses, while the rest was used to repay the loan of the system. As the capital of the system was very difficult to estimate, due to the current immaturity and complexity of the infrastructure, another approach was applied: the model uses the capital loan equation and works backwards from there (as shown in Equation 1). This approach provides the money available to build the system. Therefore, if the system capital cost is equal or below this value it is economically feasible to go ahead with the project. This gives the model important future flexibility, as it is not dependent on various capital costs of each part which changes significantly over the time.

To calculate the amount of money available to build the system, Equation 1 was used. The known variables of our system are: net profit per year, interest rate and the repayment period.

To calculate the amount of money available to build the system, Equation 1 was used. The known variables of our system are: net profit per year, interest rate and the repayment period.

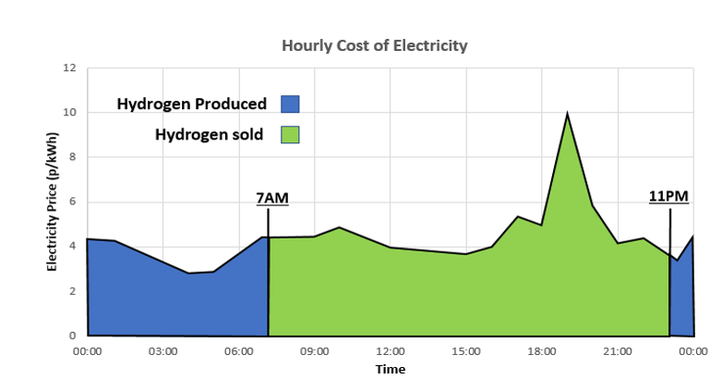

The initial model was based on electricity prices that correspond to a typical day in March 2017. The exact values were gained from a source that collects hourly electricity prices in the UK and overseas (Figure 4). Even though this parameter is fixed for most of the models, this can be easily changed in our model allowing flexibility for the model to be used in the future. All Excel sheets are linked to each other, and so the model can be used any time in the future by inserting updated hourly electricity prices in the adequate row. This will automatically change all result tables and graphs that can be used. The price to generate hydrogen corresponds to the real price at the given hour, and the cost per day is then summed automatically. This value must be subtracted from the gross daily profit made by selling the stored hydrogen.

The model was designed in a way that it takes electricity from the grid when it is at its cheapest rate. The power is then used to electrolyse water to create hydrogen, and is compressed to 450 bar afterwards. As Hydrogenics provides technical parameters for both stages together, the mathematical model includes only one value for the electricity consumption. This value is stated as 65 kWh/kg of hydrogen. [5]

A high pressure storage tank is a part of the Hydrogenics system, and its size must be equal to the daily hydrogen demand. The losses in the hydrogen tanks are less than 1% and considered negligible [5], thus were not factored into our model. These assumptions were also consulted and approved by members of the Bright Green Hydrogen office in Methil.

To ensure the reliability of our hydrogen refuelling station, the station was designed to be closed between 11pm and 7am, so the system can be refuelled when the electricity is cheapest (Figure 4). This prevents the system from being unable to meet the hydrogen fuel demand which could result in losing potential customers.

The model was designed in a way that it takes electricity from the grid when it is at its cheapest rate. The power is then used to electrolyse water to create hydrogen, and is compressed to 450 bar afterwards. As Hydrogenics provides technical parameters for both stages together, the mathematical model includes only one value for the electricity consumption. This value is stated as 65 kWh/kg of hydrogen. [5]

A high pressure storage tank is a part of the Hydrogenics system, and its size must be equal to the daily hydrogen demand. The losses in the hydrogen tanks are less than 1% and considered negligible [5], thus were not factored into our model. These assumptions were also consulted and approved by members of the Bright Green Hydrogen office in Methil.

To ensure the reliability of our hydrogen refuelling station, the station was designed to be closed between 11pm and 7am, so the system can be refuelled when the electricity is cheapest (Figure 4). This prevents the system from being unable to meet the hydrogen fuel demand which could result in losing potential customers.

The initial model is based on the capacity of refuelling 150 cars per day which is the current capacity of the hydrogen refuelling station in Hamburg. The system electrolyses water to create hydrogen for 8 hours every day, and the ideal time allocated to hydrogen generation is discussed in the following section. Each car is expected to refuel its tank from empty to full, which requires 750 kg of hydrogen per day.

The price of hydrogen was set to £10 per kg of hydrogen in most scenarios, however the different prices have also been considered. This may be achieved by government incentives for clean transport. This variability is further studied in one of the scenarios that were backed up by the mathematical model.

RESULTS aND Discussion

A sensitivity analysis was conducted in order to identify which variables affected the profitability of a site. A "current" scenario was evaluated before altering variables such as the input electricity price, quantity of cars using the station, and the selling price of hydrogen. These variables were changed individually and then together. This was useful in identifying which key parameters were important when considering making the system feasible from an economical perspective.

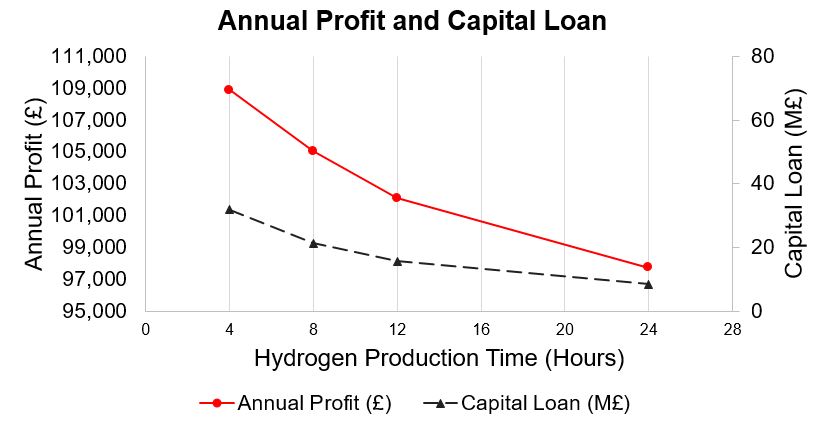

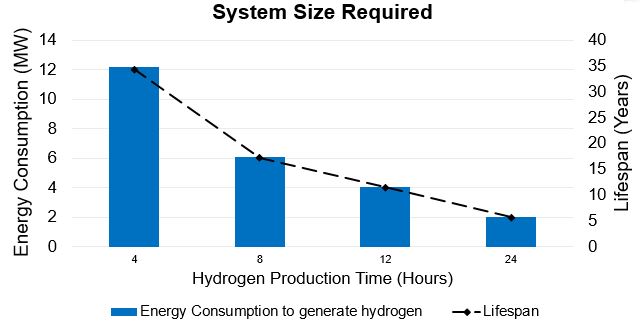

Within the modelling of the variables, the time allocated for hydrogen generation was explored using current electricity prices. It was found that this parameter had a significant impact on the profit, as shown in Figure 5. When the amount of time taken to generate hydrogen was increased, the profit decreased. This was primarily due to the fluctuation of electricity prices. On the other hand, some of the advantages of a 24-hour site included having smaller storage requirements and therefore the infrastructure required would be cheaper and also includes the compressor and electrolyser. While the infrastructure would be cheaper and smaller, thus reducing the land requirements, the lifespan in years dramatically decreases for a 24-hour system, as shown in Figure 6. This means that the system would have to be replaced more frequently, which would therefore affect the profitability of the system.

When a 4-hour system was investigated, it was found to be very profitable (compared to larger allocated times) as shown in Figure 6. This was mostly due to the fact that electricity prices were significantly lower – sometimes reaching towards being zero. The 4-hour system is based on the principal that hydrogen generation is conducted when the electricity price is at its lowest in order to maximise profits. While being profitable, the lifespan in years is also much higher, which is desirable. Some drawbacks of a 4-hour system however include that if all of the demand of hydrogen is required to be stored in preparation for a working day, a significant size of storage is required. This is expensive and requires a lot of space, which may be problematic for a site due to limitations of land availability and technological demand.

A system with 8 hours of hydrogen generation was selected. This was concluded to be the most suitable system with a compromise in infrastructure price (as the capacity of the system is lower than the 4-hour system), the lifespan is higher than 12 or 24-hour systems and most importantly the high annual profit is still retained. When considering all of these parameters, it was decided that the 8-hour system was the most beneficial.

Within the modelling of the variables, the time allocated for hydrogen generation was explored using current electricity prices. It was found that this parameter had a significant impact on the profit, as shown in Figure 5. When the amount of time taken to generate hydrogen was increased, the profit decreased. This was primarily due to the fluctuation of electricity prices. On the other hand, some of the advantages of a 24-hour site included having smaller storage requirements and therefore the infrastructure required would be cheaper and also includes the compressor and electrolyser. While the infrastructure would be cheaper and smaller, thus reducing the land requirements, the lifespan in years dramatically decreases for a 24-hour system, as shown in Figure 6. This means that the system would have to be replaced more frequently, which would therefore affect the profitability of the system.

When a 4-hour system was investigated, it was found to be very profitable (compared to larger allocated times) as shown in Figure 6. This was mostly due to the fact that electricity prices were significantly lower – sometimes reaching towards being zero. The 4-hour system is based on the principal that hydrogen generation is conducted when the electricity price is at its lowest in order to maximise profits. While being profitable, the lifespan in years is also much higher, which is desirable. Some drawbacks of a 4-hour system however include that if all of the demand of hydrogen is required to be stored in preparation for a working day, a significant size of storage is required. This is expensive and requires a lot of space, which may be problematic for a site due to limitations of land availability and technological demand.

A system with 8 hours of hydrogen generation was selected. This was concluded to be the most suitable system with a compromise in infrastructure price (as the capacity of the system is lower than the 4-hour system), the lifespan is higher than 12 or 24-hour systems and most importantly the high annual profit is still retained. When considering all of these parameters, it was decided that the 8-hour system was the most beneficial.

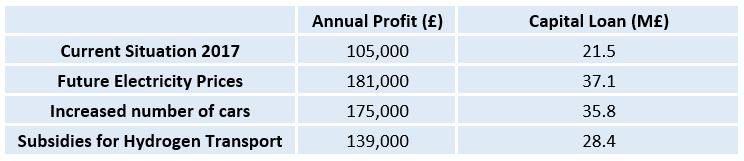

For a system closed for 8 hours for hydrogen production, it was found that when the input electricity price was decreased, the profit increased. The new electricity prices are based on a network that has more renewables online, compared to today, and therefore would have a larger excess of generation at times allowing for cheaper, free or even negative electricity prices. Electricity can be bought at peak generation times to prevent renewable energy systems from being curtailed, thus maximizing the potential of the technology’s energy output while also making more profit.

In a scenario with higher demand, an increase in the number of customers refuelling hydrogen fuel cell electric vehicles, the profits were found to increase due to an growth in number of sales. The 8-hour closure system was used with current electricity prices and the number of vehicles increased to 250 cars visiting each day. This is the average number of cars visiting a petrol station daily in the UK. [10] All other variables remained the same.

The last scenario considered the implementation of government incentives, and how they would enhance the financial feasibility of the hydrogen refuelling station. The UK government is committed to decarbonise transport sector and therefore have recently announced funding to support hydrogen vehicles, infrastructure and implementation of hydrogen refuelling stations UK wide. Our model assumed that government subsidies will pay £2.5 for every kilogram of hydrogen sold to customers, thus the refuelling station received £12.5 per kilogram of hydrogen. It was assumed that the real price customers have to pay remained £10 per kilogram, and 150 vehicles were refilled every day.

The annual profit and capital value required for loan, of each scenario described, are displayed in Table 3. Each scenario revealed parameters that affect the profitability of the system. An ideal scenario would combine the advantages of each scenario, in this case utilising future electricity prices as well as having an increased demand. The associated Excel sheets can be downloaded from the links below, and the input variables can be adjusted to suit any system.

The last scenario considered the implementation of government incentives, and how they would enhance the financial feasibility of the hydrogen refuelling station. The UK government is committed to decarbonise transport sector and therefore have recently announced funding to support hydrogen vehicles, infrastructure and implementation of hydrogen refuelling stations UK wide. Our model assumed that government subsidies will pay £2.5 for every kilogram of hydrogen sold to customers, thus the refuelling station received £12.5 per kilogram of hydrogen. It was assumed that the real price customers have to pay remained £10 per kilogram, and 150 vehicles were refilled every day.

The annual profit and capital value required for loan, of each scenario described, are displayed in Table 3. Each scenario revealed parameters that affect the profitability of the system. An ideal scenario would combine the advantages of each scenario, in this case utilising future electricity prices as well as having an increased demand. The associated Excel sheets can be downloaded from the links below, and the input variables can be adjusted to suit any system.

| Excel Sheets Increase of Demand; Incentives for Hydrogen Transport.xlsx | |

| File Size: | 77 kb |

| File Type: | xlsx |

| Excel Sheets: Original Pricing; Future Electricity Prices | |

| File Size: | 147 kb |

| File Type: | xlsx |

[1] https://www.theguardian.com/environment/2016/dec/02/four-of-worlds-biggest-cities-to-ban-diesel-cars-from-their-centres

[2] https://www.gov.uk/government/news/23-million-boost-for-hydrogen-powered-vehicles-and-infrastructure

[3] http://www.nextgreencar.com/fuelcellcars/

[4] http://www.caranddriver.com/toyota/mirai]

[5] HYDROGENICS Advanced Hydrogen Solutions, Hystat Hydrogen Fueling Stations

[6] Power-Hydrogenics Overview - Power Systems 2012-02.

[7] http://www.shell.com

[8] http://www.esru.strath.ac.uk/Courseware/Class-ME909-ME922-ME927/Assignments/wind_assignment.pdf

[9] http://www.nordpoolspot.com/Market-data1/N2EX/Auction-prices/UK/Hourly/?view=chart

[10] UK fuel market review. Fuel retail. RAC Foundation. Deloitte, 2013.