- General Considerations

- Specific Considerations

Mabie Farm Park - Biomass

According to the methodology, the analysis is divided into 2 parts: Anaerobic Digestion and Biomass Boiler.

Biomass BoilerAs mentioned in the methodology, there are three supply chain options for wood fuel: self-supply, contract locally or supply from an energy service company. For Mabie Farm Park, there is no wood fuel source available on site - even though it is surrounded by Mabie forest - because the purpose of the farm is for recreation and there is no forestry area belonging to Mabie farm.

Contracting locally seems to be the best option because, as mentioned earlier, Mabie farm is surrounded by forestry area which belongs to the forestry commission.

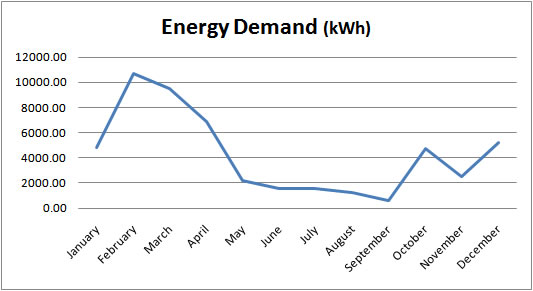

A biomass boiler is suitable for supplying space heating and hot water heating. The space and water heating demand for Mabie farm is shown in the table below. Graph 1 also shows the total energy demand for space heating and hot water heating in each month.

Table 1. Space and Hot Water Heating Demand

January 3852 910 43 4805 February 9157 1441 102 10700 March 8025 1289 182 9495 April 5781 790 326 6897 May 1573 0 653 2227 June 0 0 1539 1539 July 0 0 1580 1580 August 0 0 1266 1266 September 0 0 624 624 October 3951 645 182 4778 November 1983 499 42 2524 December 4170 991 43 5204 sum 38493 6565 6582 51639

Graph 1. Total Energy Demand for Space and Hot Water Heating

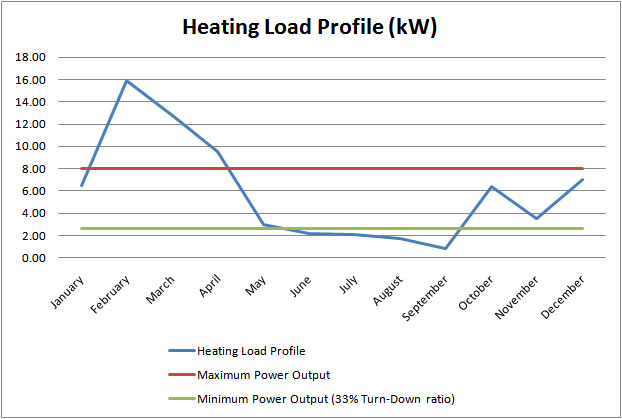

According to our methodology, after we define the energy demand we can then size the biomass boiler, calculate the amount of biomass energy supply and make an economic analysis. Graph 2 shows the boiler sizing analysis for which the conclusion is shown in table 2.

Graph 2. Boiling Sizing

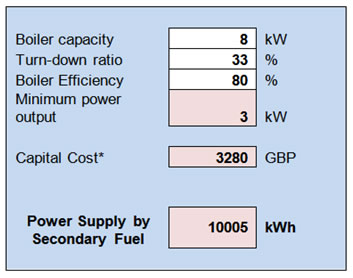

Table 2. Woodchip Boiler Condition

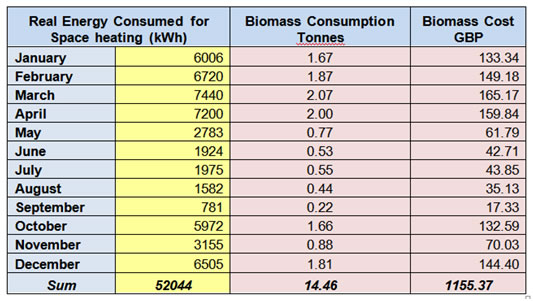

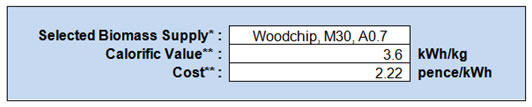

Table 4 shows the fuel cost calculation. In this case study we used woodchip with 30% moisture content as the fuel supply (characteristics are shown in table 3).

Table 3. Woodchip Characteristics

Table 4. Fuel Cost Calculation

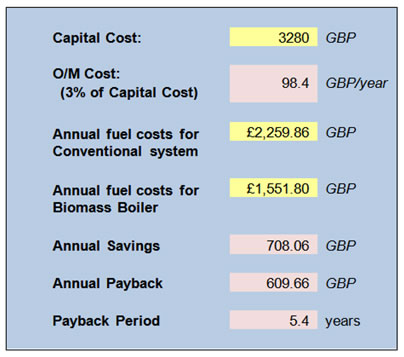

The outcome of the analysis shows that we can use the biomass boiler to supply 80% of all the heating demand. The boiler capacity required is 8 kW with a 1:3 turn down ratio which has a capital cost of around £3,280 (with the assumed operation and maintenance costs as 3% of capital cost). This biomass boiler will be installed to replace 80% of the energy supply by the conventional fuel system which in this case study is a kerosene boiler. Therefore, we can make an economic analysis and calculate the payback time for which the results are shown in table 5 below.

Table 5. Cost Analysis

The full calculation spreadsheet can be download here

| MSc: Renewable Energy Systems and the Environment | © University of Strathclyde 2010 |