- General Considerations

- Specific Considerations

Mabie Farm Park - Heat Pump

Mabie Farm Park is a small commercial establishment and all the buildings are well insulated. Since there is a large variation in the atmospheric temperatures and availability of land area, it was decided that ground source heat pumps were most suitable for this location.

Ground temperatures (source temperature):

Calculating the ground temperatures is very important in designing a ground source heat pump for heating. It is the source temperature for the heat pump and the performance of the heat pump depends upon this.

The temperature distribution at different depths over the course of a year can be calculated using a correlation developed by KASUDA. T:

Graph 1. Ground temperature profile at different depths over a year of time

From the graph, it was found that at a depth of 2 m the temperature varies less over the year; with an average temperature of 8.4°C chosen as the source temperature. Details of the atmospheric temperatures were taken from RET Screen software.

Detailed calculations in an excel spreadsheet can be download here

Distribution temperature:

Presently, the building is heated through low temperature radiators which need a distribution temperature of 50°C to maintain normal temperature. Generally, heat pumps are more effective with an under floor heating system, but in this case changing the heating system to under floor heating for such a large floor area requires huge capital costs and lengthens the payback period.

Coefficient of performance (COP) of heat pump:

From the source temperature of 8.4°C the compressor has to raise the temperature up to 50°C. Since there is demand for hot water, this has to be raised up to 55°C. For this temperature lift the heating coefficient of performance (COP) is 3.48, according to Canadian Standards.Sizing of heat pump:

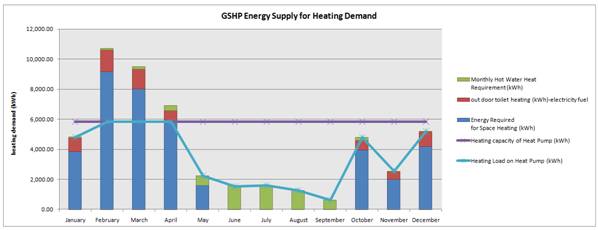

If we observe the heating demand in Figure 1 there are some peak loads. Since the capital cost of a heat pump system is very high compared to other systems, it not a good idea to design the heat pump for peak loads. Therefore, in this case the heat pump is designed for 8 kW (based on payback period and carbon emissions). The load above this is provided by an existing conventional boiler.

Figure 1. Heat Pump Sizing

Cost analysis:

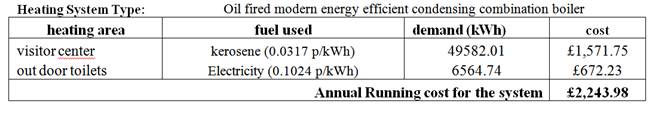

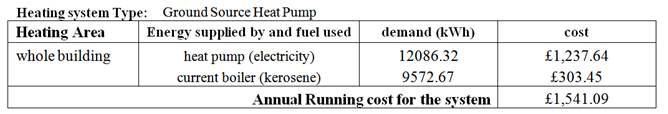

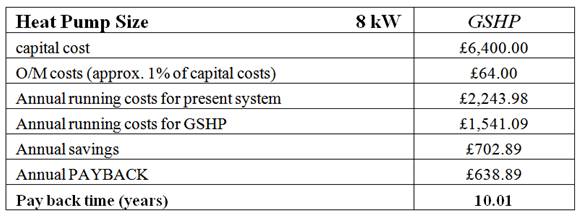

The capital costs for heat pumps were taken from the Energy Savings Trust and the operation and maintenance costs were assumed as one percent of the capital cost per annum. The running costs for the current system and proposed heat pump system were calculated:

Table 1. Running costs for the current system

Table 2. Running costs for the proposed system

By comparing the running costs of both systems, the annual saving is £703. The payback period is as follows:

Table 3. Cost analysis of the Proposed System

The spreadsheet and detailed calculations for the GSHP system can be found here.

The proposed heat pump system has a payback period of 10 years.

| MSc: Renewable Energy Systems and the Environment | © University of Strathclyde 2010 |