Fuel Calculator Manual

One of the first steps in the process of defining a biomass heating system is to know the characteristics of fuel that will be used. It is important, because together with boiler efficiency and energy demand, it will define the rate at which the wood will be consumed, the size and kind of storage system and the price per unit of energy generated.

The Inputs

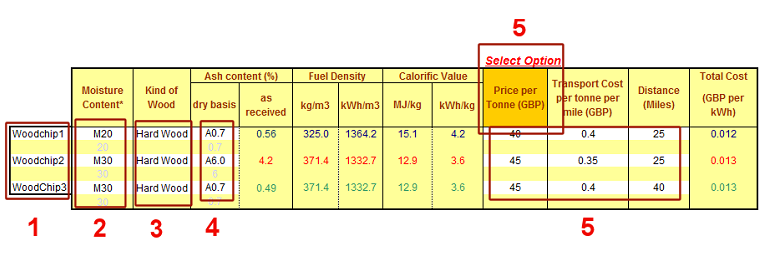

The inputs are always inside the white cells. The picture below is a screenshot of the main table:

1 – Fuel Supplier: This input area may be used in case the user wants to identify the fuel by its supplier or by any other name that he may find useful. All other parts of the tool will update automatically and display the new name.

2 – Moisture Content: Following the CEN/TS 14961:2005, this field will identify the moisture content of the fuel. A drop down menu shows the possible options. These values are independent for each supplier and can be changed at any time.

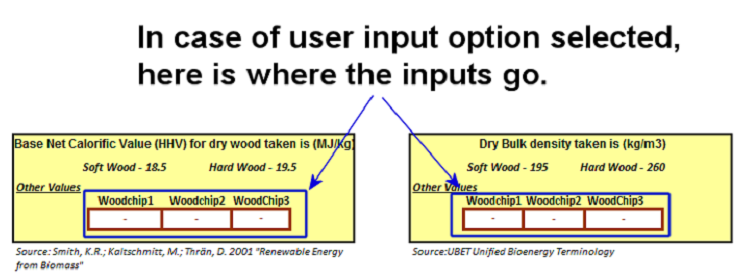

3 – Kind of Wood: Three options may be selected here – Hard wood, soft wood and user input. Depending on this input, the values utilized for calorific value and density are automatically defined. The option user input allows the user to avoid the preset values and input his/her own data.

The calorific value and bulk density utilized for each dry kind of wood is shown below:

Kind of Wood |

Density (kg/m3) |

Calorific Value (MJ/kg) |

Soft Wood |

195 [*] |

18.5 [**] |

Hard Wood |

260 [*] |

19.5 [**] |

[*] Reference: Food and agricultural organization of the United Nations, (2004). UBET Unified Bio-energy Terminology

[**] Reference: Smith, K.R.; Kaltschmitt, M.; Thrän, D. 2001 "Renewable Energy from Biomass"

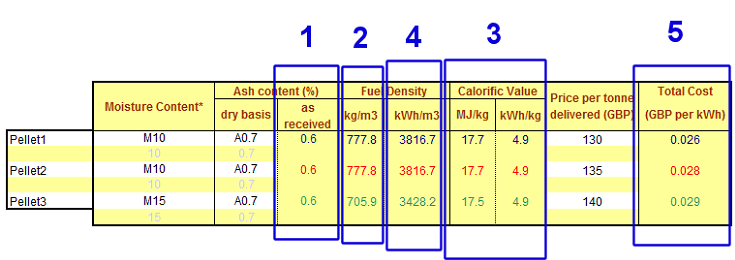

In the wood pellet part, there are no pre-set values. This is because each wood pellet producer may compress the wood in a different way, therefore there isn’t a default value for calorific value or bulk density. In this case, the input of the data is done just like if the “user input” option is selected in the wood chip table.

4 – Ash Content: The options shown in this menu also follow the CEN/TS 14961:2005 specification. Its function is similar to the one of the moisture content.

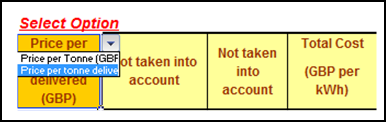

5 – Fuel Price: Each supplier of wood, just like with any fuel, will ask a different price for his product. Depending of supplier, the price of wood may be depend not only on amount ordered, but also distance of delivery or only on the amount ordered regardless of distance. In this case the transport and delivery cost is already included. Because of these differences, the user has an option to, in the first column of this spreadsheet, select if the prices will be calculated as “Price per tonne delivered” or “Price per tonne”. If the second option is seletcted, it is necessary to input the transport cost in GBP per tonne of fuel and the total distance in miles.

Once more there is a difference in this part between the woodchips and the wood pellets. Wood pellets are usually priced just like more usual fuels, price per amount of fuel delivered. In case of wood pellets, there isn’t an option to set the price of the delivery and weight independently.

The Outputs

The outputs of this part may be used by the user to compare some features of each provided fuel but also will be combined in other elements of the tool, helping to decide how feasible a biomass system may be. These outputs are shown below:

1 – Ash content “as received” [%]: This information associates the dry basis ash content with moisture content of fuel to define ash content in the delivered fuel. For that, the following formula was applied:

2 – Fuel Density [kg/m3]: The density of the delivered fuel will take into account its value input for dry fuel and then take into account moisture content specified by the user. This is calculated in kg/m3:

3 – Calorific Value [kWh/kg]: The calorific value of the delivered fuel takes into account the amount of water present in it and the base value specified, as shown below:

Where:

- CVr represents the Calorific Value as received

- CVd represents the Calorific Value of dry mater

- MC represent the moisture content of fuel

- 0.2443 is the correction factor of enthalpy of vaporization (constant pressure) for water (moisture) at 25 °C. [MJ/kg per 1% of moisture][*]

This calculation shows the result in MJ/kg. Since this output will be utilized to define the total cost of kWh (energy) purchased, this value is converted to kWh/kg by dividing it by 3.6.

[*] Reference: Alakangas,E. Wood Fuel Properties and standardisation.

4 – Fuel Energetic Density [kWh/m3]:

Later on, in order to calculate the storage system size, it is necessary to know the amount of volume that a given quantity of energy will require. Using the other results it is possible to calculate this “energetic density”:

5 – Energy Cost [GBP/kWh]:

A very important output at this stage is how much will the energy provided by each supplier cost. That is done by combining previous inputs and outputs. One of the used inputs is the price per tonne of the fuel (delivered or not). Since the user may work in two different ways with these inputs, the calculation of the energy cost is done differently depending in the user selection.

In case the user decides to input the price of the fuel delivered, where distance from supplier and transportation cost are already taken into account (or irrelevant) the following formula was applied:

The second option - when the delivery cost and the fuel cost are separate. In this case, the following calculation was used:

Once those inputs and outputs are given, the user may go to the next step, boiler sizing to keep progressing with the feasibility study. At any time though, he may return to this step and change any value.