Woody Biomass

Practically any material made of wood can be classified as woody biomass. This may also include bushes and shrubs. They will be differentiated between themselves based on how they were extracted and processed. The origin can vary from forest residues - woodland thinning, arboricultural trimmings – untreated wood waste, like the ones from saw mills or furniture factories, residues from farming activities like straw, or even from energy cropping, of which willow plantation is a good example.

Wood can be exploited for generation of energy in different forms. Three types of wood can be taken as most popular in heat generation: Logs, woodchips and wood pellets.

Before analysing these three forms, it is important to add some information about quality of wood fuel. One of the most important information is the moisture content of the fuel, whose importance is directly related to fuel calorific value. Emissions and contamination levels are also important issues which must be addressed and clarified when deciding what kind of fuel to utilize and when dealing with the supplier.

Calorific Value – Moisture Content

The mass that needs to be burned in order to produce a given amount of energy is one of the main characteristics of any fuel. Of course for wood it isn't different. The calorific value indicates the energy released as heat when a compound undergoes complete combustion with oxygen. Usually given in kJ per kilogram or kJ per kWh, each kind of wood will show a different calorific value. This variation is actually small between similar trees. That is why, usually, when referring to calorific value of wood fuel, it is informed whether it originated from hard or soft wood. A sensitivity test performed using our biomass feasibility tool observed that a mistake in the precision of the calorific value of a given wood fuel in the order of 5% would be hardly noticed by the system (observed in a 300~500 kW system with a storage capacity of 46 m3 located in East Scotland) . It will neither affect the final cost of fuel per kWh generated nor will be noticed with the amount of days the storage system will last.

It is not hard to understand how the moisture content affects the calorific value of a given fuel. When dealing with wet fuel, extra energy will be spend on heating and evaporating the water present before combustion can take place. Following the CEN/TS specifications (14961:2005), the moisture content is usually divided into categories for which a given percentage of water inside a wood fuel sample may be accepted.

An example of these categories can be seen below, for woodchips and wood pellets.

Wood Chips

M20 |

Moisture ≤ 20% |

Dried |

M30 |

Moisture ≤ 30% |

Suitable for Storage |

M40 |

Moisture ≤ 40% |

Limited For storage |

M55 |

Moisture ≤ 55% |

|

M65 |

Moisture ≤ 65% |

Wood Pellets

-

M10

Moisture ≤ 10%

M15

Moisture ≤ 15%

M20

Moisture ≤ 20%

In the wood chip table, the third column is important. It refers to another important issue that might be brought by high concentration of water into a given woody fuel: decomposition and mould formation. Good ventilation of the storage area may help to neutralise this problem. In other cases, a drying process before storing may be necessary.

For one kind of wood (in order to maintain the dry calorific value constant) and using the biomass feasibility tool it is easy to visualize the influence of moisture content on a given wood fuel (as shown below).

The higher the moisture content, less energy per kilogram is released during combustion. As a result, the energy generatioin cost is higher and the storage system has to be larger.

Ash Content - contamination

The non combustible content of woody biomass is referred to as ash. It can be a part of the wood source, e.g. deposited within the biomass during plant growth or contaminant such as dirt, sand or even heavy metals. It is usually expressed as a dry basis or in other words the percentage of mass that won’t be a part of the combustion process, assuming a moisture content of 0%.

The main problems with ash content are not directly related with the energy production but with emissions and maintenance.

Problems may occur when, for example, highly contaminated ash melts forming lungs of slag, which may block grates and cause erosion or jamming of ash augers. More ash means more maintenance for cleaning, which may rise the cost of keeping the system running.

Another issue may result from the emissions present with highly contaminated ash. The higher production of NOx, PM10, and heavy metal may cause environmental problems.

Its presence in the fuel is indicated in a similar way to how it is done with moisture content. CEN/TS 14961:2005 also provides specification about how those contents may be categorised, as shown below:

Ash content wood chip

Ash Content (dry basis) |

|

A0.7 |

Ash content ≤ 0.7% |

A1.5 |

Ash content ≤ 1.5% |

A3.0 |

Ash content ≤ 3.0% |

A6.0 |

Ash content ≤ 6.0% |

A10.0 |

Ash content ≤ 10.0% |

Ash content wood pellet

Ash Content (dry basis) |

|

A0.7 |

Ash content ≤ 0.7% |

A1.5 |

Ash content ≤ 1.5% |

A3.0 |

Ash content ≤ 3.0% |

A6.0 |

Ash content ≤ 6.0% |

A6.0+ |

Ash content ≥6.0% |

Forms of wood fuel

Having a better understanding of what the main characteristics of a wood fuels are, the forms at which they usually are utilized may be introduced. Wood logs, wood chips, pellets, straw and even liquid fuels produced from wood and bales of compressed forest residues are examples of it. The feasibility tool was designed to work with wood pellets and wood chips, usually the kinds of fuel utilized with systems from 50 kW upto approximately 1 MW. These two types of fuel are described bellow:

Wood Chips

Whole trees, branchwood and coppice products may be mechanically shredded by a chipping machine in order to create wood chips. These wood sources may come from forest thinning, arboricultural trimming, energy cropping or even residues from activities such as furniture creation.

Given the variety of sources from which the chips may be created, the range of moisture content (from now on referred as MC) may be wide. A dry wood would be around the 20% of MC, with a reasonable value around the 30% and in case of green wood, recently extracted and chipped, being able to reach 60% of MC, what in most cases would request drying before being used in a biomass boiler or even stored.

Another important factor, especially when sizing a biomass system, is defining the density of utilized fuel. Knowing this value, adding information about moisture content and calorific value, one may determine total energy available per kilogram of wood. Just like with calorific value, knowing the kind of wood utilized (soft or hard) the dry bulk density (when wood is considered completely dry) may be defined: 195 kg/m3 for softwood and 260 kg/m3 for hardwood [2].

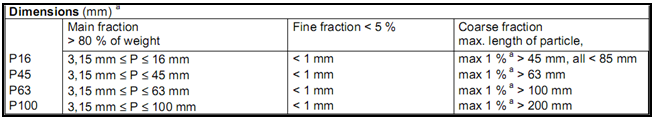

One last important attribute involves dimensions of a chip. Different boilers may have different maximum size of chips which they are be able to burn. Once again working with ranges, the following were defined by the CET/TS 14961:

Wood Pellets

Saw dust or wood shavings may be compressed in order to create what is known as wood pellets. This compression process allows wood pellets, in an overall view, to be a more concentrated form of fuel. In this way, smaller storage site needs to be built or refill can be less frequent. On the other hand, it requires more energy to be created, thus rising its price (which is usually higher than of wood chip).

Compared with wood chips, wood pellets are usually drier, with moisture content rarely above 20% and produce less ash. This makes storage and maintenance of the system simpler. Being more practical to handle, usually containing less contamination and having a possibility to be stored in hoppers, pellets are a very flexible fuel, which can be used for small residential heating (around 9kW) as well as big power generation (for example Longannet, a power station in Scotland with capacity of 2.4 MW, where wood pellet are mixed with coal before the burning process).

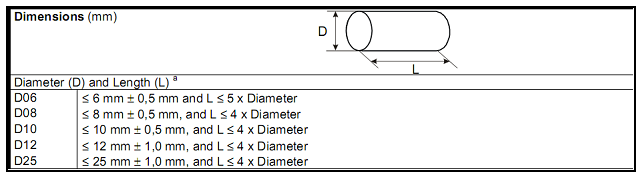

Just like with woodchip, is important to know the dimensions of the pellet and compare with the capacity of the boiler installed. CET/TS gives the following specification:

Since each wood pellet producer may use a different kind of wood and compress a wood pellet in a different way, there is neither a standard calorific value nor fuel density. This information must be provided by the supplier.

[2] Food and agricultural organization of the United Nations, (2004). UBET Unified Bio-energy Terminology.