Case study - Scottish hotel

The aim of this study is to compare the results of the tool with information supplied in a report on feasibility of a biomass system for a small hotel in east Scotland. The building is an old house built in the middle of the 18th century but refurbished and expanded in the beginning of the 20th century. Its a capacity is around 200 guests and also includes two other buildings, one being an accommodation for students and the other an activity centre.

Main house boiler system sizing

The first part of the study will observe the results from the tool during the process of calculating the parameters of the biomass system, taking into account only the demand of the main house. The process will include everything from the heating demand calculation upto the storage system sizing.

Since it's an old building, the U values were changed, following the indications from SAP 2005. The new ones are shown below (in W/m K):

| Stone walls | 1.7 |

| Windows | 3.1 |

| Doors | 2.0 |

| Rooftop | 2.3 |

| Floor | 1.2 |

The building is a 2 floor house with a total floor area of 3200 m2.

0.5 air changes per hour were specified, internal temperature of 21 °C and OAT of -5 °C.

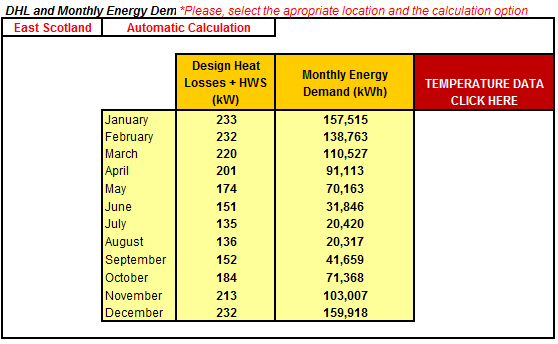

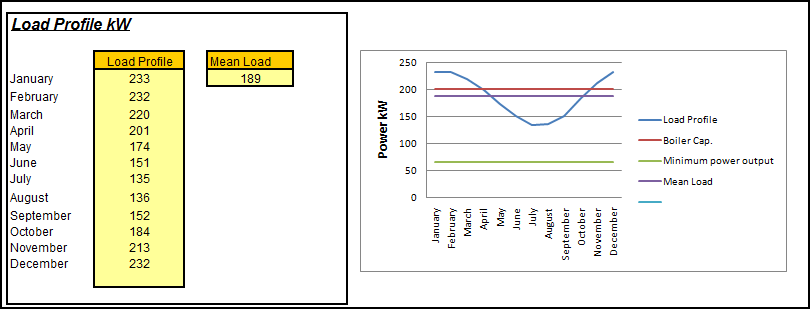

The following load profile and energy consumption were obtained:

For this load, through an automatic calculation, the tool sized the boiler - 200 kW, which is 30 kW below the mean load for the winter. The report identified this load at 255 kW, suggesting a 250 kW boiler. An auxiliary boiler, fuelled by gas or oil, was recommended by the tool in order to supplement the heat demand. It was sized at 105 kW, almost the same value as suggested by the report (100 kW).

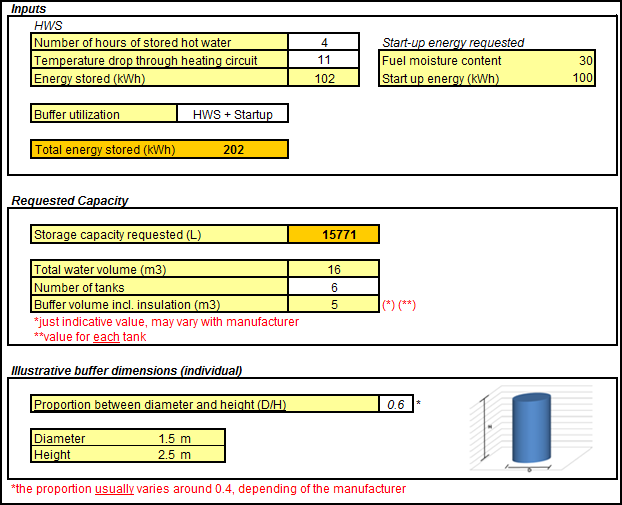

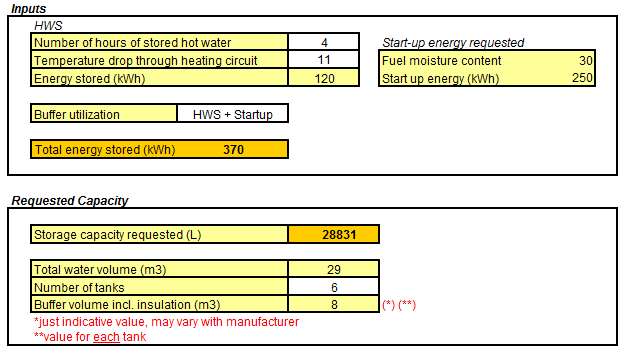

The next point where results could be compared is the thermal buffer sizing. In the report there was no clear information about which factors were taken into account. We considered the amount of energy to be stored in order to supply the mean hot water demand for 4 hours and energy for the boiler start-up (thermal lining heating). It indicated the requirement of 16 000 L of water, against 25 000 L suggested by the report. It is important to remember that the buffer sizing depends completely on how the control system is configured. For example, if the calculations were for 8 hour of mean hot water demand, the tool would size the same amount of water as the one shown at the report.

Another interesting point of comparison would be the annual cost of the fuel or the annual savings. There is no data about the energy consumption of the hotel, what makes a precise comparison impossible. Although, it is possible to overwrite annual consumption calculated by the tool, with the one provided in the report - the entire system consumption and calculate the savings.

After doing that, the tool calculated, for an annual consumption of 900 000 kWh, an annual fuel cost of 13 500 GBP, and, when taking place of an oil boiler, annual saving of 7 000 kWh - both values similar to the ones in the report.

Thermal buffer size analysis

In this case, the biomass system was implemented, but not as the feasibility report suggested - some sizes and configuration of the elements of the system were different.

During the site visit we were informed that one problem they have with the system is that during the coldest nights of the year the heating process is taking too long. We were also informed that the buffer system has a capacity of 4 000 L of water and probably is the source of the problem.

We decided to try to use the tool to study this case and check if it was able to identify where the problem could be.

Since the aim here is not calculating heat demand of the hotel (those values are already known) we will focus on the size of the boiler and the thermal buffer system. Any other input was changed to “user input” in order to avoid automatic calculations.

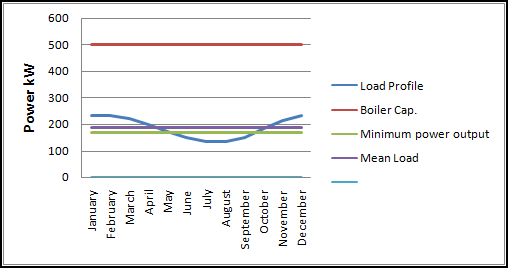

For a winter mean load of 490 kW, the tool sized a boiler with 30% turn-down ratio and capacity of 400 kW. The same value is suggested in the report. The building has a 500 kW boiler actually installed. This is more than enough to supply the base load. Using the installed size of the boiler instead of the one calculated, it is observed that the minimum power output is 167 kW. There is no information about the total load profile for this installation, but the study of the main house load indicated a summer mean demand of 155 kW. Since unlike the main house, the other facilities are not always being used, this information is important. The size of the boiler may be a problem during the summer, when the load demand is below 170 kW, forcing the the boiler to operate with low efficiency, as seen on the picture below.

This may be fixed using an appropriate control system even with current thermal buffer size.

Moving on, peak demand of 780 kW would require a secondary source of heat with capacity of 280 kW. The hotel already has two oil boilers installed with higher total capacity.

The size of the installed storage system is 4 000 L. Looking at the period where just the main house is being occupied, this storage can supply the mean hot water demand for 2 hours. Adding the fact that (for this case) the boiler is oversized, this configuration may force it to operate with very low efficiency. Of course, all depends on how the control system is working, or in other words, when the auxiliary oil boilers are being used. If they are used to supply hot water during summer, no problem will occur.

Important information is, because of a problem with the control system, and the impossibility to correct it, the oil boilers are not being switched on. The boiler will have to work by itself in all the situations described above. In order to work efficiently, it is necessary to avoid the boiler being turned on and off very often and to supply energy for its start-up process. Resizing the buffer to work in with this configuration, and having enough water to supply for 4 hour of the house mean demand, it is expected that at least 28 000 L of water are required, an amount 7 times higher than the one installed.

Another problem is that, with the oil boilers not working, the secondary source of energy is zero, against the one indicated as necessary by the tool (280 kW). This lack of energy, added with an undersized buffer system for this case, are probably the cause for the complains about the slow heating during cold nights, where the peak demand, that was expected to be supplied by the oil boilers, is having to be supplied by the biomass boiler and the thermal buffer.

The conclusion is that, although the system presents sizes that the tool indicates as inappropriate, they could be used depending on how the secondary boiler control was configured . Since this control is not working, the problems identified take place.