Biomass Boiler Case Study

Overview

This case study has been to chosen to analyse an existing housing estate and determine its suitability for the conversion of its heating supply to that of a biomass boiler system. A key criteria along with what the existing heating method is, is what available land there is for placement of the biomass plant. This is because the biomass plant is substantially larger in size than for alternate heating methods. This is due to the fact that the source of fuel has a large volume when compared to oil and gas, and this fuel has to be stored in reasonable amounts so that there is not a constant need for the delivery of fuel.

For this case study woodchip has been chosen as the fuel type as it is the most versatile fuel type that can be obtained from a wide variety of sources. Most modern biomass boilers can accept various wood types as fuel, which can include wood shavings, sawdust and energy crops such as short rotation coppice (SRC) and tree trimmings.

Along with Google Earth, an online mapping tool and the Carbon Trust Biomass Boiler Sizing Tool will be used to determine the housing heating demand and the related biomass boiler capacity and additional plant. These tools can be downloaded from the Biomass Boiler Workflow Tab in the Workflow page of this site. Go to Biomass Boiler Workflow

For approximate sizing of the biomass boiler and supporting equipment the dimensions contained in the Biomass Boiler Sizing Tool will be used, and also dimensions taken from equipment manufactured by European companies.

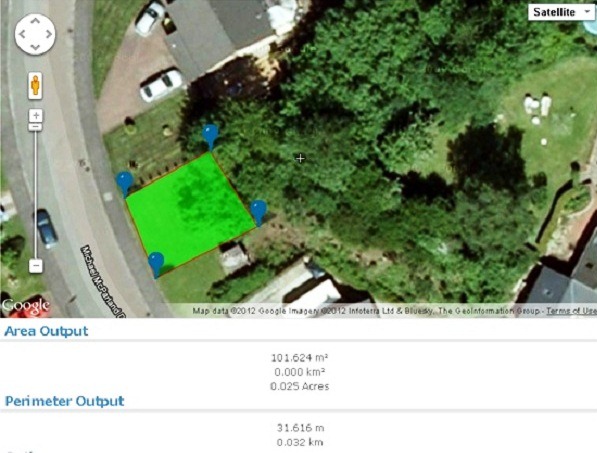

Shown above is a Google Earth image of the housing estate chosen for the biomass case study.

Technical Feasibility

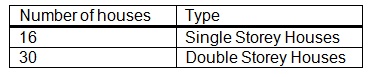

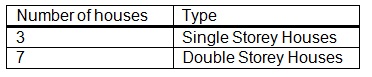

For the purpose of the case study analysis the housing mix has been broken down into two groups as shown in the table below.

To determine the area available to fit the biomass boiler plant the tool detailed in the workflow section of this website was used. The available area is shown in the image below.

The mapping tool has determined that the available area proposed for the biomass boiler site is approximately 100m². It can be seen from the image that the site has road access which is an important screening criteria as road access is required for the delivery of the biomass fuel.

The two types of buildings from the case study were entered into the demand module for the biomass sizing tool and the process outlined in the supporting manual was followed to arrive at the required boiler capacity to meet the demand of the site. The calculated boiler capacity for the whole site is 7,201kW which equates to an actual biomass boiler of 8MW.

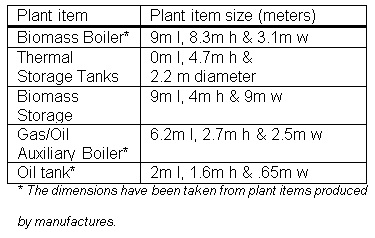

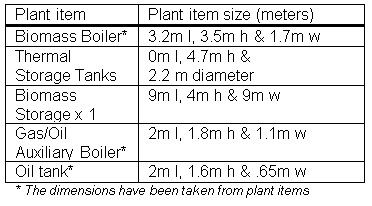

As previously discussed once the boiler capacity is known the dimensions of the boiler and additional supporting equipment can be obtained from industrial manufacturers, and also from the biomass boiler sizing tool. With this information the table shown below was produced.

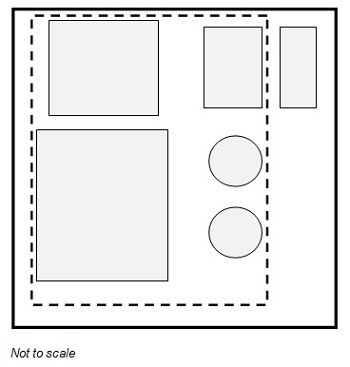

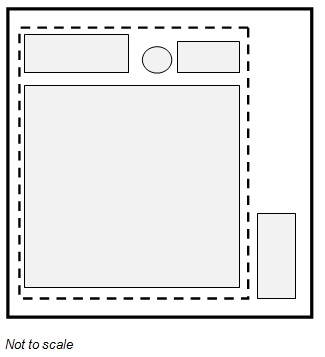

With the plant item size and access area around the itens the schematic below was produced which is used to determine the estimated footprint area of the building required to house the required plant items.

Using this estimate at how the biomass boiler plan may be laid out the area required for this biomass boiler configuration is at least 305m². As the site available is 100m² this size of plant clearly will no fit on the site. Rather than write off the possibility of installing a biomass boiler on this site the factor that can be modified to reduce the size of the plant is the demand.

To reduce the site demand the number and location of houses shown in the image on the right was chosen. The rationale for his selection was to restrict the number of houses and ensure that it included both housing types. Another important reason for choosing this selection is that the required district heating network(DHN) at no point has to cross a road or path as the DHN can be routed in the back yards.

The yellow circle in the above image is the proposed biomass boiler site and the red circles show the houses included in the reduced demand analysis.

The yellow circle in the above image is the proposed biomass boiler site and the red circles show the houses included in the reduced demand analysis.

The housing mix for the reduced demand is shown in the table below.

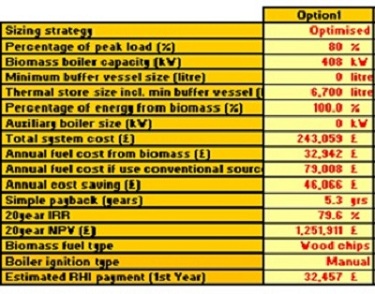

As with the previous housing mix this housing mix was entered into the demand module for the biomass sizing tool to obtain the required boiler capacity to meet the demand. The required biomass boiler capacity using this housing mix has been estimated as being 408kW, which equates to an actual biomass boiler of 500kW. Shown in the image below is the sizing information from the tool which details the percentage of peak load which the boiler has to meet.

The dimensions of the boiler and additional supporting equipment are shown in the table below.

With the plant item size the schematic below was produced to determine the estimated footprint area of the building required to house the required plant items.

The estimated total area required for this biomass boiler configuration is at least 99m². Therefore a 500kW biomass boiler plant can be installed to meet the demand of ten houses.

Financial Feasibility

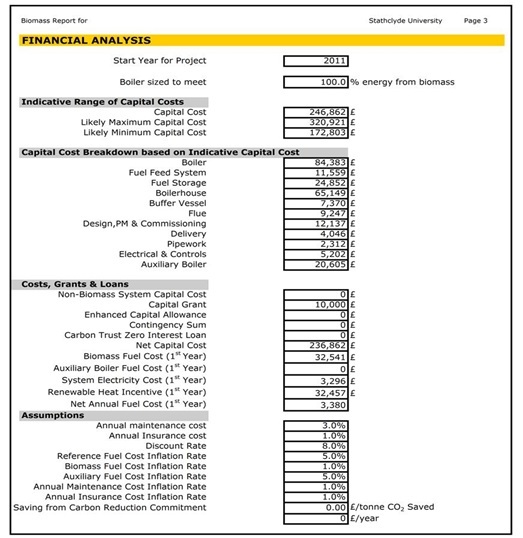

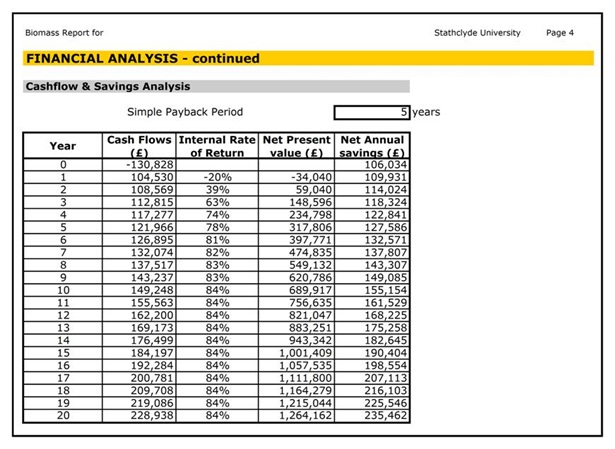

The Biomass Boiler Sizing Tool produces a report which includes a financial analysis information which is shown in the images below and on the right.

The RESCO will have to raise funds to pay for the biomass installation and also it will have to factor in the cost of installing the district heating network (DHN). All of this work can be put out to tender so as to obtain the most competitive price for installation.

© University of Strathclyde