Biomass Literature Review

Introduction

Biomass as a term covers a wide range of organic material created by animals and plants which are carbon based and whose carbon is obtained from carbon dioxide (CO2) in the atmosphere 1,2. The biomass scope for this project is limited to biomass material produced by plants.

Shown on the right are the government agencies in the UK who provide information and support on biomass issues.

The growing, processing and combustion of this biomass will now be discussed.

Biomass Sources

Biomass Cropping

Crops grown for the purposes of producing biomass are called energy crops and one of the most popular energy crops are short rotation energy crops, specifically short rotation coppice (SRC). These crops are harvested on much shorter timescales than for traditional forestry and the annual rate at which their biomass increases is high in the early years of growth 3.

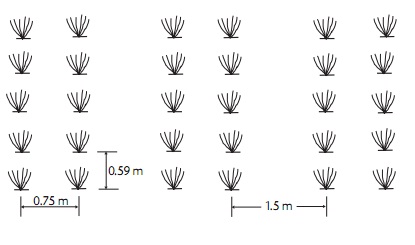

Willow SRC is suitable for growing in Northern European countries and it has also historically been grown for the production of traditional woodland products such as baskets and fences 4. After a site is prepared specialist equipment is required to plant the willow seedlings or short pieces of willow stem. Typical planting density of willow SRC is shown in the image below.

Source 5

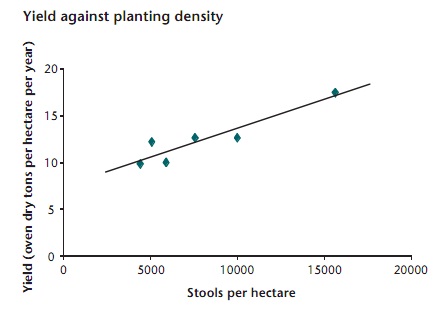

Shown below is a graph detailing anticipated yields from different planting densities, with the yield measured in ordinary dry ton (odt).

Source 5

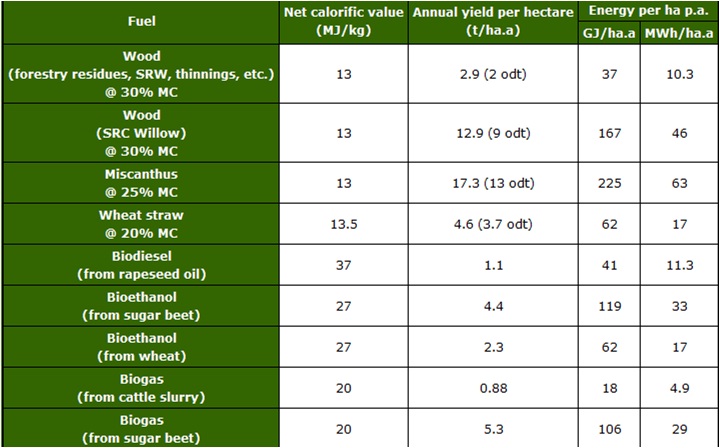

In addition to planting density SRC crop yield is also dependent on the availability of water, light levels and whether weeds are controlled 6. For comparison shown below is the yields and estimated energy value of various fuel types.

Source 7

Willow SRC crops can also be grown on land which is contaminated with heavy metals as the contaminants remain in the root balls of the willow plants 8, which means that instead of using valuable agricultural land brown field sites can also be used for energy production.

Cropping of the SRC crop is undertaken by specialist equipment and is termed as coppicing. This first occurs after the first year when the willow rods are up to 8m in length, and then occurs every three years for 15 to 20 years 9, 10.

Biomass Sources

Arboricultural Arisings

Another type of biomass available in the UK is what is called arboricultural arisings which is obtained when trees are maintained and is composed of numerous small dimensioned branches and twigs 11. A study commissioned by the Forestry Commission of Scotland estimated that there was 700,000 tonnes of arboricultural arisings which could be used as a source of biomass fuel 12.

Obtaining useful biomass from arboricultural arisings has been pioneered by plants called TreeStations which work in partnership with local tree surgeons to produce woodchip from their waste 13.

Other Sources

Other sources of biomass include food waste which includes organic waste left over from the brewing industry and industrial waste which can include wooden pallets and combustible packaging material 14.

These alternate sources are widely available across the UK and in most cases are a waste produce and their use to create energy would negate the need for alternate disposal.

Processed Biomass Fuel Type

Biomass must be processed from its raw unprocessed from into a form that is easily combustible. The raw material must also have its moisture content reduced to a minimum of 30% to reduce weight and also to reduce the amount of ash that remains after combustion has taken place.

For the purposes of this project two types of biomass fuel types will now be introduced.

Woodchip

Woodchips can be produced from a wide variety of sources such as forestry waste, arboricultural arisings and industrial waste products. Due to their lack of uniformity of size they are not suitable for automated biomass boiler systems. Woodchip moisture content needs to be reduced to 30% to reduce the ash left post combustion 15.

Wood Pellets

Wood pellets are made from waste such as sawdust and cut offs generated from wood processing and they have a moisture content of 8 to 10%, and are denser than woodchip. Another advantage of wood pellets is that they are of uniform shape which makes them very suitable for automated biomass boiler feed systems 15.

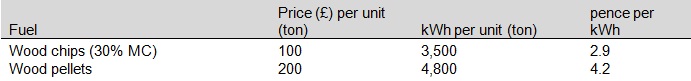

Shown below is a price comparison between the two biomass fuel types showing that the price for wood pellets are more than double that of woodchips.

Biomass Boilers

The burning of biomass in an enclosure whose air flow is restricted is the simplest means of releasing the energy from biomass 17.

Biomass boilers typically have rated efficiencies of 80% and are categorised by which type of biomass fuel they use. The four main biomass boiler types are log, pellet, chip and combination with the later accepting the three prior biomass types as fuel 15. .

Woodchip boilers are the most suitable for medium to large scale installations and as discussed earlier woodchip size and moisture content are important variables which determines the boilers efficiency. Most manufactures produce woodchip boilers down to 40kW in capacity however they are available down to a capacity of 25kW 18.

Pellet boilers are more suitable for smaller installations due to their capacity range which starts from 15kW and has no technical upper limit, as power stations can be ruin from pellet boilers. Another advantage of wood pellet boilers is that the fuel store is smaller due to pellets having being denser and having lower moisture content 19.

Incentives

Grants are available for the planting of biomass crops and also for the installation of biomass boilers as detailed in the following webpage Biomass Energy Centre information on grants.

The UK government is also providing an incentive program called the Renewable Heat Incentive (RHI) which is detailed in the following webpage Renewable Heat Incentive (RHI).

References

1. www.biomassenergycentre.org.uk/portal/page?_pageid=76,15049&_dad=portal&_schema=PORTAL

2. Twidell, J. & Weir, T., 2006. RENEWABLE ENERGY RESOURCES. 2nd ed. Oxon: Taylor & Francis.

3. www.biomassenergycentre.org.uk/portal/page?_pageid=75,17369&_dad=portal&_schema=PORTAL

4. www.biomassenergycentre.org.uk/portal/page?_pageid=75,18092&_dad=portal&_schema=PORTAL

5. www.forestry.gov.uk/PDF/fcpn7.pdf/$FILE/fcpn7.pdf

6. www.biomassenergycentre.org.uk/portal/page?_pageid=75,18112&_dad=portal&_schema=PORTAL

7. www.biomassenergycentre.org.uk/portal/page?_pageid=75,163231&_dad=portal&_schema=PORTAL

9. www.biomassenergycentre.org.uk/portal/page?_pageid=75,18112&_dad=portal&_schema=PORTAL

11. www.biomassenergycentre.org.uk/portal/page?_pageid=75,18521&_dad=portal&_schema=PORTAL

13. www.4ecotips.com/eco/article_show.php?aid=670&id=279

14. www.biomassenergycentre.org.uk/portal/page?_pageid=75,15174&_dad=portal&_schema=PORTAL

16. www.biomassenergycentre.org.uk/portal/page?_pageid=75,59188&_dad=portal&_schema=PORTAL

17. www.biomassenergycentre.org.uk/portal/page?_pageid=75,225219&_dad=portal&_schema=PORTAL

18. www.biomassenergycentre.org.uk/portal/page?_pageid=75,363210&_dad=portal&_schema=PORTAL

19. www.biomassenergycentre.org.uk/portal/page?_pageid=75,357183&_dad=portal&_schema=PORTAL

© University of Strathclyde