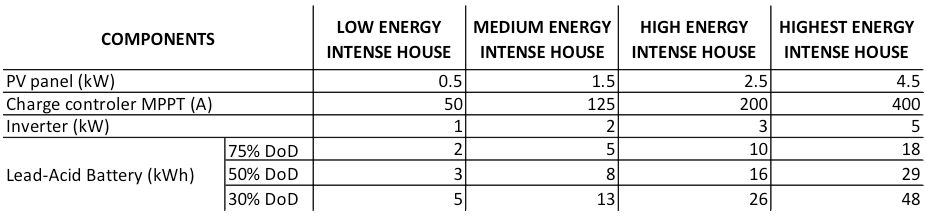

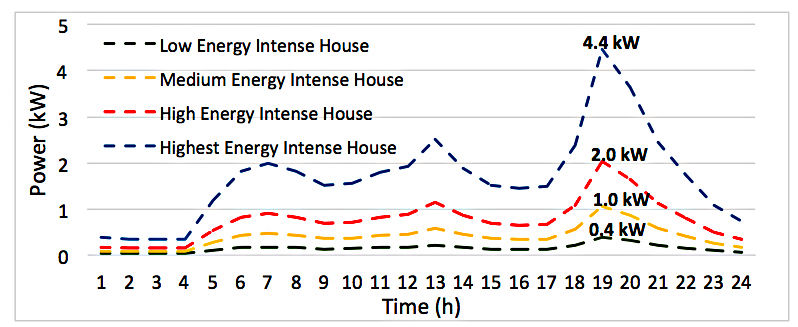

To be able to size the PV system with storage, load curve profiles for the typical houses in Mian Channu mentioned in the current situation section were generated. The size of all components of PV system and storage was selected according to the ordinary domestic load profiles during the summer shown in Figure 1.

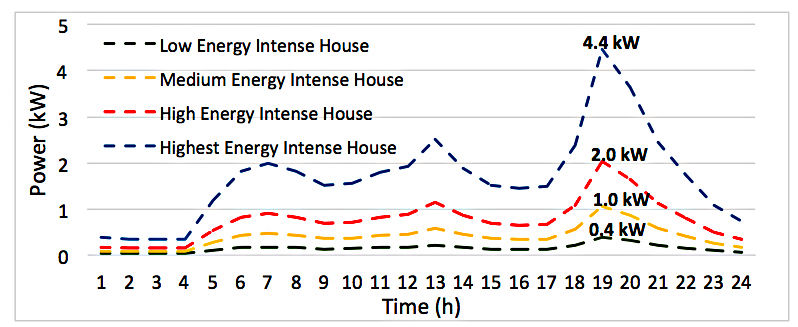

The following boundaries shown in Table 1 are applied in order to perform this analysis. The features related to the lifetime and depth of discharge of the sealed lead acid battery are expressed in ranges because it depends on specific settings when sizing the PV system. Further analysis on these features will be presented in the next section.

When sizing the PV system, the consideration of the cost of components is very important, but the lifetime of components also plays an important role. In this context, the main constraint in our system is the sealed lead-acid battery as its lifetime is affected by many factors.

The sealed lead-acid battery is selected because it is the most affordable option within the battery options available in the market. Despite the benefits in terms of cost, the sealed lead-acid battery has limitations regarding its lifetime. There are many factors that influence the lifetime of batteries, but for this specific study only the influence of temperature and depth of discharge is considered.

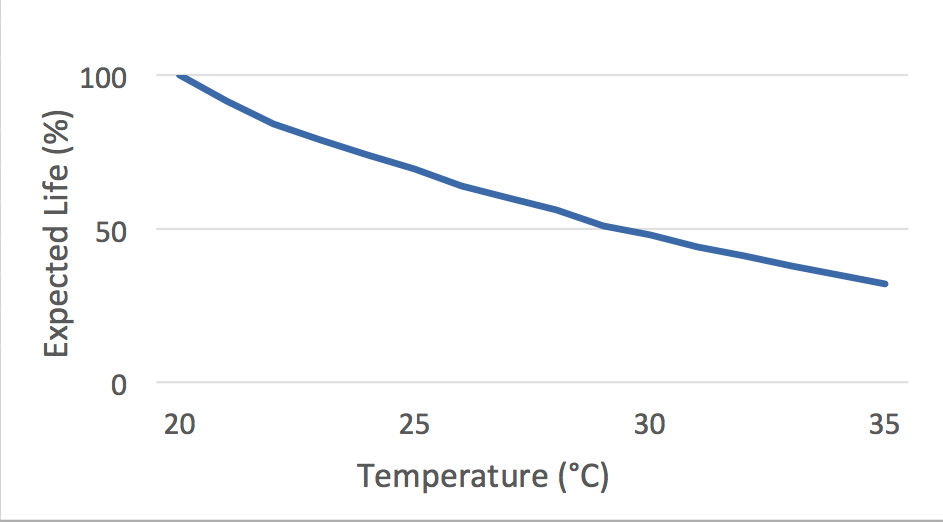

Influence of temperature

All batteries achieve optimum service life if used in working temperatures somewhere between 20°C and 30°C. The performance and the lifetime of a battery can be seriously affected by the increase in temperature (Sauer et al., 2008). Figure 2 shows the effect of temperature on the expected lifetime of the battery. The effect of temperature is considered relevant because Mian Channu is characterized by hot climate with daytime temperatures above 30°C during the summer.

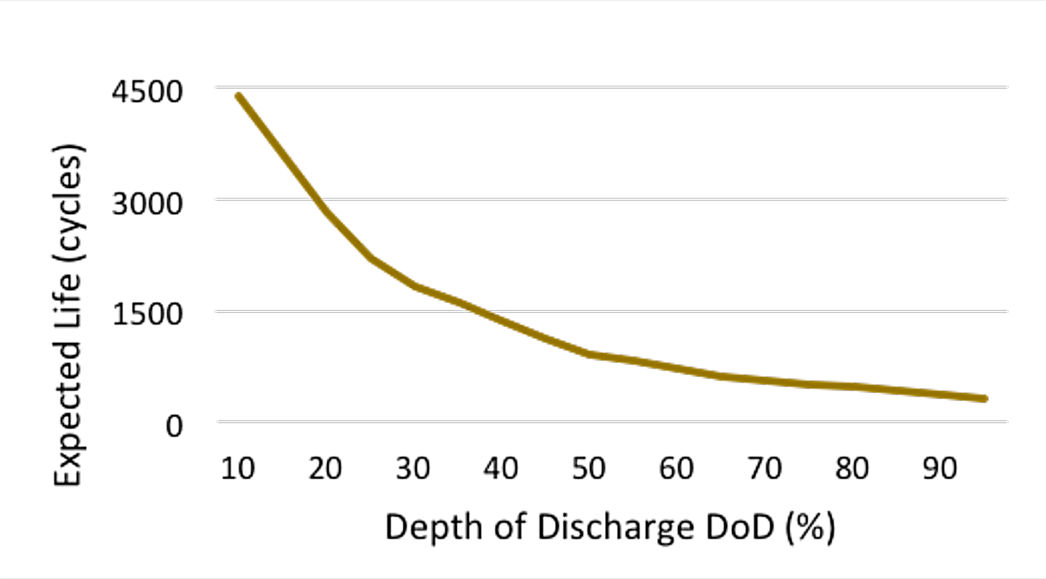

Influence of depth of discharge

Most sealed lead acid batteries experience significantly reduced cycle lifetime when discharged more than 50% (Zhang et al., 2017). In this case, it is important to analyse the pattern of depth of discharge along the year and then define the most appropriate size of the battery with a respective depth of discharge. Figure 3 shows the effect of depth of discharge on the expected cycle lifetime of the battery. The effect of depth of discharge is considered relevant because it is intrinsically related to the size of the battery bank needed for the PV system.

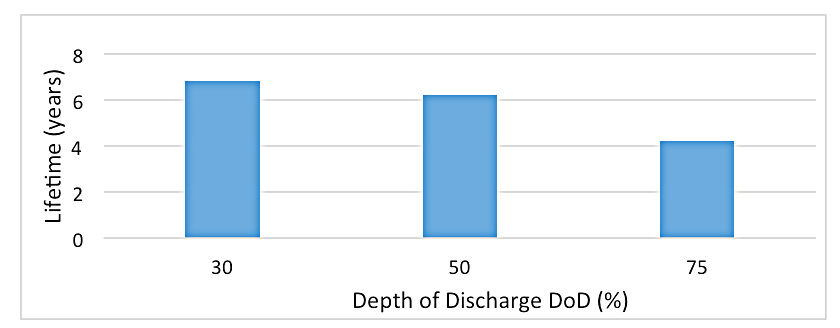

The lifetime of the battery considering the combined influence of temperature and different depths of discharge along the year is shown in Figure 4. As expected, the lifetime of the battery reduces as the depth of discharge increases.

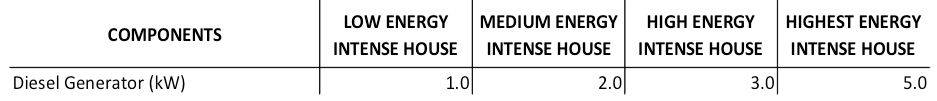

The diesel generator and PV system with storage are sized according to the load curve profile illustrated in Figure 1. Table 2 presents the size of the diesel generator for all four different typical houses in Mian Channu.

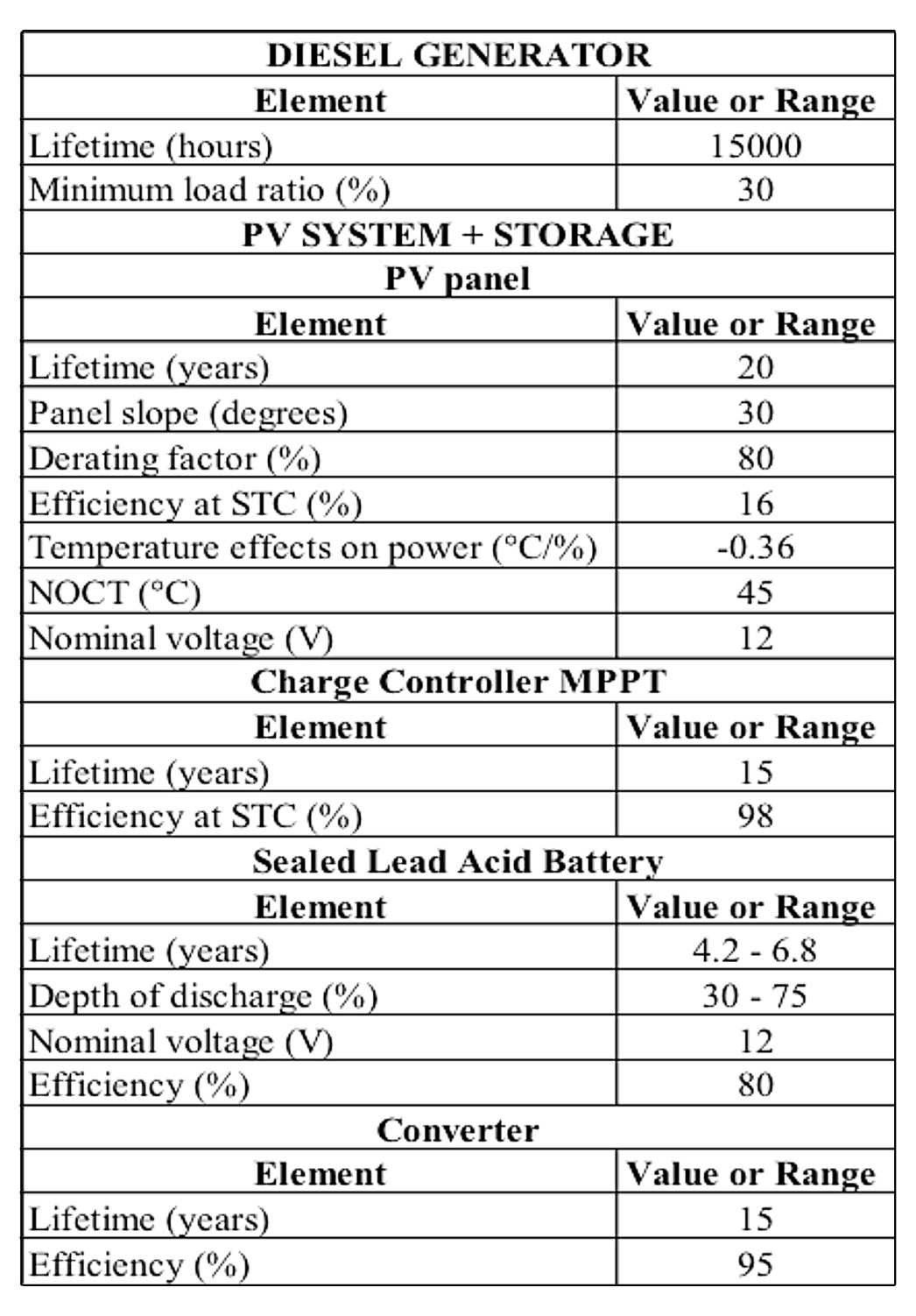

Table 3 present the size of the PV system for all four different typical houses in Mian Channu. The PV system includes PV panels, a charge controller MPPT, an inverter and a battery bank.