- General Considerations

- Specific Considerations

Biomass – Assessing the Potential in Rural Areas

Biomass Boiler

The initial assessment to determine the practicalities of installing biomass heating involve technical and economic considerations. This will help the site owner decide whether to carry out a more detailed feasibility study. Biomass heating systems generally have higher initial capital cost than fossil fuel systems of equivalent rated capacity. However, this difference can be recouped through annual fuel cost savings.

Technical Considerations

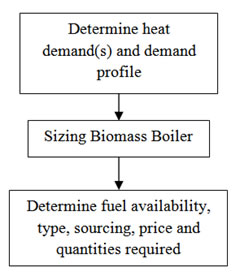

Technical considerations is one of the most important steps when considering installing a biomass boiler. The procedure in the flow chart below is interrelated and necessary to follow.

Figure 1. Biomass Heating Technical Consideration framwork

Determine site heat demand(s) and demand profile

It is very important to evaluate the heat demand profile that the biomass heating system will be required to meet, so the system can be correctly sized. The basic methodology for evaluating the energy demand in rural location can be found in the Methodology for assessing energy demand section.

Sizing BoilerBiomass boilers in many ways are very similar to traditional boilers, with efficiency around 80 - 90%. They do have some important considerations though. One important characteristic that must always be taken into consideration is the turn-down ratio of these boilers.

More specifically when using wood as fuel, it is necessary to have it very dry to initiate and maintain the combustion at a high level of efficiency. This is done using the energy generated by the boiler itself (or during start-up period through a secondary source of heat), stored in the thermal lining, to dry the wood chips or pellets entering the combustion chamber. This is the reason why below a given power output, the boiler loses efficiency, the combustion process usually is not complete and the emission levels increase. The relationship between the maximum and the minimum power output for which the best efficiency is maintained is called turn-down ratio. For wood chip and wood pellet boilers this value is around 30%, being able to reach 25% when dealing with very dry fuel.

Because of the limited range of power which is defined by turn-down ratio in which a biomass boiler may operate - more specifically because the need for the pre-drying stage inside the boiler - biomass systems are not suitable to deal with peak demands. Sizing a boiler based on the peak demand would cause its minimum power output to be too high, maybe even close to the mean demand, forcing the boiler to work most of the time with low efficiency, or not work at all. It is important to take this into consideration when selecting the boiler. In most cases a backup system must be present to support the biomass system during the peak demand. (Assessing Biomass Feasibility, University of Strathclyde, 2007)

Economic Consideration

To assess the economic feasibility, there are several important parameters that the site owner needs to be aware of:

- Site’s annual energy consumption.

- Heat demand profile (utilisation patterns).

- Costs associated with fossil fuel use.

The outputs of this economic evaluation are included in the results that can assist in considering whether the biomass boiler is practical in the first instance. These results consist of:

- Total capital investment required (£).

- Simple payback (years).

- Unit cost of heat from the project (p/kWh).

- Annual energy cost (£/year).

The basic economic feasibility assessment can be calculated by using some online tools that are available on the internet, such as the tool from CarbonTrust or the tool that has been developed by the previous years group project that can be download from this website. Some of the information and format of the calculator tool in that website was used as the reference for our calculation tool that we have developed to use in this project that can be downloaded here.

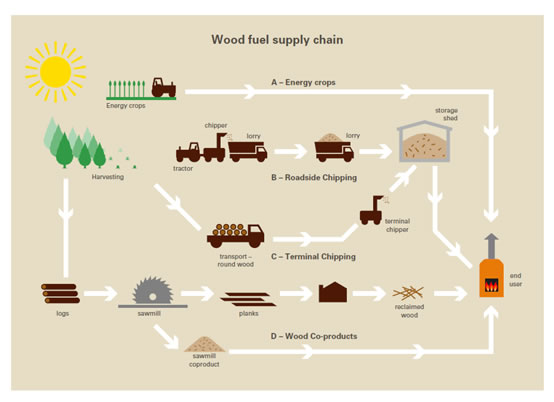

Wood Fuel Supply Chain Option

Potential supply chain options are shown in the figure 2. As illustrated, the wood fuel supply chain covers a large range of industries including: forestry, farming, timber processing, machinery and equipment manufacturers and dealers. To develop a robust wood fuel industry, those in the supply chain need links with the heating equipment manufacturers, suppliers and installers; energy supply companies; consultants; transport and advisory and grant-awarding bodies. The increased use of woodfuel in Scotland depends on all these elements being accessible. The development of clusters of these resources across Scotland will aid the development of the woodfuel.

Figure 2. Biomass Heating Technical Consideration framwork

Source: http://www.usewoodfuel.co.uk/Sourcesofsupply.stm

When considering a fuel supply for rural areas - particularly in the south west of Scotland - Dumfries and Galloway was considered. There are three supply options available:

- Contract Locally

- Energy Service Company

- Self Supply

The first option, contract locally, would require purchasing wood fuel from local suppliers, such as forestry owners and contractors, sawing mills, fuel merchants or fuel supply co-operatives.

The Forestry Commission is a good place for supplying wood fuel because around 17% of Scotland’s land is covered in forestry and about 35% of this forestry cover is owned by the Forestry Commission. However, there are also opportunities to obtain wood fuel from private forestry owners, and also from specific suppliers for wood chip, wood pellets, etc. There are totally around 6 million m3 of timber per year. Production could increase to around 10 million m3 of timber per year over the next 10 to 15 years, with most of the addition potential volume in the private sector.

The national forest estate is managed by Forest Enterprise Scotland (FES), which is part of the Forestry Commission. Over one third of FES annual production is sold on the open market. Since mid 2004 the majority of these sales have been conducted electronically through the FC website

(www.forestry.gov.uk/business). Contact details for your local Forest District can also be found on the FCS website.ConFor is the main industry body for private sector forestry. ConFor's remit covers all parts of the industry supply chain, from timber growers, through to harvesters, sawmills and other processors.

Another option would be to obtain wood fuel from an Energy Service Company. In this case the customer is billed, at an agreed price. The Energy Service Company usually operates and maintains the boiler and can either own the boiler or lease it from another company. The advantage of buying heat and other services from an ESCo is the little input that the final user needs to have with the installed biomass system, thus negating any worry about maintenance and fuel supply that a biomass boiler may pose. The time period of a contract can be seen as a disadvantage when buying services through an ESCo as the tariff may not stay competitive.

For using ESCo’s options, there are a number of different contracts - fuel suppliers, equipment suppliers that depends on which heat or fuel is going to be bought.

References

- Biomass Project, MSc. Renewable Energy System and Environment, University of Strathclyde,

http://www.esru.strath.ac.uk/EandE/Web_sites/06-07/Biomass/HTML/index.htm

- Carbon Trust, 2009., Biomass heating A practical guide for potential users, uk., www.carbontrust.co.uk

- http://www.usewoodfuel.co.uk/Sourcesofsupply.stm

- http://www.usewoodfuel.co.uk/Contract%20Options.stm

- http://www.biogas-info.co.uk/index.php/ad-calc-agri

| MSc: Renewable Energy Systems and the Environment | © University of Strathclyde 2010 |