- General Considerations

- Specific Considerations

Biomass – Assessing the Potential in Rural Locations

Anaerobic Digestion

Anaerobic Digestion (AD) is a natural process and is the microbiological conversion of organic matter to methane in the absence of oxygen. Beside the energy - in the form of heat and electricity from the conversion of biogas - generated from anaerobic digestion process, the other by-products are encouraging for the small scale installation in rural locations (for economic and/or environmental reasons). Digesters represent a way for the farmer to convert a waste product into an economic asset, while simultaneously solving an environmental problem.

Anaerobic digestion source supply

Any high-rated biodegradable waste can be decomposed as a methane generator - soft material is better than woody material. Animal waste is the most suitable in rural locations. Human waste and food waste - if the amount is enough - can be a practical supply as well. Each kilogram of biodegradable material yields around 0.4 m3 of biogas. Therefore, small scale AD systems can be practical if enough waste material is available. (www.small-farm-permaculture-and-sustainable-living.com)

Technical Considerations

Anaerobic Digestion from Animal Waste

For considering an anaerobic digestion system from animal waste, the single most important point to understand is that each farmer’s situation is unique and requires careful consideration of many factors. Anaerobic digestion systems can be quite costly to install, so the owner should fully understand the purpose of the system and its economics.

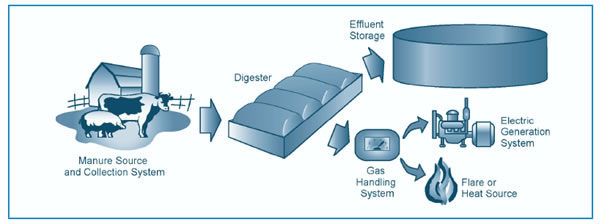

Figure 1. Anaerobic Digestion Process

Source: United State Environmental Program Agency, EPA, 2002 (www.epa.gov)

The size of the system is determined primarily by the number and type of animals served by the operation, the amount of dilution water to be added, and the desired retention time. The most manageable of these factors is retention time; longer retention times mean more complete breakdown of the manure contents, but require a larger tank.

To determine if a biogas recovery system is right for your facility, you will need to consider the following factors: how manure is handled at your facility, the frequency of manure collection, and the options available for using the recovered biogas.

- Manure handling. Biogas digester systems can accommodate manure handled as a liquid, slurry, or semisolid (with little or no bedding added). The total solids content of the manure - a measure of manure thickness - determines these classifications.

- Frequency of manure collection. Facilities best suited for biogas digester systems typically have stable year-round manure production, and collect at least 50 percent of the manure daily.

- Gas use. Several gas-use options are available, including engines, chillers, and boilers, or gas can simply be flared. When choosing among these options, you will need to take into account how the option affects a system's financial performance, the labour requirements associated with the option, and the skills needed to maintain and repair energy producing equipment.

The cost of an anaerobic-digestion system can vary dramatically depending on its size, intended purposes, and sophistication. Livestock producers can choose from a wide range of waste management options provided by a variety of agricultural engineers, vendors, and equipment suppliers. The costs of these options can vary greatly, in terms of both initial investment and annual operation and maintenance.

The Calculator Spreadsheet for evaluating the potential (including the economic analysis) of biogas from anaerobic digestion systems can be download here. This calculator tool for anaerobic digestion is developed by The Andersons Centre, 2007 which is available on this website.

References

- http://www.biogas-info.co.uk/index.php/ad-calc-agri

- United State Evironmental Program Agency, 2002., Managing Manue with Biogas Recovery Systems, Office of Air and Radiation, USA.

| MSc: Renewable Energy Systems and the Environment | © University of Strathclyde 2010 |