There are not many projects which have been carried out on decommissioning for OWTs. There is a notable lack of experience and a great deal of uncertainty in this area. These factors increase the costs of the project because the installers have difficulty in predicting the funds to be set aside for future decommissioning as required. This shows the necessity for developing more studies to ensure the decommissioning is feasible, economic and has a low impact in the environment.

To decommission a wind farm out at sea is more complicated than on land. The methods used will depend on the type of foundation to be dismantled. The experience from the oil and gas industry can help to plan the decommissioning process (Oil & Gas UK, 2012). Consideration must of course be given to the local marine environment and the knowledge available at the time of decommissioning.

The decommissioning of wind turbines can be seen almost as a reversal of the construction process although there are aspects of offshore decommissioning that do not apply to onshore, such as the need for barges or platforms for removal and the added constraint of part of the turbine as well as the foundations being below the water level.

For an offshore wind turbine, the majority of the cost of decommissioning is therefore significantly higher than the equivalent onshore wind turbine.

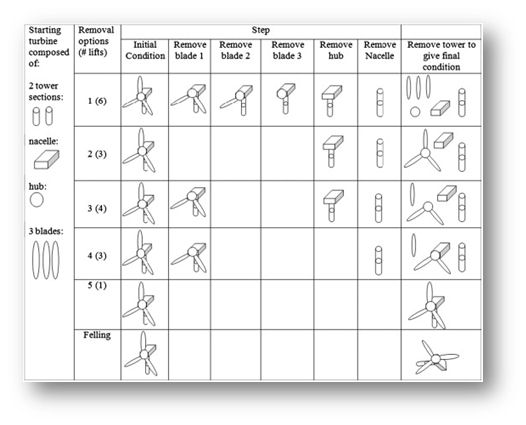

In the figure (Kaiser and Snyder, 2012) can be seen the different removal options. In terms of costs, option 5 which only requires one lift with the crane and the felling option would be the cheapest, although the felling option may cause unwanted damage to the turbine and limit the reuse or recycling of materials. Generally, the tower and nacelle would contain copper which has a high resale value.

FOUNDATIONS - other issues which will need to be considered

There are other issues which will need to be considered when evaluating the best decommissioning strategy for offshore wind farms, such as the foundations only being removed to a certain depth (Oil & Gas UK, 2012). Depending on the size and weight of the jacket, it can be fully removed or partially removed to the top of the footings.

Although fully removing the foundations will cost more and take more time, from an environmental point of view it would fully restore the site. However, there are also environmental enhancement options which could potentially utilise the foundations.

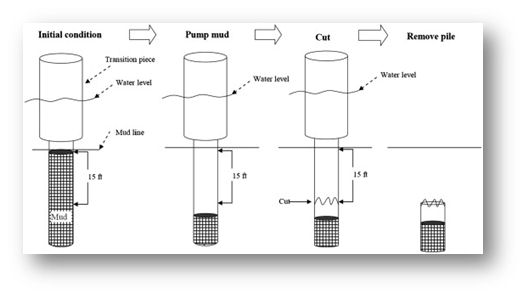

The process of extracting the jacket involves cutting the piles that attach it to the seabed and taking the complete structure to shore. The piles are cut 15 ft below the mudline and removed by a single lift such as crane vessel (Figure 2 - Removal for a jacket foundation, (

(Kaiser and Snyder, 2012)