Feasibility of Maintaining Performance

As discussed there are many options for maintaining blade performance. To ensure that protection options are economically feasible the group selected a coating with a one year lifetime. This selection is based on the ability to recoat during an annual scheduled maintenance. The coating is quoted at £103/2.5L, covers 10m2/L, contains antifouling, is applied in 4 coats, and does not require primer. Assumptions made by the group include the following:

- Rate of a skilled tradesperson = £40/hr

- Time required to apply one coat = 1hr

- Amount of blades on a rotor = 5

- Amount of turbine in farm = 24

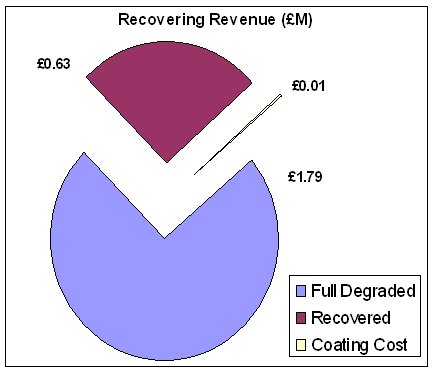

With these assumptions the group calculated that the additional cost to recoat a farm of rotors while they are out of the water for maintenance is about £10,000. This is a small proportion of the total revenue that can be earned by a farm of this size. A pie chart depicting the revenue earned by a farm of degraded rotors, the cost of recoating those rotors and the recoverable revenue follows.

These values represent the calculated revenues that are presented in the previous financial study of blade surface degradation. This is evidence to show that the cost for an operator to protect its blades is marginal compared to the drop in revenue that they are likely to experience if they fail to maintain them. In conclusion, the benefits from investing in protective coatings are likely to be considerable.