Data Centres and Renewable Energy Project

Wind combined with biogas

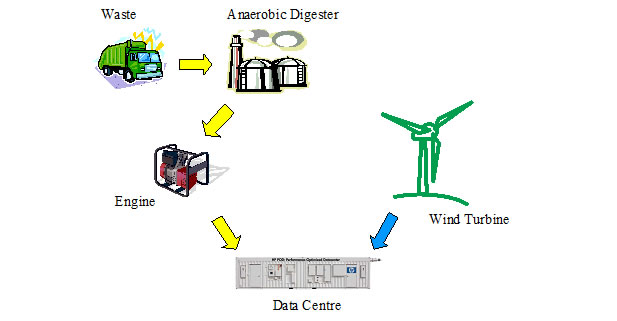

Principle of Operation

Wind turbine generates electricity, anaerobic Digester processes organic waste from surrounding area to produce biogas, which is stored Gas is burned in an engine to produce electricity when the wind is not strong enough

Technology/ Devices

For Shetland wind conditions:- 1.5 MW wind turbine

- AD plant with 1250 t/month capacity for mixed wet waste or 330 t/month sorted organic dry waste

- Gas engine of 320kWe

- Tanks for storing 58,500m3 gas

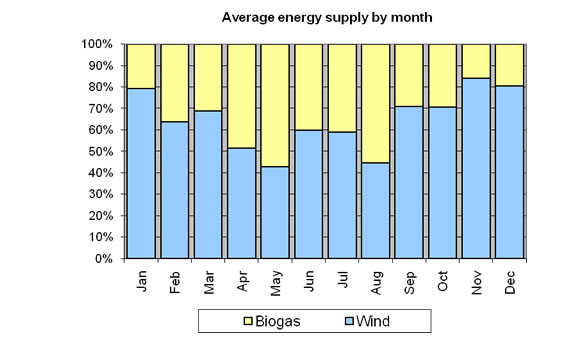

In this scenario, 65% of annual energy comes from wind, 35% from biogas

Biogas is being used to supplement wind 50% of the time; the rest of the time excess electricity is produced. The wind turbine selected is the maximum size that can attract Feed-In Tariffs at 10.1p/kWh rate.

This is a good solution environmentally because less material goes into landfill and 50% of the potential methane from waste is converted to the less harmful CO2 (1).

Requirements

Average wind speed 7.4 m/s (Lerwick conditions)

Sufficient population to produce enough domestic waste and sewage – and helpful if agricultural waste or food processing wastes were available. Examples: fish processing waste, distillery by-products, seaweed from fish farms. For example, Shetland produces 42,000te/year waste of which 17,000te/year goes to landfill (2).

For production of biogas, Anaerobic Digestion is the preferred technology because the biochemical process can work on a variety of feedstock (food waste, human waste, manure, or a mixture etc (3) whilst gasification, a thermal process works best on feedstock with a more woody content (4).

Key assumptions

Wind turbine (5) GE sle 1.5MW turbine

Cut-in speed: 3.5m/s

Cut-out speed: 25 m/s

Rated speed: 14 m/s

Anaerobic Digester parameters (6):

Process: mesophilic, requiring temperatures between 20-40ºC

Energy content of biogas: 25 MJ/m3

Gas production from feedstock:

- 150m3 /t sorted wastes with 30%+ solids content

- 40m3 /t mixed wastes with 10-15% solids content

These are conservative parameters relative to other reported values in a recent survey of the technology (6), or other reported values by the FAO (7), or by a consultancy (8)

AD Production safety margin: 20%

-> this is to cover for the possibility that there may be fluctuations in wind strength and duration between years

Gas engine

Efficiency: 30%; 475,000 te biogas required per year

Gas engine waste heat used to heat AD process

Calculations can be found in this spreadsheet.

Issues

- Wind is highly intermittent – turbine is standing still around 20% of the year, equivalent to 70 days a year

- Limited feasibility to scale up because region does not have very large population or industry

- Excess electricity is produced at peak times, which could be used locally – amounts to 63% of data centre requirement

- Revenues from gate fees depend on level of landfill tax (9) – currently £45/t

References used in this page:

(1) Anaerobic Digestion 2010 : How to Estimate Biogas from Anaerobic Digestion of Organic Solid Waste; http://anaerobic-digestion.com/html/how-to-calculate-greenhouse-ga.php, accessed 28 April 2010

(2) Letsrecycle.com 2002: Orkney and Shetland commit to energy from waste for the next 20 years; http://www.letsrecycle.com/do/ecco.py/view_item?listid=37&listcatid=292&listitemid=3097 , accessed 20/04/2010

(3) Anaerobic Digestion What is Anaerobic Digestion? http://www.biogas-info.co.uk/, accessed 10/03/10

(4) Biomass Energy Centre – Gasification: http://www.biomassenergycentre.org.uk/portal/page?_pageid=75,17504&_dad=portal&_schema=PORTAL accessed 10/03/10

(5) GE 1.5MW sle turbine technical brochure

(6) deMes, T Z D; Stams, A J M; Reith, J H; Zeeman, G: Methane production by anaerobic digestion of wastewater and solid wastes; in: Bio-methane and bio-hydrogen, ed J H Rieth, RH Wijffels & H Barten, Dutch Biological Hydrogen Foundation 2003

(7) FAO 1997: A system approach to biogas technology; http://www.fao.org/sd/Egdirect/EGre0022.htm, accessed 21 April 2010

(8) Zorg Ukraine Ltd 2010 Biogas plant for sorted municipal solid waste http://www.zorg-biogas.com, accessed 30 March 2010

(9) http://www.defra.gov.uk/environment/waste/strategy/factsheets/landfilltax.htm