Data Centres and Renewable Energy Project

Biomass Combustion

Biomass combustion is a simple, proven technology. Biomass boilers work best at constant power so are well suited to provide a data centre’s needs. The plant will however need to be shut down for cleaning and maintenance at least once a quarter, and the data centre will be running on backup diesel during this time – between 4-20 days/year (3), (4).

As a by-product of electricity generation, enough hot water will be produced to heat about 12 households.

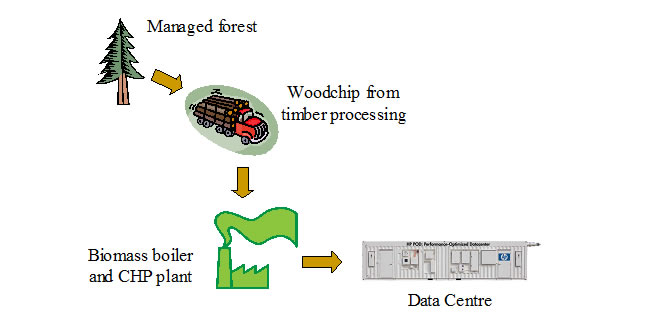

In the North of Scotland where there is limited agriculture but extensive managed forests, woodchip from managed forests is the most widely available fuel.

Requirements

- around 950ha of managed forest, and timber processing in the vicinity- backup diesel generator with fuel to last at least 3 days

Key assumptions

Fuel (1): average calorific value of seasoned wood: 13 MJ/kg

(in comparison, green wood is 8MJ/kg, dry wood is 16)

Average bulk volume of softwood chips (2): 5.5m3/t

Efficiency of electricity conversion (2): 20%

Boiler heat used for completing drying wood: 15%

Boiler maintenance:

- high quality, highly optimised boiler(3): 1 day shutdown every 13 weeks

- rugged, flexible boiler (4): 1.5 days every 4 weeks

Energy yield of land area (2): 6t dry matter per ha per year

- assuming that conifers are slower growing so will yield about half of what poplar or willow do in terms of te

Woodchip and waste production (2): 50% of total timber, rest is high-value wood products

Calculations are in the attached spreadsheet

Issues

- Unless both the forests and the timber processing plant are nearby, woodchip will have to be transported by truck. This makes it not a wholly renewable source and not carbon neutral, as well as adding to the expense.

- 65% of the energy is produced as hot water. This is a profligate form of electricity production unless this waste heat can be used locally for district heating or industry

- Small CHP plants are less efficient producers of electricity than large steam turbines, and they have no subsidy in the form of Feed-In Tariffs (5)

References used in this page:

(1) Twidell, J; Weir, T: 2006: Renewable Energy Resources, 2nd ed, Taylor & Francis, pg 38

(2) McKendry, P: 2002: Energy production from biomass (part 1): overview of biomass, Bioresource Technology, vol 83 pp37-46

(3) Personal communication by engineer from Buccleuch Environmental Services, during site visit to Queen Margaret University 1.5MW Biomass boiler, 24 February 2010

(4) Personal communication by engineer from Pentland Biomass, during site visit to Pentland Plants Biomass 2MW Biomass Boiler, 24 February 2010

(5) DECC 2010: Feed-in Tariffs: Government’s Response to the Summer 2009 Consultation, Dept of Energy & Climate Change, February